38

maintenance

ProMark

13.

Thread cylinder head (8) down onto the cylinder (29) and

then back off just enough to reassemble hydraulic fittings

and motor tube (23). Tighten lock ring with spanner

wrench to hold cylinder head in position.

14.

14. The tee assembly (24) and the elbow (22) use an o-ring

(25) to seal on the outer diameter (O.D.) of the motor tube

(23). The O.D. of the motor tube should be free of scratches

or sharp edges. The lock nuts on these fittings first should

be hand tightened, then wrench tightened another half

turn.

15.

15. Install o-ring (2) onto cylinder head plug (1). Tighten.

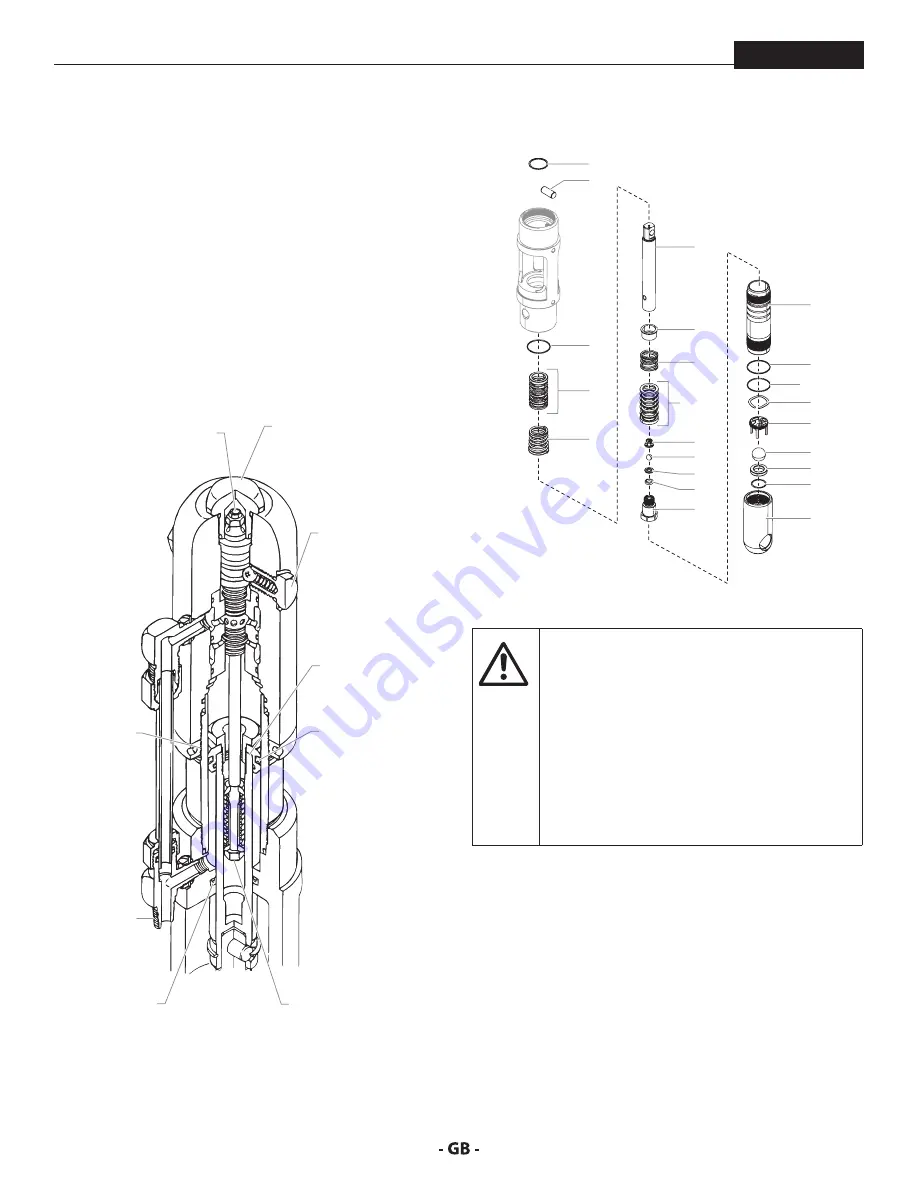

hyDrAulIc moTor cuT-AWAy

Torque flex locknut to

40 in.-lbs. (4.5 Nm).

Use blue Loctite.

Use blue

Loctite on

lock ring.

Seal lip must

face up.

Use

hydraulic

sealant.

Torque head plug to

15 ft.-lbs. (22 Nm).

Do not over-tighten

o-ring seal.

Torque trip

retainers to

8 ft.-lbs. (10.8 Nm).

Do not over-tighten

o-ring seal.

Torque piston

retainers to

40 ft.-lbs. (55 Nm).

Use red Loctite.

Seal lip must

face down.

Valve rod assembly

is factory set and

permanently Loctited.

Do not disassemble.

fIgure 24

8.9

SerVIcINg The fluID SecTIoN

6

7

8

9

13

10

11

12

14

15

16

17

18

19

20

3

21

1

2

5

4

4

3

fIgure 25

Attention

Use of non-Titan service parts may void warranty.

Ask for original parts made by Titan for best

services. This pump should receive a routine

servicing after approximately 1,000 hours of use.

Earlier servicing is required if there is excessive

leakage from the top packing or if pump strokes

become faster on one stroke or the other.

The use of Titan Piston Lube (P/N 314-480) is

recommended as an upper packing lubricant.

Do not substitute oil, water, or solvent for an

upper packing lubricant.

DISASSemBlINg The fluID SecTIoN

1.

Remove the siphon hose assembly. Unthread the foot

valve housing (21) and the pump cylinder (14) with a strap

wrench.

2.

Slide the retainer ring (1) up with a small screwdriver, then

push the connecting pin (2) out.

3.

Pull the displacement rod (6) through the lower cavity of

the motor/pump block.

4.

Remove the PTFE o-ring (3), upper packing spring (5), and

upper packing set (4) from the motor/pump block.

5.

Hold the displacement rod (6) in a vise by the flats at the

top of the displacement rod and remove the outlet valve

housing (13) with a wrench while holding the displacement

Summary of Contents for 200

Page 12: ...12 description of unit ProMark 3 3 System controls FIGURE 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 45: ...45 troubleshooting ProMark ...

Page 56: ...56 Gerätebeschreibung ProMark 3 3 GERÄTESTEUERUNG abb 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 89: ...89 ProMark ...

Page 100: ...100 Description du matériel ProMark 3 3 COMMANDES DU SYSTÈME fig 3 1 5 4 8 2 3 6 7 9 10 11 12 ...

Page 133: ...133 ProMark ...