24

maintenance

PowrBeast

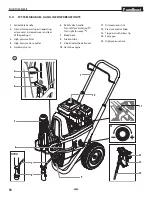

chANgINg The hyDrAulIc fluID

i

Change the hydraulic fluid every twelve months.

In order to properly change the fluid, the motor/

engine assembly must be removed. Follow the

steps below:

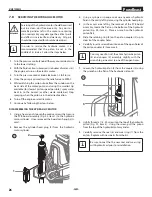

1. Put a small container (enough to hold 6.25 quarts) directly

underneath the hydraulic tank drain plug.

2. using a wrench, remove the drain plug from the hydraulic

tank. Allow the hydraulic fluid to fully drain from the tank.

Replace the drain plug.

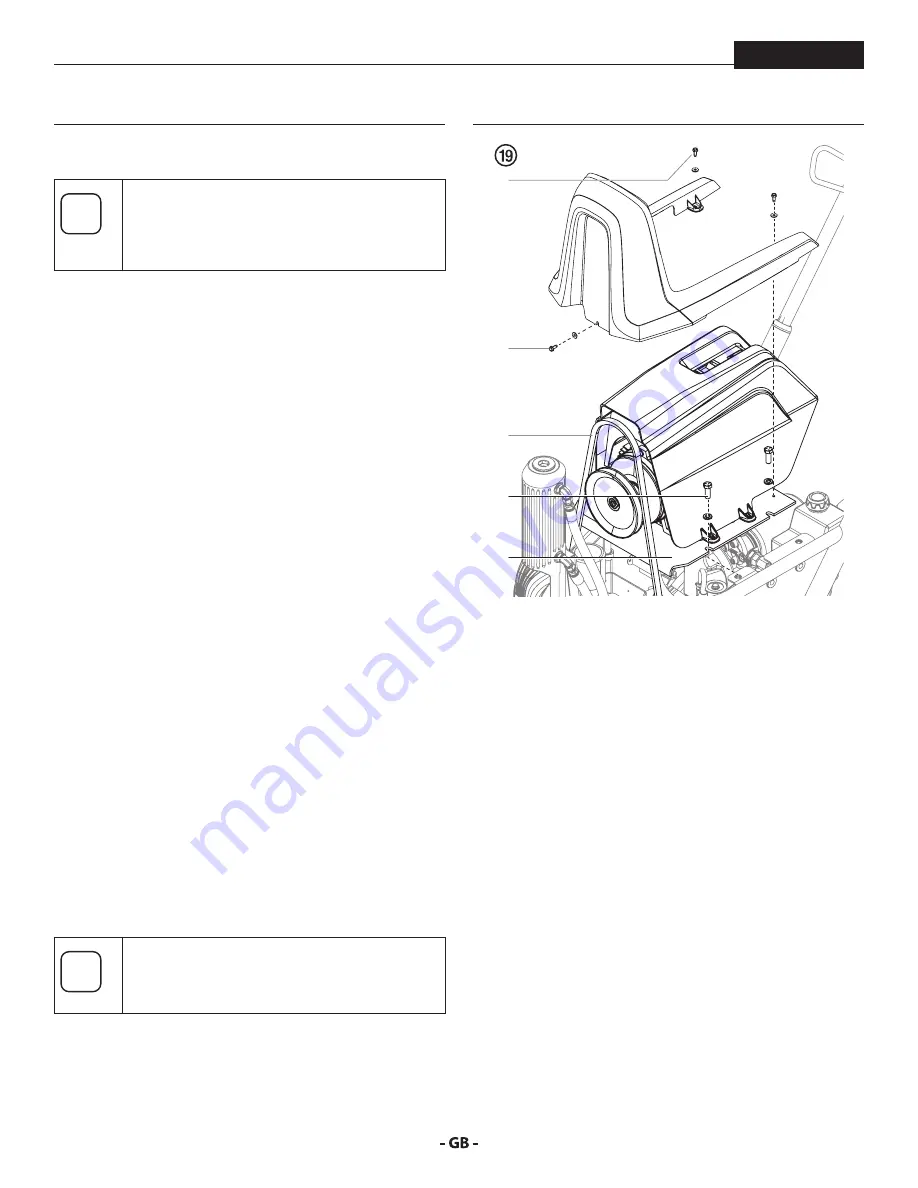

3. Remove the two screws (Fig. 19, item 1) and washers

located at the rear of the front shroud. Loosen the screw

and washer (2) located at the front of the front shroud.

Remove the front shroud.

4. The motor/engine belt (3) will now be exposed. Remove

the motor/engine belt from the top pulley.

5. Loosen and remove the four motor plate bolts and washers

(4) that secure the motor/engine assembly to the frame.

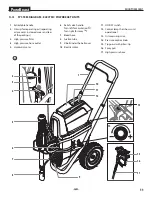

6. Gently lift the motor plate (with motor/engine still

attached) approximately 2-3 inches, and slide it over to

the left side (as looking at the rear of the unit) to expose

the breather plug (1/4” NPT) on top of the hydraulic tank.

Rest the motor plate on the frame for the next step.

7. unthread the breather plug from the hydraulic tank.

8. Fill the hydraulic tank with new hydraulic oil until the oil

touches the bottom 1/8” (3 mm) of the dipstick.

9. Apply PTFE tape to the 1/4” NPT breather plug and reinstall

to the tank.

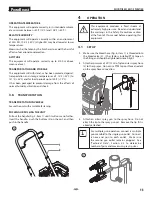

10. Slide the motor plate back into place, being careful not to

pinch or catch the PCB wire. Secure into place with the

four bolts. Torque the bolts to 250 in.lbs.

11. Replace the lower shroud and the front shroud.

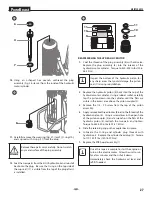

12. Start the sprayer at just enough pressure to operate the

fluid section. Run the sprayer at this low pressure for at

least 5 minutes. This removes air from the system. Check

the fluid level after this procedure. Do not over-fill.

i

When replacing the hydraulic filter (fig. 18, item

3) during a fluid change, it may be necessary to

add up to one additional quart of hydraulic fluid.

13. The hydraulic system has an external, replaceable hydraulic

filter. Change the filter every twelve months.

14. The hydraulic pump should not be serviced in the field.

If service on the hydraulic pump is required, it must be

returned to an authorized Titan Service Center.

1

2

3

4

5

7.5

mAINTAININg The fluID SecTIoN

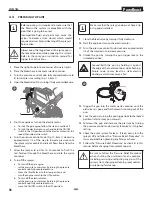

If the sprayer is going to be out of service for an extended period

of time, it is recommended that following cleanup, a kerosene

and oil mixture be introduced as a preservative. Packings may

tend to dry out from lack of use. This is particularly true of the

upper packing set for which upper packing lubricant Piston

Lube (P/N 314-480) is recommended in normal usage.

If the sprayer has been out of service for an extended period

of time, it may be necessary to prime the pump with solvent.

It is extremely important that the threads on the siphon hose

coupling are properly sealed. Any air leakage will produce

erratic operation of the sprayer and may damage the system.

The up and the down strokes should be approximately equal

in time (one should not be faster than the other). A fast up or

down stroke may indicate air in the system or malfunctioning

valve or seats (see the Troubleshooting section).