© Titan Tool Inc. All rights reserved.

9

English

cleaning the Spray Tip

1. Flush the gun with solvent immediately after the work is

completed.

2. Oil the sliding pins to prevent them from seizing up.

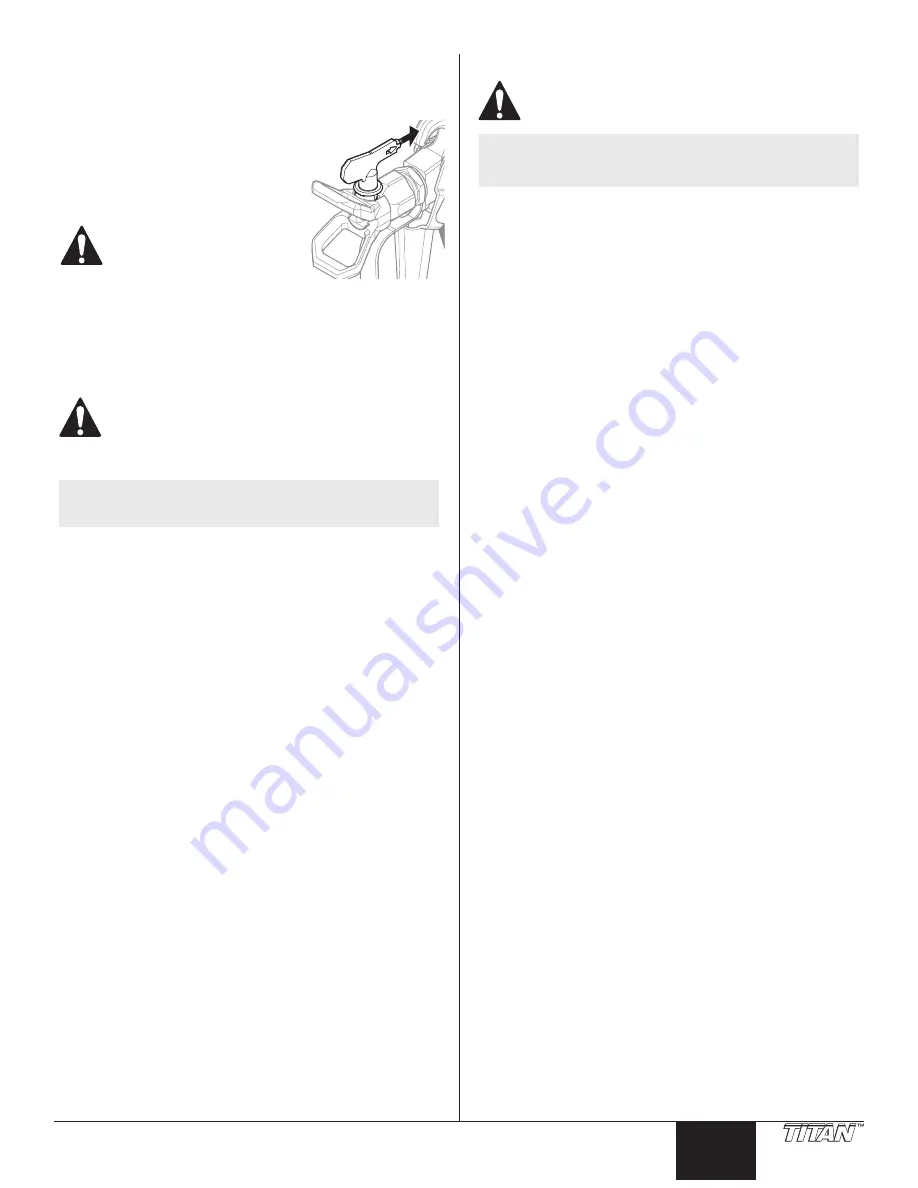

Should the spray tip become clogged,

reverse the spray tip with the lever and pull

the trigger. Once the obstruction comes out

of the spray tip, release the trigger, reverse

the spray tip back to the spray pattern

setting, and resume spraying.

Do not attempt to clean the tip

with your finger.

Do not use a needle or other

sharp pointed instrument

to clean the tip. The hard

tungsten carbide is brittle and

can be chipped.

maintenance

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce the

risk of an injection injury, injury from moving parts or

electric shock.

NOTE: All Honda engine work should be performed by a

Honda authorized service center.

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

Phillips screwdriver

3/8” hex wrench

needle-nose pliers

5/16” hex wrench

adjustable wrench

1/4” hex wrench

rubber mallet

3/16” hex wrench

flat-blade screwdriver

1/8” hex wrench

1/2” open-end wrench

7/8” open-end wrench

1. Before repairing any part of the sprayer, read the instructions

carefully, including all warnings.

ImPORTANT: Never pull on a wire to disconnect it. Pulling on a

wire could loosen the connector from the wire.

2. Test your repair before regular operation of the sprayer to be

sure that the problem is corrected. If the sprayer does not

operate properly, review the repair procedure to determine if

everything was done correctly. Refer to the Troubleshooting

section to help identify other possible problems.

3. Make certain that the service area is well ventilated in case

solvents are used during cleaning. Always wear protective

eyewear while servicing. Additional protective equipment

may be required depending on the type of cleaning solvent.

Always contact the supplier of solvents for recommendations.

4. If you have any further questions concerning your Titan airless

sprayer, call Titan:

Technical Service (U.S.) ...................................... 1-800-526-5362

Fax

................................................................. 1-800-528-4826

maintaining the Engine

When transporting a sprayer with a gas engine, make

sure the fuel is shut off.

NOTE: For detailed engine specifications and maintenance,

refer to the separate engine manual supplied with

this sprayer.

Important Facts concerning this Sprayer

This gas-powered sprayer contains a clutch that engages when

the sprayer is pumping. The sprayer’s pressure control system

engages and disengages the clutch to control pressure. To prevent

unnecessary wear to the clutch, it is advisable to adjust the engine

speed and pressure setting to limit the amount of times the clutch

engages and disengages. To reduce clutch wear, refer to the

following examples.

Example:

Operating one gun with a .019” tip — reduce the engine speed

by adjusting the throttle to a low or medium setting and increase

pressure only until the heavy ends of the spray pattern have been

eliminated.

Example:

Operating one gun with .025” tip — increase engine speed to a

higher setting and increase pressure until the heavy ends of the spray

pattern have been eliminated.

Example:

Spraying light-bodied materials at low pressure — to reduce surging

at the gun and to decrease clutch wear, reduce the engine speed to

idle and reduce pressure until the desired spray pattern is achieved.

Routine Engine maintenance

Daily

• Check and fill the gas tank.

• After the first 20 hours of operation (or 1 month), drain the oil

and refill with clean oil. Check the engine oil level and fill as

necessary.

Weekly

• Remove the cover of the air filter and clean the element.

Replace the element if necessary. If operating in an unusually

dusty environment, check the filter daily and replace if

necessary. (Replacement elements can be purchased from

your local Titan dealer.)

• After each 50 hours (or 3 months) of operation: Change the

engine oil.

Spark Plug

• Use only a (NKG) BPR6ES plug.

• Gap the plug 0.028” – 0.031” (0.7 - 0.8 mm)

• Make sure to use a spark plug wrench when installing and

removing the plug.