13

description of unit

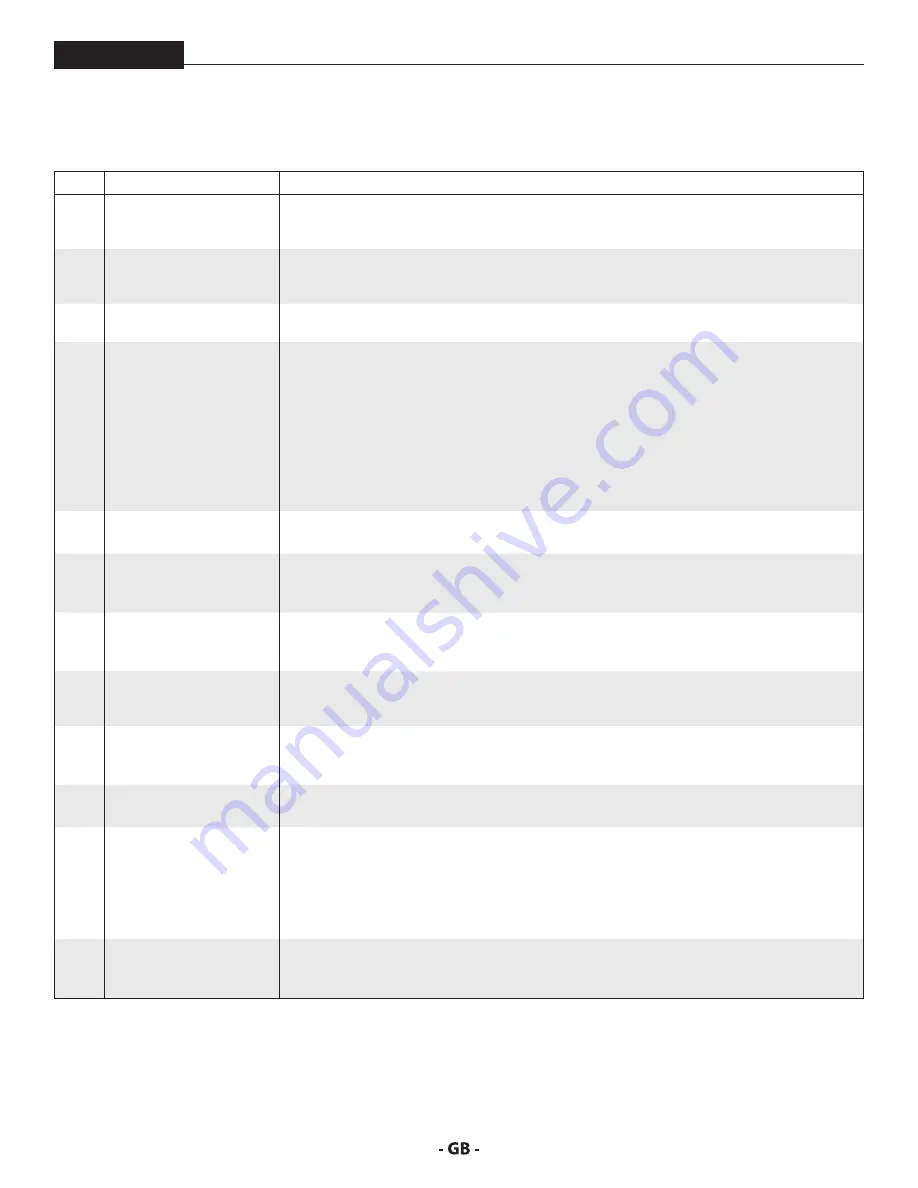

ProMark

ITem DeScrIpTIoN

fuNcTIoN

1

Dashboard

The dashboard contains the engine ignition key, the engine throttle, the pressure control knob (to

determine spraying pressure and can be used to fine-tune the spraying pattern) and the pressure

gauges for both the “A” side (spraying material” and “B” side (BPO). See section 3.4 for further details.

2

Relief valve / bleed hose

This is the relief valve for the spray material side (A) of the system. When it is open (horizontal), spray

material will circulate from the material container through the siphon hose and back to the container

through the bleed hose. When it is closed, the system will build spraying pressure.

3

BPO tank valve

The BPO valve directs the flow of BPO. When closed (horizontal), BPO is directed to the mixing chamber.

When open (vertical), BPO is circulated back into the BPO tank.

4

BPO pump adjustment

The adjustment bar contains four holes which the pump can be mounted to that changes the stroke of

the pump and subsequent ratio of BPO to spray material.

usage note:

The stroke of the BPO pump should be adjusted depending upon the environmental

conditions:

•

On colder days, the top of the pump should be mounted to one of the holes towards the inside of

the sprayer, which will increase the amount of BPO into the spraying mix.

•

On warmer days, the top of the pump should be mounted to one of the holes towards the outside

of the sprayer, which will decrease the amount of BPO into the spraying mix.

•

Each hole will increase/decrease the BPO amount by 1/2 ounce.

5

Solvent flush valve

Provides solvent to the mixing block, mixing tube and spray guns when needed.

usage note:

This valve should remain closed until the system is ready to be flushed.

6

BPO shutoff valve

The BPO shutoff valve will cut off the flow of BPO to the mixing block when closed.

usage note:

This should remain open during spraying and closed whenever performing a solvent

flush.

7

Spray material shutoff valve

The spray material shutoff valve will cut off the flow of spray material to the mixing block when closed.

usage note:

This should remain open during spraying and closed whenever performing a solvent

flush.

8

2nd gun shutoff valve (2-gun

units only)

This valve will cut off the flow of the spray mixture to the outside spray gun, allowing the user to

perform 1-gun operations. Always make sure to perform a solvent flush before shutting down one of

the spray guns.

9

Pressurized bead dispenser

regulator

This allows the user to adjust the bead dispenser pressure.

usage note:

A reading of 30-40 PSI is a recommended starting point. Follow the manufacturer’s

recommedations.

10

Solvent flush regulator

This allows the user to adjust the solvent flush pressure.

usage note:

A reading of 100 PSI is recommended whenever performing a solvent flush.

11

Hydraulic motor shutoff

valve

This valve will cut off the flow of hydraulic fluid to the hydraulic motor when closed.

usage note:

This valve should remain open when the system is running.

usage note:

To adjust the speed of the hydraulic motor (and subsequently the spraying pressure), it

is recommended that the pressure control knob on the dashboard be used for this, NOT the hydraulic

motor shutoff valve. Using the hydraulic motor shutoff valve to adjust the motor speed will put

unnecessary wear on the valve.

12

Solvent flush relief valve

This valve allows pressure to build up inside the solvent flush tank.

usage note:

Generally, this valve should remain closed even when not performing a solvent flush, as

the solvent flush valve (item 4) will be the primary delivery point of the solvent.

Summary of Contents for 200

Page 12: ...12 description of unit ProMark 3 3 System controls FIGURE 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 45: ...45 troubleshooting ProMark ...

Page 56: ...56 Gerätebeschreibung ProMark 3 3 GERÄTESTEUERUNG abb 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 89: ...89 ProMark ...

Page 100: ...100 Description du matériel ProMark 3 3 COMMANDES DU SYSTÈME fig 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 133: ...133 ProMark ...