24

system preparation

ProMark

4.6

ADJuST The Bpo TANk SeTTINg

i

The piston stroke of the pump that siphons BPO

from the BPO tank to the mixing block can be

adjusted to change the amount of BPO that is

provided to the spray mixture.

•

On colder days, the top of the pump should

be mounted to one of the holes towards the

inside of the sprayer, which will increase the

amount of BPO into the spraying mix.

•

On warmer days, the top of the pump should

be mounted to one of the holes towards the

outside of the sprayer, which will decrease

the amount of BPO into the spraying mix.

1.

To adjust, loosen and remove the bolt that secures the

pump piston to the pump arm.

2.

Replace the pump piston into the pump arm orifice that is

suitable for your spraying job.

fIgure 10

Bpo (+)

Bpo (-)

i

BPO is provided to the mixture at a 98:2 spray

material-to-BPO ratio (98 ounces spray mixture

for every 2 ounces of BPO).

For every hole that the BPO pump piston is

moved, the BPO ratio is increased or decreased

by 1/2 ounce.

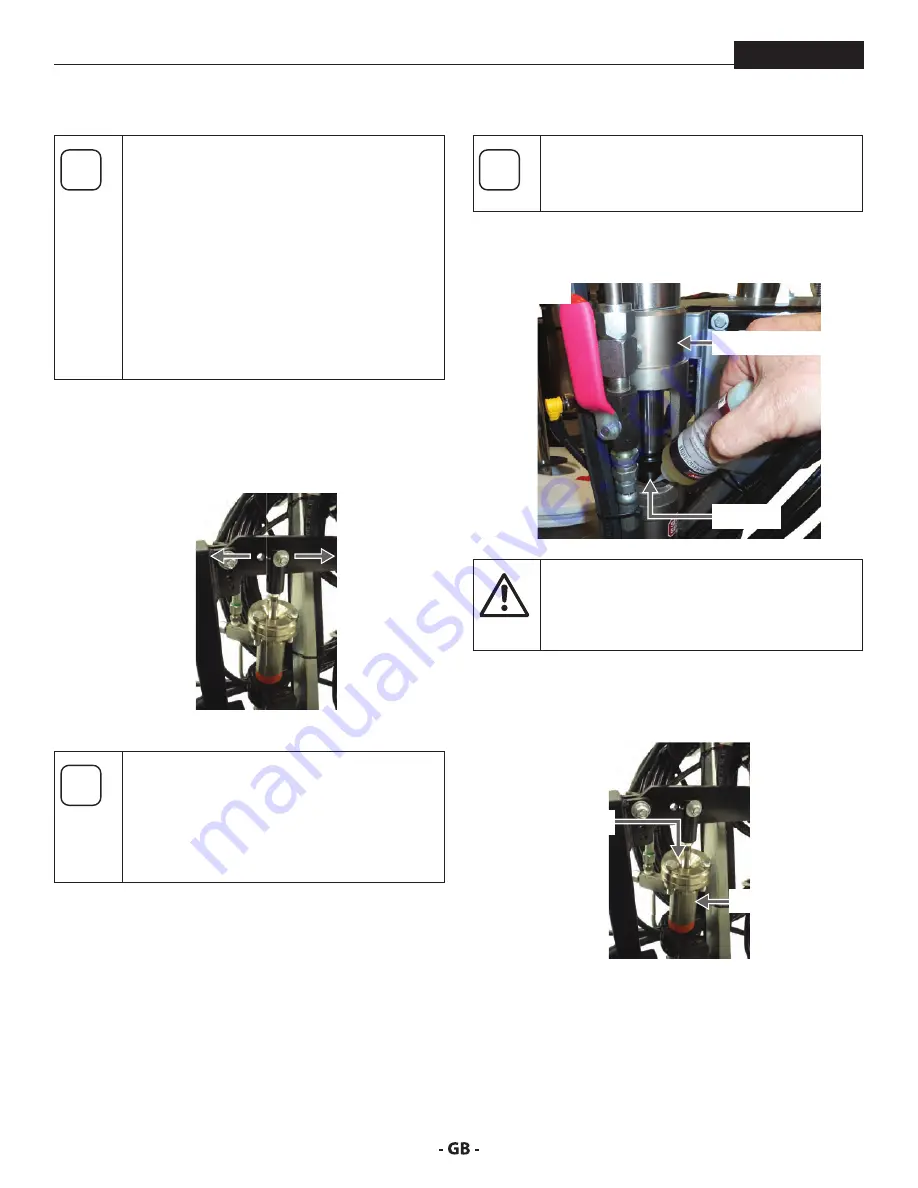

4.7

luBrIcATe The pAckINgS

i

The packings should be lubricated prior to every

use.

1.

Fill the hydraulic motor oil cup 1/2 full with Piston Lube

(P/N 314-480, included). This extends packing life.

fIgure 11A

hyDrAulIc moTor

oIl cup

Attention

Piston Lube prevents increased wear and tear to

the packings.

2.

Fill the BPO pump oil cup 1/2 full with Piston Lube (P/N

314-480, included). This extends packing life.

fIgure 11B

Bpo pump

oIl cup

Summary of Contents for 200

Page 12: ...12 description of unit ProMark 3 3 System controls FIGURE 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 45: ...45 troubleshooting ProMark ...

Page 56: ...56 Gerätebeschreibung ProMark 3 3 GERÄTESTEUERUNG abb 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 89: ...89 ProMark ...

Page 100: ...100 Description du matériel ProMark 3 3 COMMANDES DU SYSTÈME fig 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 133: ...133 ProMark ...