Spraying

POSSIBLE INJECTION HAZARD. Do not spray

without the tip guard in place. Never trigger the

gun unless the tip is in either the spray or the

unclog position. Always engage the gun trigger

lock before removing, replacing, or cleaning tip.

Spraying Technique

The following techniques, if followed, will assure professional

painting results.

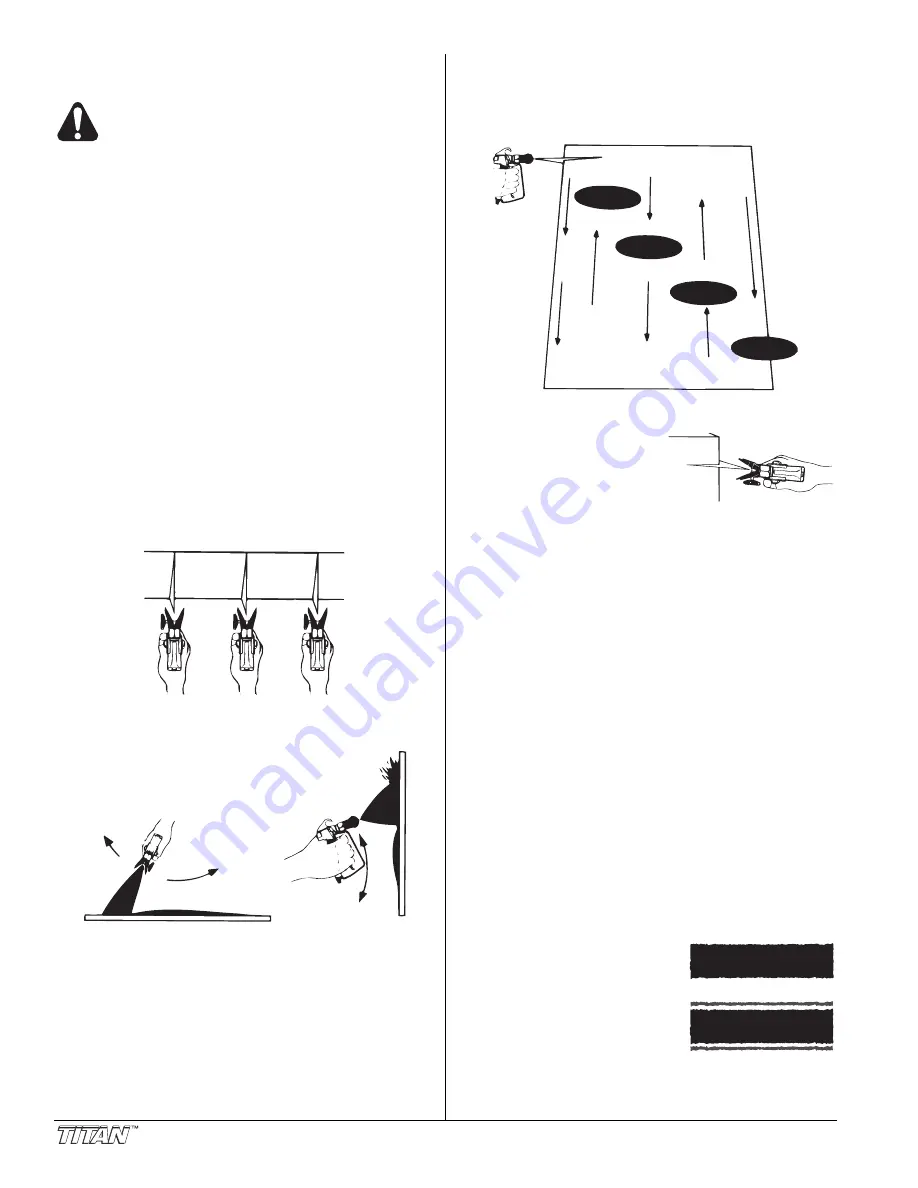

Hold the gun perpendicular to the surface and always at equal

distance from the surface. Depending on the type of material,

surface, or desired spray pattern, the gun should be held at a

distance of 12 to 14 inches (30 to 35 cm).

Move the gun either across or up and down the surface at a

steady rate. Moving the gun at a consistent speed conserves

material and provides even coverage. The correct spraying speed

allows a full, wet coat of paint to be applied without runs or sags.

Holding the gun closer to the surface deposits more paint on

the surface and produces a narrower spray pattern. Holding

the gun farther from the surface produces a thinner coat and

wider spray pattern. If runs, sags, or excessive paint occur,

change to a spray tip with a smaller orifice. If there is an

insufficient amount of paint on the surface or you desire to

spray faster, a larger orifice tip should be selected.

Maintain uniform spray stroke action. Spray alternately from

left to right and right to left. Begin movement of the gun before

the trigger is pulled.

Avoid arcing or holding the gun at an angle. This will result in

an uneven finish.

Too Thick

Offspray

Arcing

Gun at angle

start

stroke

release

trigger

pull

trigger

end

stroke

8

© Titan Tool Inc. All rights reserved.

Proper lapping (overlap of spray pattern) is essential to an

even finish. Lap each stroke. If you are spraying horizontally,

aim at the bottom edge of the preceding stroke, so as to lap

the previous pattern by 50%.

For corners and edges, split the

center of the spray pattern on the

corner or edge and spray vertically

so that both adjoining sections

receive approximately even

amounts of paint.

When spraying with a shield, hold it firmly against the surface.

Angle the spray gun slightly away from the shield and toward

the surface. This will prevent paint from being forced

underneath.

Shrubs next to houses should be tied back and covered with a

canvas cloth. The cloth should be removed as soon as possible.

Titan gun extensions are extremely helpful in these situations.

Nearby objects such as automobiles, outdoor furniture, etc.

should be moved or covered whenever in the vicinity of a

spray job. Be careful of any other surrounding objects that

could be damaged by overspray.

Practice

1. Make sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

3. Set the pressure to minimum by turning the pressure

control knob to the “Min” setting in the yellow zone.

3. Move the PRIME/SPRAY valve up to its SPRAY position.

4. Turn the pressure control knob clockwise to its highest

setting in the green zone. The paint hose should stiffen

as paint begins to flow through it.

5. Unlock the gun trigger lock.

6. Trigger the spray gun to bleed air out of the hose.

7. When paint reaches the spray tip, spray a test area to

check the spray pattern.

8. Use the lowest pressure setting

necessary to get a good spray

pattern. If the pressure is set too

high, the spray pattern will be too

light. If the pressure is set too

low, tailing will appear or the paint

will spatter out in gobs rather than

in a fine spray.

Good spray pattern

Paint tailing pattern

Overlap edges

1st

pass

2nd

pass

3rd

pass

4th

pass

5th

pass