PowrCoat

19

GB

Servicing

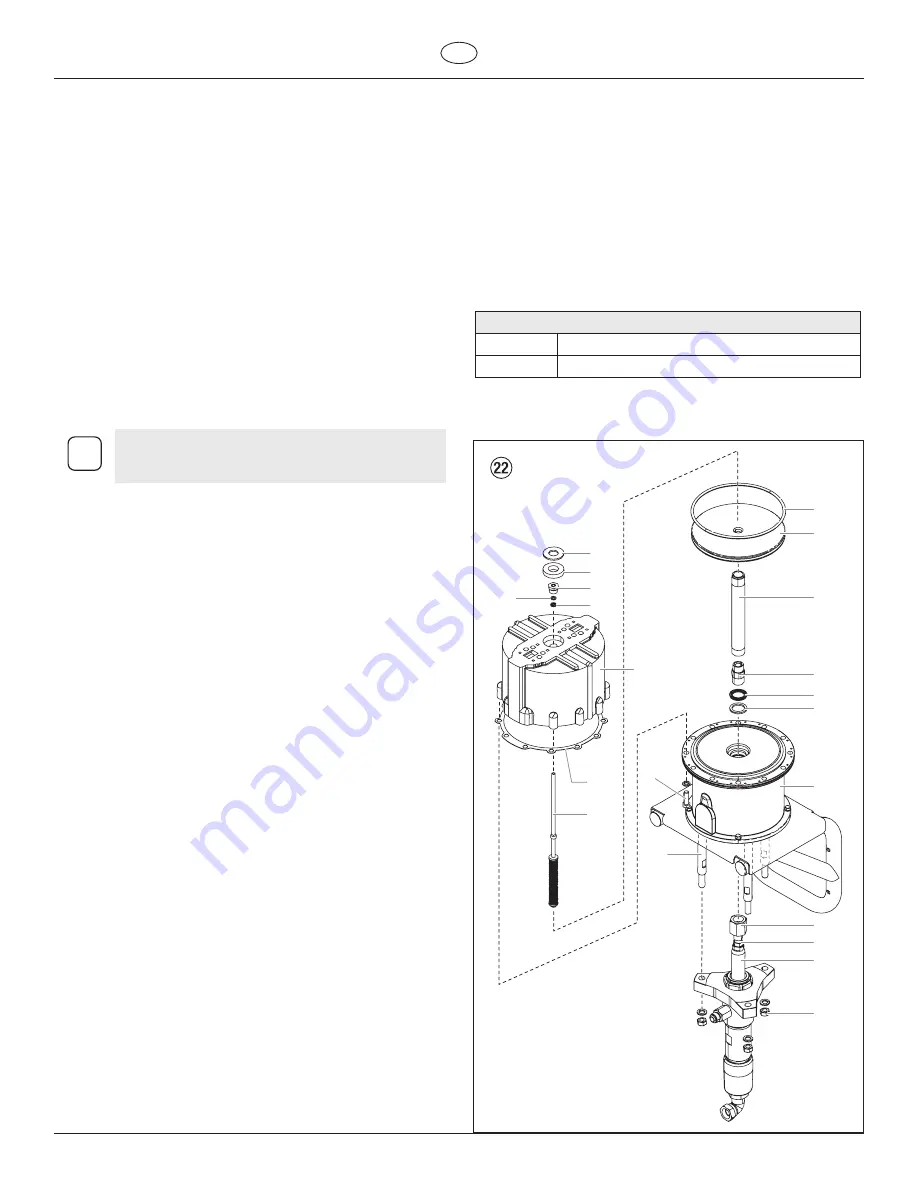

11. Remove the flat washer (Fig. 22, item 1) and rubber pad (2).

12. Using a socket, remove the bearing (3) from the cylinder.

Remove the washer (4) and packing (5).

13. Loosen and remove the screws (6) that secure the cylinder (7)

to the motor base (8). Carefully remove the cylinder.

14. With piston (10) in down position, place wrench on flats

of piston rod (9) and disconnect piston rod from pump

connecting rod (11) by unthreading the coupling nut (12). The

connecting rod (11) can remain secured to the fluid section

displacement rod (13).

15. Remove the lower stanchion nuts (14) and carefully separate

the fluid pump from the air motor assembly.

16. Remove piston rod (9) and piston (10) from motor base (8). Be

careful not to damage the piston O-ring (15).

17. Place the flats of the piston stud (16) that is still attached to

the piston rod in a vise. Place a wrench on the flats of the

piston rod (9). Loosen the piston rod from the piston stud.

18. Remove the trip rod (17) from the piston rod (9). Inspect the

trip rod for nicks or damage. A damaged trip rod cannot be

repaired and must be replaced.

19. Remove the packing (18) and the washer (19).

i

During reassembly, use all of the repair parts

included with the kit. Replace other parts as

necessary.

20. Check the surface of the piston, piston rod, and cylinder

wall for scratches or wear. A damaged piston rod will cause

excessive wear on the packings and subsequent leakage.

Reassembly Procedure (Fig. 22)

Wash all replaceable parts thoroughly with kerosene and lubricate

with Lubri-Plate or similar non-water soluble grease. For routine

servicing, use new parts from the Air Motor Service Major (see next

column for part numbers). Inspect all other parts for abnormal wear

or damage and replace if necessary.

1. Install new washer (19) and packing (18) into motor base (8).

2. Place trip rod (17) into the piston rod (9).

3. Place a wrench on the flats of the piston rod (9). Thread the

piston stud (16) into the piston rod. Torque to 456 - 504 ft.-lbs.

4. Install new piston O-ring (15) into piston (10).

5. Place new gasket (20) into position in motor base (8).

6. Place piston assembly (9, 10) into motor base (8). Do not

damage O-ring (15).

7. Replace the packing (5) washer (4) and bearing (3) onto the

cylinder. Using a socket, tighten the bearing.

8. Carefully lower the cylinder (7) onto the motor base (8). The

top of the trip rod (17) should be exposed through the hole in

the top.

9. Secure the cylinder with the cylinder screws (6).

10. Replace the rubber pad (2) and the washer (1).

11. Place wrench on the flats of the piston rod (9) and connect

pump connecting rod (13) by tightening the coupling nut (12).

12. Slide the fluid pump assembly back onto the stanchions (21)

and secure with the stanchion nuts (14).

Figure 21 -

13. Make sure the manifold gaskets (10) are in place on top of the

cylinder. Replace the manifold assemblies (Fig. 21, item 9)

back onto the cylinder and secure with the screws (8).

14. Reinstall the hub (7), spring (4), O-ring (3) and spring (2) back

into the slide valve housing (1).

15. Place slide valve housing (1) onto trip rod (5) at the same 90º

angle in figure 21.

16. Using pliers, carefully grip the trip rod being careful not to

damage the surface of the rod. Hold the rod in place. Replace

the trip rod nut (6) onto the trip rod and tighten using an

adjustable wrench.

17. Turn the slide valve housing 90º so that it drops down flush to

the clyinder.

Figure 20 -

18. Replace the washer (10) and rubber pad (9) on top of the trip

rod nut.

19. Replace the axle and roller (8) assemblies into the detent

housing (5).

20. Place the detent housing assembly (5) onto the cylinder (7).

Secure with the screws (6).

21. Replace all components (2-4) into the detent housing (5).

Secure with the spring retainers (1).

22. Reattach the outer plates by reversing steps 1-5 in "Accessing

the Air Motor", previous page.

*Service Kit

1000 Series Description

0533935

Air motor service kit

1

2

3

5*

7

17

8

10

15*

11

13

14

12

9

16

18*

19*

20*

6

4*

21