34

maintenance

ProMark

8.4

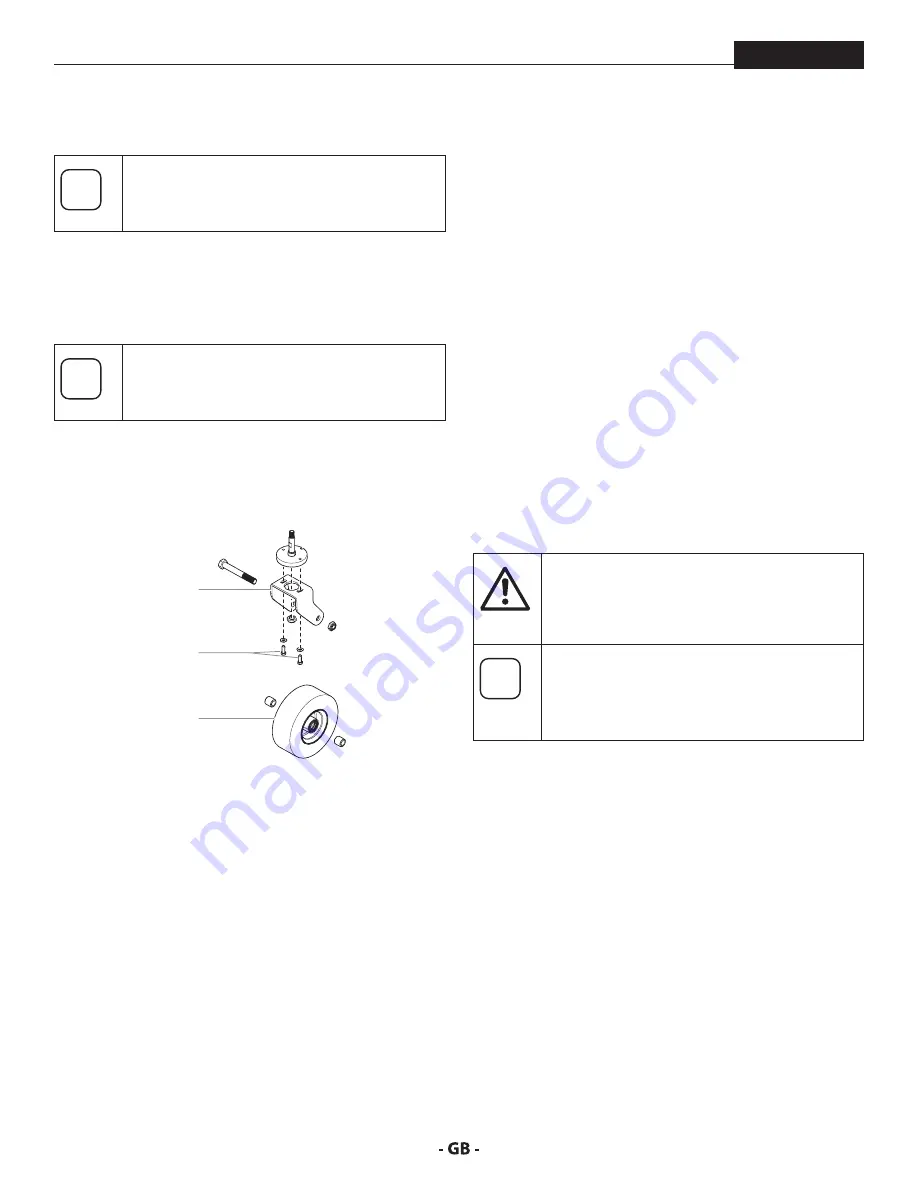

ADJuSTINg The TrAckINg of The froNT

cASTer

i

The front caster is set by the factory to track in

a straight line. Use the following procedure if

adjustment the caster becomes necessary.

1.

Loosen the two hex screws (1) in the top of the caster

mounting bracket (2).

2.

Turn the caster mounting bracket (2) slightly in the desired

direction.

i

The front caster locking pin must be engaged

during tracking adjustment.

3.

Tighten the two hex screws (1).

4.

Check the tracking of the front caster (3). If the caster does

not track straight, repeat the above procedure.

1

2

3

fIgure 21

8.5

mAINTAININg The fluID SecTIoN

If the sprayer is going to be out of service for an extended period

of time, it is recommended that following cleanup, a kerosene

and oil mixture be introduced as a preservative. Packings may

tend to dry out from lack of use. This is particularly true of the

upper packing set for which upper packing lubricant Piston

Lube (P/N 314-480) is recommended in normal usage.

If the sprayer has been out of service for an extended period

of time, it may be necessary to prime the pump with solvent.

It is extremely important that the threads on the siphon hose

coupling are properly sealed. Any air leakage will produce

erratic operation of the sprayer and may damage the system.

The up and the down strokes should be approximately equal

in time (one should not be faster than the other). A fast up or

down stroke may indicate air in the system or malfunctioning

valve or seats (see the Troubleshooting section).

8.6

hIgh-preSSure hoSe

Inspect the high-pressure hose visually for any notches or

bulges, in particular at the transition in the fittings. It must be

possible to turn the union nuts freely. A conductivity of less

than 1 MΩ must exist across the entire length.

Attention

Have all the electric tests carried by an Authorized

Titan Service Center.

i

The risk of damage rises with the age of the high-

pressure hose.

Titan recommends replacing high-pressure

hoses after 6 years.

Summary of Contents for 200

Page 12: ...12 description of unit ProMark 3 3 System controls FIGURE 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 45: ...45 troubleshooting ProMark ...

Page 56: ...56 Gerätebeschreibung ProMark 3 3 GERÄTESTEUERUNG abb 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 89: ...89 ProMark ...

Page 100: ...100 Description du matériel ProMark 3 3 COMMANDES DU SYSTÈME fig 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 133: ...133 ProMark ...