27

spraying

ProMark

6

SprAyINg

i

Follow the steps in this section in order to prime

the system and begin spraying.

6.1

prIme The SySTem

i

Prior to spraying, it must be verified that the BPO

and spray material are flowing freely through

their respective hoses. Follow the steps in this

section.

1.

Place a 5-gallon container of spray material onto the

hopper plate.

2.

Remove the 5-gallon container lid and replace it with the

lid that comes with the system.

3.

Insert the siphon hose through the hole in the lid and into

the spray material. Do the same with the bleed hose.

4.

Make sure all valves are in the appropriate position for

priming (refer to section 3.4 for valve locations) :

opeN

cloSeD

Hydraulic motor shutoff

Solvent flush

BPO tank / BPO shutoff

Solvent flush relief

Spray material shutoff valve

Relief valve

6.

Turn the pressure control knob on the dashboard fully

counterclockwise to its lowest pressure setting.

7.

Open the two brass clasps on either side of the BPO tank

lid and remove the lid. The tank lid can hang from its

safety cord.

8.

Make sure the BPO tank valve is in the open position. The

valve handle should be in the vertical position.

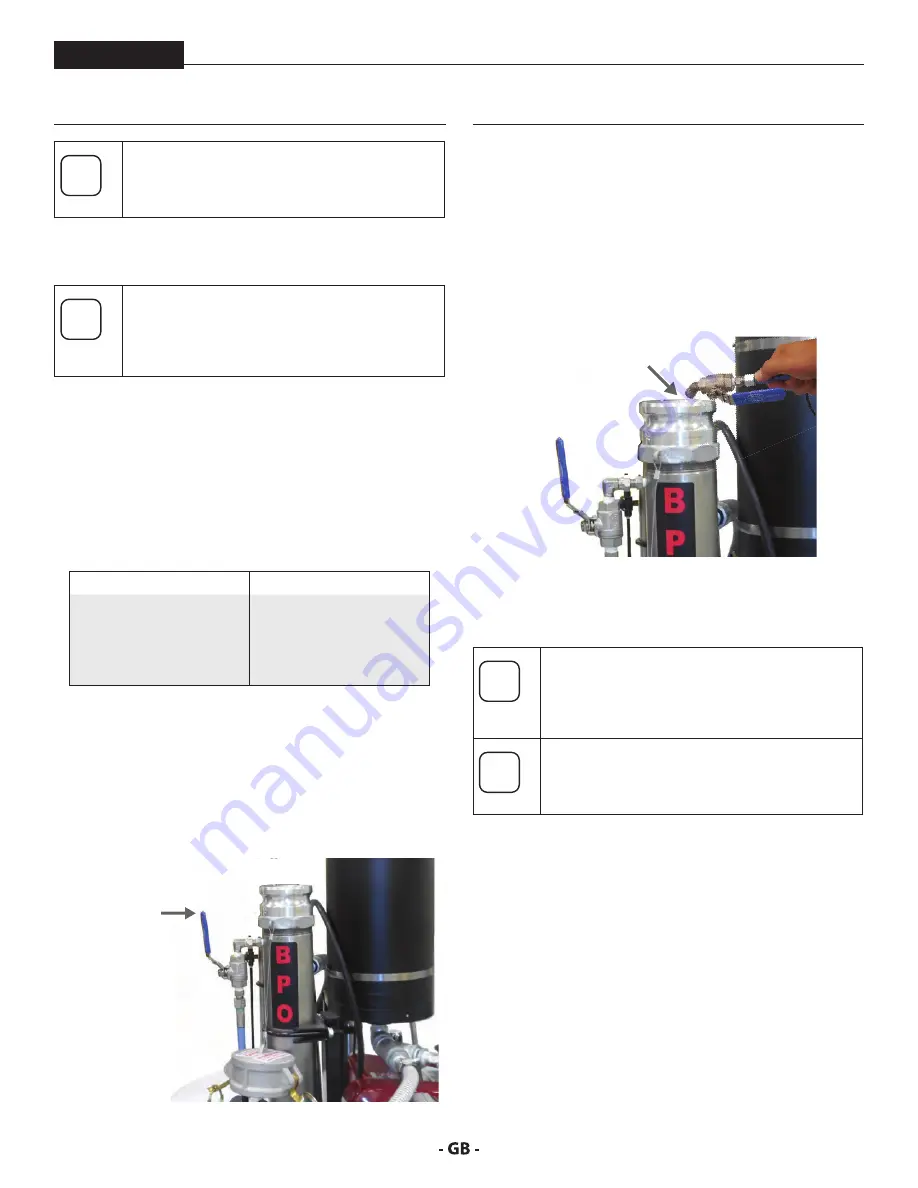

fIgure 14

Bpo TANk

VAlVe

9.

Make sure the BPO shutoff valve located near the mixing

block is in the open position. The valve handle should be

in the horizontal position.

10.

Start the engine (refer to section 5.1).

11.

While the engine is running, remove the angled fitting

that attaches the BPO hose to the mixing block with an

adjustable wrench. This is the hose marked in blue at the

top part of the mixing block.

12.

Hold the angled fitting over the BPO tank.

fIgure 15

13.

While holding the fitting over the BPO tank, close the BPO

tank valve. The valve handle should be in the horizontal

position.

i

Once the BPO tank valve is closed, BPO should

begin to flow from the end of the angled fitting.

This verifies that the BPO hose is free from

obstruction.

i

While the BPO is flowing from the angled fitting,

spray material should also be circulating from

the bleed hose back into the container.

14.

Allow the BPO to flow for 10-15 seconds back into the BPO

tank.

15.

After 10-15 seconds, open the BPO tank valve (handle in

vertical position). This should stop the flow of BPO from

the angled fitting. Allow any remaining BPO to drip out.

16.

Reconnect the angled fitting onto its place on the mixing

block. Tighten with a wrench.

Priming is now complete. The engine can keep running

and the system is ready for spraying.

Summary of Contents for 200

Page 12: ...12 description of unit ProMark 3 3 System controls FIGURE 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 45: ...45 troubleshooting ProMark ...

Page 56: ...56 Gerätebeschreibung ProMark 3 3 GERÄTESTEUERUNG abb 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 89: ...89 ProMark ...

Page 100: ...100 Description du matériel ProMark 3 3 COMMANDES DU SYSTÈME fig 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 133: ...133 ProMark ...