32

maintenance

ProMark

8

mAINTeNANce

Before proceeding, follow the solvent flush

procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce

the risk of an injection injury or injury from

moving parts.

8.1

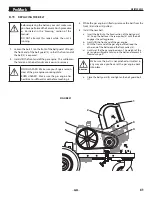

luBrIcATINg The upper pAckINgS

1.

Clean out any spray material that has seeped past the

upper packings into the oil cup reservoir above the fluid

section.

2.

Fill the packing oil reservoir 1/2 full with Piston Lube (P/N

314-480) supplied by the factory. This will extend packing

life.

fIgure 18

hyDrAulIc moTor

oIl cup

i

Do not over-fill the reservoir so that it overflows

and drips into the spray material.

8.2

mAINTAININg The fIlTer ASSemBly

i

Clean the filter regularly. Dirty or clogged filters

can greatly reduce filtering ability and cause

a number of system problems including poor

spray patterns, clogged spray tips, etc.

cleANINg (fIg. 19)

To clean the filter, perform the following procedure.

1.

Make sure a solvent flush (section 6.3) has been performed.

2.

Remove the filter cap assembly (1) and spring (2).

3.

Pull the filter element with ball straight (3) out of the filter

body (4).

4.

Clean inside the filter body, filter element with ball, and

filter cap assembly using the appropriate solvent.

1

2

3

7

8

5

6

4

fIgure 19

i

Use care in handling parts as dirt, debris,

scratches, or nicks may prevent o-rings or gaskets

from sealing.

This filter element filters from the inside out. Be

sure to clean the filter element thoroughly on the

inside. Soak in solvent to loosen hardened spray

material or replace.

Summary of Contents for 200

Page 12: ...12 description of unit ProMark 3 3 System controls FIGURE 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 45: ...45 troubleshooting ProMark ...

Page 56: ...56 Gerätebeschreibung ProMark 3 3 GERÄTESTEUERUNG abb 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 89: ...89 ProMark ...

Page 100: ...100 Description du matériel ProMark 3 3 COMMANDES DU SYSTÈME fig 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 133: ...133 ProMark ...