29

spraying

ProMark

6.4

cleANINg A cloggeD TIp

i

If the spray pattern becomes distorted or stops

completely while pulling the trigger, perform the

steps below.

Attention

This procedure must be performed quickly so

that the spray mixture does not harden and set

up inside the mixing block and mixing tube.

1.

Open the relief valve located on the high-pressure filter.

The valve handle should be in vertical position.

2.

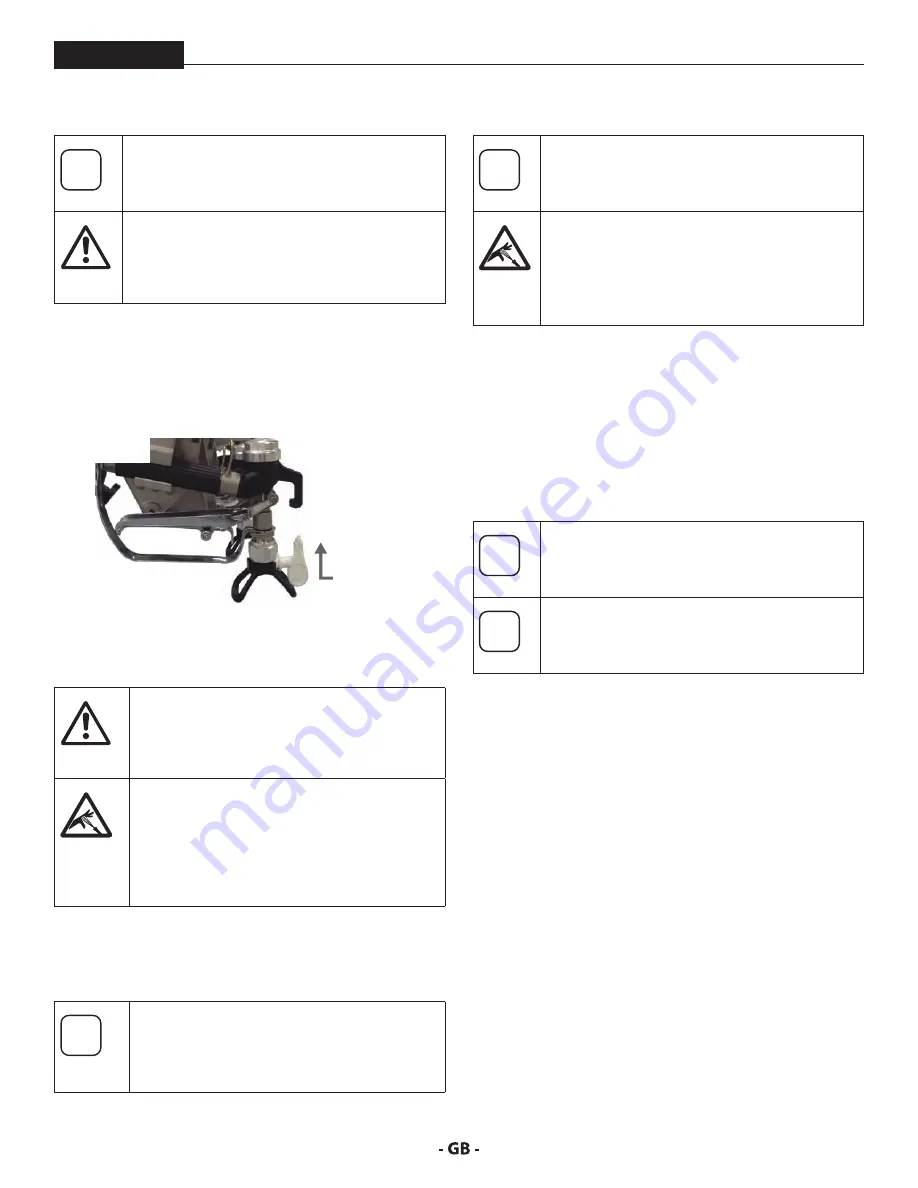

Rotate the tip handle 180° until the arrow on the handle is

facing the opposite of the spray direction and the handle

clicks in the reverse position (Fig. 16).

fIgure 16

roTATe 180º

3.

Place a waste container underneath the spray gun(s).

4.

Trigger the gun(s) once so that the pressure can blow the

clog out.

Attention

NEVER use the tip in the reverse position for

more than ONE trigger pull at a time. Rather,

this entire procedure can be repeated until the

tip is free of clogging.

The flow from the spray tip is at very high

pressure. Contact with any body part may be

dangerous. Do not place finger on gun outlet.

Do not point the gun at any person. Never

operate the spray gun without the proper tip

guard.

5.

Rotate the tip handle back to its original position.

6.

Close the relief valve handle located on the high-pressure

filter and resume spraying. Repeat this section if necessary.

i

If after performing these steps multiple times

the spray tip is still clogged, perform a full

solvent flush (section 6.3). The spray tip may

need to be replaced if clogging persists.

6.5

hANDlINg The hIgh-preSSure hoSe

i

The unit is equipped with a high-pressure hose

specially suited for airless pumps.

Danger of injury through leaking high-pressure

hose. Replace any damaged high-pressure hose

immediately.

Never repair defective high-pressure hoses

yourself!

The high-pressure hose is to be handled with care. Avoid sharp

bends and folds: the smallest bending radius is about 8” (20 cm).

Do not drive over the high-pressure hose. Protect against sharp

objects and edges.

Never pull on the high-pressure hose to move the device.

Make sure that the high-pressure hose cannot twist. This can

be avoided by using a Titan spray gun with a swivel joint and a

hose system.

i

The risk of damage rises with the age of the

high-pressure hose. Titan recommends replacing

high-pressure hoses after 6 years.

i

Use only Titan original-high-pressure hoses

in order to ensure functionality, safety and

durability.

Summary of Contents for 200

Page 12: ...12 description of unit ProMark 3 3 System controls FIGURE 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 45: ...45 troubleshooting ProMark ...

Page 56: ...56 Gerätebeschreibung ProMark 3 3 GERÄTESTEUERUNG abb 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 89: ...89 ProMark ...

Page 100: ...100 Description du matériel ProMark 3 3 COMMANDES DU SYSTÈME fig 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 133: ...133 ProMark ...