25

maintenance

PowrBeast

7.6

hIgh-preSSure hoSe

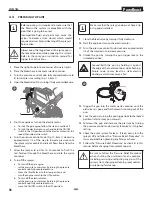

Inspect the high-pressure hose visually for any notches or

bulges, in particular at the transition in the fittings. It must be

possible to turn the union nuts freely. A conductivity of less

than 1 MΩ must exist across the entire length.

Attention

Have all the electric tests carried by an Authorized

Titan Service Center.

i

The risk of damage rises with the age of the high-

pressure hose.

Titan recommends replacing high-pressure

hoses after 6 years.

7.7

BASIc eNgINe mAINTeNANce (gAS eNgINe)

•

For detailed engine maintenance and technical

specifications refer to the separate gasoline engine manual.

•

All service to the engine should be performed by a dealer

authorized by the engine manufacturer.

•

use a premium quality motor oil. 10W30 is recommended

for general all temperature use. Other viscosities may be

required in other climates.

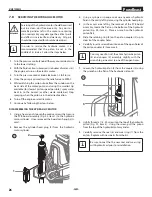

• Use only a (NGK) BP6ES or BPR6E spark plug. Gap the

plug to 0.028 to 0.031 In. (0.7 to 0.8 mm) Always use a

spark plug wrench.

DAIly

1. Check engine oil level, and fill as necessary.

2. Check gasoline level, and fill as necessary.

Always follow the fueling procedure outlined

earlier in this manual.

fIrST 20 hourS

•

Change engine oil.

eVery 100 hourS

•

Change engine oil.

•

Clean the sediment cup.

•

Clean and re-gap the spark plug.

•

Clean the spark arrestor.

Weekly

•

Remove the air filter cover and clean the element. In

very dusty environments, check the filter daily. Replace

the element as needed. Replacement elements can be

purchased from your local engine manufacturer dealer.

eNgINe operATIoN AND SerVIce

•

Clean and oil air filter pad on gasoline engine every 25

hours or once weekly. Do not permit the air intake screen

around the fly wheel of the gas engine to load up with paint

or trash. Clean it regularly. The service life and efficiency

of the gas engine model depends upon keeping the

gasoline engine running properly. Change the oil in the

engine every 100 hours. Failure to observe this may result

in engine overheating. Consult the engine manufacturer’s

service manual provided.

•

To conserve fuel, service life, and efficiency of the sprayer,

always operate the gasoline engine at the lowest RPM at

which it runs smoothly without laboring and delivers the

amount required for the particular painting operation.

Higher RPM does not produce higher working pressure.

The gasoline engine is connected to the hydraulic pump

by a pulley combination designed to produce full paint

delivery at maximum RPM.

•

The warranty on gasoline engines or electric motors is

limited to the original manufacturer.