© Titan Tool Inc. All rights reserved.

23

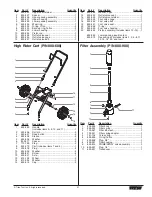

Accessories

Airless Tip Selection

Tips are selected by the orifice size and fan width. The proper

selection is determined by the fan width required for a specific

job and by the orifice size that will supply the desired amount

of fluid and accomplish proper atomization.

For light viscosity fluids, smaller orifice tips generally are

desired. For heavier viscosity materials, larger orifice tips are

preferred. Please refer to the chart below.

The following chart indicates the most common sizes and the

appropriate materials to be sprayed.

Fan widths measuring 8" to 12" (20 to 30 cm) are preferred

because they offer more control while spraying and are less

likely to plug.

Liquid Shield Plus

Cleans and protects spray systems against rust, corrosion and

premature wear.

Part No.

Description

314-483 ...........4 ounce bottle

314-482 ...........1 quart bottle

Piston Lube

Specially formulated to prevent materials from adhering to the

piston rod, which becomes abrasive to the upper seals. Piston

Lube will break down any material that may accumulate in the

wet cup and keep it from drying.

Part No.

Description

314-481 ...........4 ounce bottle

314-480 ...........8 ounce bottle

Miscellaneous

Part No.

Description

490-012 ...........Hose coupling, 1/4" x 1/4"

730-397 ...........High pressure fluid Gauge

314-171 ...........Lubriplate, 14 ounce individual

314-172 ...........Lubriplate, 6 lb. can

Tip Size

Spray Material

Filter Type

.011 — .013 Lacquers and stains

100 mesh filter

.015 — .019 Oil and latex

60 mesh filter

.021 — .026 Heavy bodied latex and blockfillers

30 mesh filter

NOTE: Do not exceed the sprayer's recommended

maximum tip size.

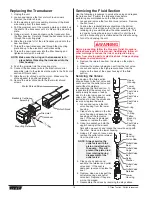

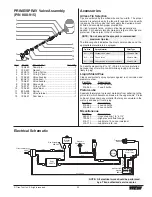

Electronic

Control Assy

Indicator Lights

Assembly

800-278

BLACK/RED/WHITE

BLACK

RED

WHITE

BLUE/YELLOW

GRAY/PURPLE

Transducer

800-449

BLACK

WHITE

WHITE

WHITE

BLACK

BLACK

BLACK

ORANGE

ORANGE

GREEN

Wire Assembly

800-368

Ground to

Gear Housing

Circuit

Breaker

765-327

Plug

Relay

800-276

Potentiometer Assy

800-277

Motor

Electrical Schematic

NOTE: All electrical work should be performed

by a Titan authorized service center.

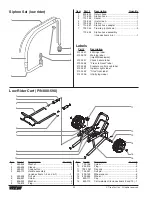

PRIME/SPRAY Valve Assembly

(P/N 800-915)

Item

Part #

Description

Quantity

1

700-823

Dowel pin ....................................................1

2

700-537

Gasket ........................................................1

3

222-012

O-ring, Teflon ..............................................1

4

221-012

O-ring, Viton................................................1

5

700-253

Valve housing .............................................1

6

800-910

Valve seat ...................................................1

7

700-697

Valve handle ...............................................1

8

700-759

Groove pin ..................................................1

9

700-721

O-ring, Viton................................................1

10

700-250

Valve stem ..................................................1

11

800-926

Spring .........................................................1

12

700-248

Valve retainer..............................................1

13

700-251

Cam base ...................................................1

1

2

3

4

5

6

7

8

9

10

11

12

13