English

English

10

© Titan Tool Inc. All rights reserved.

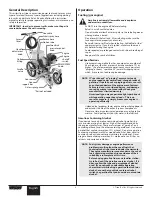

cleaning/Replacing the Gun Filter

The gun filter must be cleaned after every use of the sprayer. When

using thicker spray materials, the filter might need to be cleaned

more often.

1. Perform Pressure Relief Procedure in the Operation section of

this manual.

2. Unscrew the fitting from the bottom of the spray gun using an

adjustable wrench, making sure not to lose the spring.

3. Remove the filter from the spray gun housing and clean with

the appropriate cleaning solution (warm, soapy water for latex

paints, mineral spirits for oil-based materials).

4. Inspect the filter for holes. Replace if holes are found.

Filter

Spring

Fitting

Tapered

end

(filter top)

Hole

NOTE: Never poke the filter with a sharp instrument!

5. Replace the cleaned filter, tapered end first, into the gun

housing. The tapered end of the filter must be loaded

properly into the gun. Improper assembly will result in a

plugged tip or no flow from the gun.

6. Reassemble the spray gun.

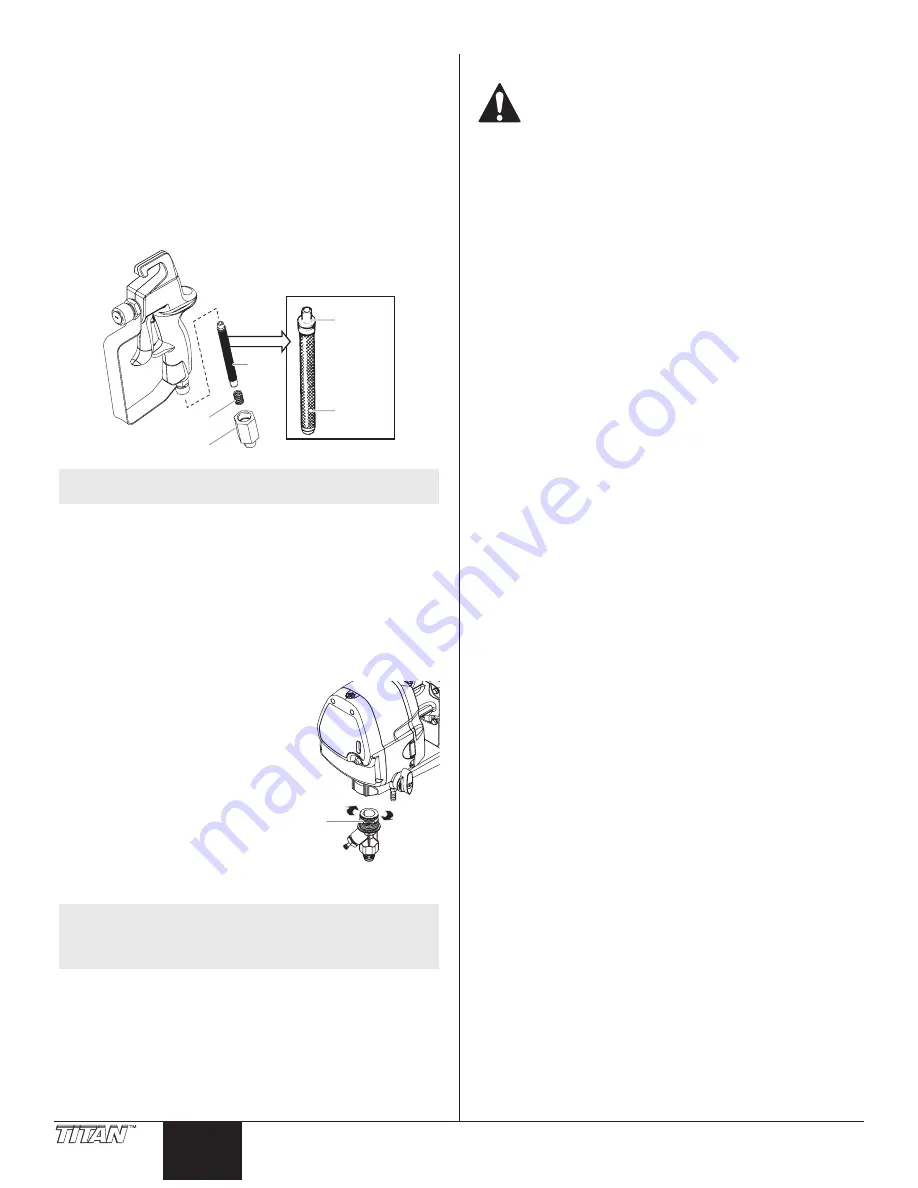

cleaning the Sureflo™ valve Assembly

Cleaning or servicing the Sureflo Valve may be required if the unit has

priming problems.

1. Remove the siphon tube.

Sureflo

valve

2. Unscrew the inlet valve

assembly from the sprayer.

Visually inspect the inside and

outside of the Sureflo Valve

assembly. Clean any paint

residue with the appropriate

cleaning solution.

3. Lubricate the o-ring on the

Sureflo Valve with petroleum

jelly. Replace Sureflo valve

assembly by threading it into

the sprayer. Torque to 32–38

ft./lbs.

4. Replace the siphon tube and

tighten securely.

NOTE: If priming problems continue, you may need to

replace the Sureflo valve. contact Technical Service

to order a new Sureflo valve assembly.

maintenance

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce the

risk of an injection injury, injury from moving parts, or

electric shock.

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

flat-blade screwdriver

T20 Torx head driver

needle-nose pliers

adjustable wrench

1. Before repairing any part of the sprayer, read the instructions

carefully, including all warnings.

ImPORTANT: Never pull on a wire to disconnect it. Pulling on a

wire could loosen the connector from the wire.

2. Test your repair before regular operation of the sprayer to be

sure that the problem is corrected. If the sprayer does not

operate properly, review the repair procedure to determine if

everything was done correctly. Refer to the Troubleshooting

section to help identify other possible problems.

3. Make certain that the service area is well ventilated in case

solvents are used during cleaning. Always wear protective

eyewear while servicing. Additional protective equipment

may be required depending on the type of cleaning solvent.

Always contact the supplier of solvents for recommendations.

4. If you have any further questions concerning your TITAN

Airless Sprayer, call TITAN:

Technical Service (U.S.) ...................................... 1-800-526-5362

Fax

................................................................. 1-800-528-4826