English

English

10

© Titan Tool Inc. All rights reserved.

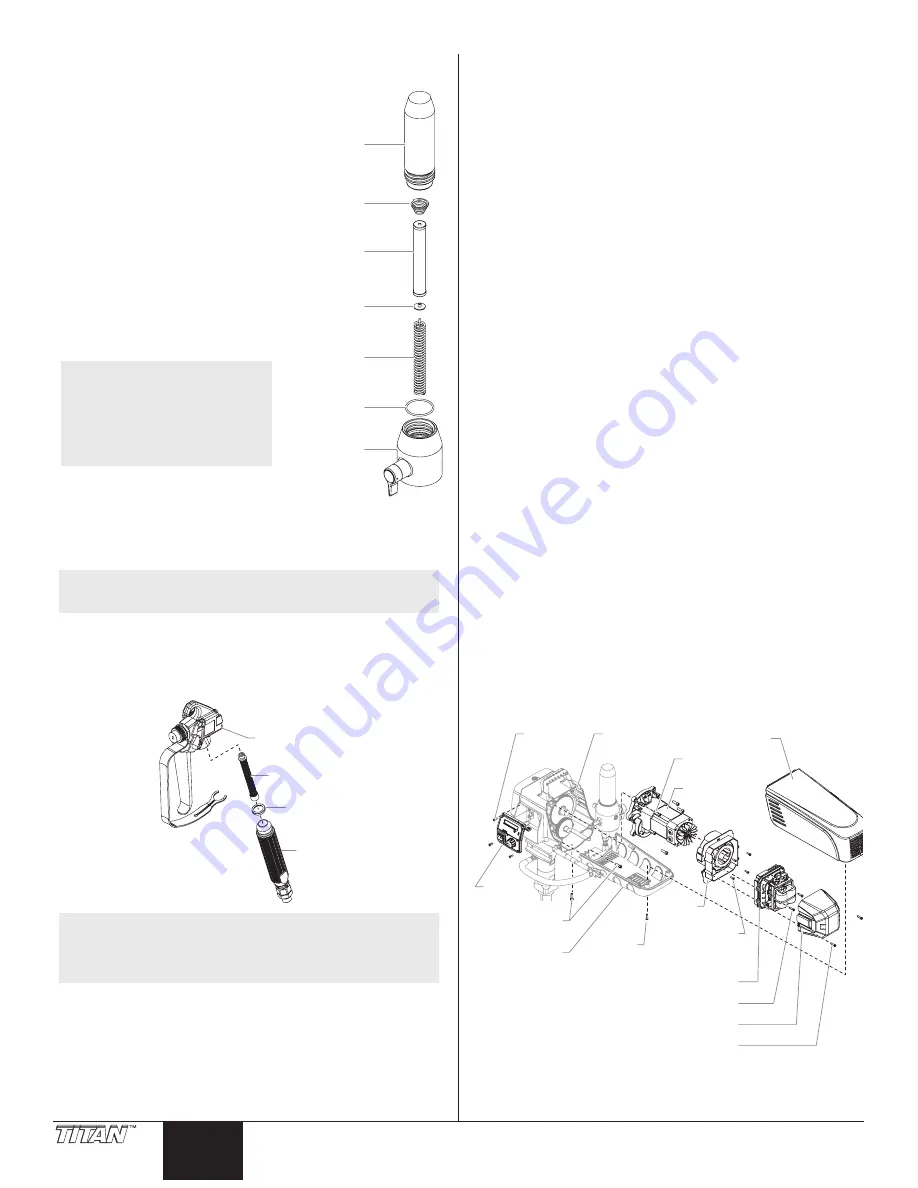

replacing the Filters

Pump Filter

Filter Body

Filter Spring

Filter Spring

Adapter

Core Spring

Filter

O-ring

Filter Housing

1. Loosen and remove the filter

body by hand.

2. Slip the filter off of the core

spring.

3. Inspect the filter. Based on

inspection, clean or replace the

filter.

4. Inspect the o-ring. Based on

inspection, clean or replace the

o-ring.

5. Slide the new or cleaned filter

over the core spring with the

filter spring adapter in place.

Push the filter into the center of

the filter housing.

6. Slide the filter body over the

filter and thread it into the filter

housing until secure.

NOTE: The filter housing

should be hand-

tightened, but make

sure the filter housing

is seated fully into the

pump block.

Gun Filter

1. Move the gun trigger lock to the unlocked position.

2. Loosen and remove the handle from the gun body.

3. Turning clockwise, unscrew the filter from the gun body.

NOTE: Left-handed threads require turning the filter

clockwise to remove.

4. Turning counterclockwise, screw the new or cleaned filter into

the gun body.

5. Make sure the handle seal is in position and thread the handle

into the gun body until secure.

6. Move the gun trigger lock to the locked position.

Handle

Handle

Seal

Filter

Gun

Body

NOTE: For more detail, part number information, and

complete assembly drawings, please see the LX-80II

Professional airless Gun Owner’s manual (P/N 313-

2293).

replacing the motor assembly

1. Unplug the unit.

2. Loosen and remove the two (2) motor shroud screws. Remove

the motor shroud.

3. Loosen and remove the three (3) belly pan screws. Remove

the belly pan.

4. Loosen and remove the two (2) motor cover screws. Remove

the motor cover.

5. Disconnect all wires between the motor and the sprayer.

6. Loosen and remove the four (4) control panel screws. Remove

the control panel.

7. Disconnect the wires between the motor and the control

panel.

8. Loosen and remove the two (2) motor controller screws.

Remove the motor controller.

9. Loosen and remove the four (4) motor baffle screws. Remove

the motor baffle.

10. Loosen and remove the six (6) motor mounting screws.

11. Pull the motor out of the gearbox housing.

12. With the motor removed, inspect the gears in the gearbox

housing for damage or excessive wear. Replace the gears, if

necessary.

13. Install the new motor into the gearbox housing.

14. Secure the motor with the six (6) motor mounting screws.

15. Reconnect the wires between the sprayer and the new motor.

(refer to the electrical schematic in the Parts List section of this

manual).

16. Place the baffle over the end of the motor assembly. Secure

with the four (4) motor baffle screws.

17. Place motor controller back into place behind the motor

baffle. Secure with the two (2) motor controller screws.

18. Reconnect all wires between the motor and sprayer.

19. Reconnect the wires between the motor and the control

panel.

20. Replace control panel and secure with four (4) control panel

screws.

21. Place the motor cover back over the motor controller. Secure

with the two (2) motor cover screws.

22. Put the belly pan back in place and secure with the three (3)

belly pan screws.

23. Slide the motor shroud over the motor assembly.

24. Secure the motor shroud with the two (2) motor shroud

screws.

Motor Shroud

Motor

Shroud

Screw

Belly Pan

Screw

Belly Pan

Motor Cover

Motor Cover Screw

Motor Controller Screw

Motor Controller

Motor Baffle

Screw

Motor

Baffle

Motor Mounting

Screw

Gearbox

housing

Control

Panel

Control

Panel

Screw

Motor