Titan Implement, LLC

47

3515 Flex-Wing Rotary Cutter

(423) 334-0012

February 2020

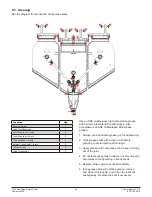

9.4 Gearbox Lubrication

The gearboxes are filled at the factory and should

require no maintenance. If there is evidence of

leakage, the grease level should be checked. If

required, grease should be added until it comes to the

proper level. Recommended lubricant is EP-0 Grease.

Splitter gearbox capacity is 58 ounces.

Outboard gearbox capacity is 49 ounces.

Note:

Make sure the rotary cutter is level when

checking the grease in the gearbox.

Note:

Overfilling the gearbox will cause pressure to

build up and cause the seals to leak.

9.5 Driveline Lubrication

Lubricate all driveline slip joints, U-joint crosses, and

the center driveline CV joint every eight operating

hours.

1. Lower the rotary cutter to the ground, disconnect the

center driveline from the tractor PTO shaft, and slide

the halves apart but do not disconnect from each

other.

2. Apply a bead of grease completely around male half

where it meets female half. Slide drive halves over

each other several times to distribute grease.

3. Disconnect the wing drivelines from the splitter

gearbox and repeat Step 2 for each wing driveline.

4. Rotate the front driveline safety shield until the holes

in the shield match up with the grease zerks in the

CV joint and U-joint.

5. Apply grease to all accessible grease zerks.

6. Rotate the driveline shield 180° until the holes on

the opposite side align with the remaining grease

zerks, and apply grease.

7. Repeat for the U-joint at the rear of the center

driveline,and at both ends of the wing drivelines.

8.

Grease the zerks on the splitter cross shaft.

9. Re-connect the drivelines, close the front gearbox

shield, and install the retaining pins.

9.6 Blade Servicing

Inspect blades before each use to determine that they

are properly installed and in good condition. If any

blade is bent, excessively nicked, worn, or has any

other damage, replace both blades on the spindle.

Small nicks can be ground out when sharpening.

Manually rock the blade carriers to check for any

looseness. Recheck torque every fifty hours.

Retighten any loose parts.

9.6.1 Blade Removal

To remove the blades for sharpening or replacement,

remove the nut and lockwasher from the blade bolt

through the inspection hole in the deck of the mower

near the gearbox.

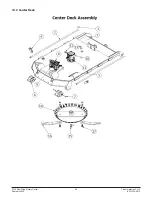

9.6.2 Blade Installation

When installing blades, be sure to check the blade bolt

pivot diameter for wear. Replace the bolt if worn more

than 1/4 inch at any point. Tighten nut to 600 ft. lbs.

Always use a new lockwasher and nut when replacing

the blade bolt.

Make sure blades are installed with the cutting edge in

the direction of rotation. The left and center spindles

rotate counterclockwise as viewed from above the

deck. The right spindle rotates clockwise as viewed

from above the deck.

Summary of Contents for 3515

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 55: ...Titan Implement LLC 55 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 59: ...Titan Implement LLC 59 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 61: ...Titan Implement LLC 61 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 63: ...Titan Implement LLC 63 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 65: ...Titan Implement LLC 65 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 76: ...3515 Flex Wing Rotary Cutter 76 Titan Implement LLC February 2020 423 334 0012 ...

Page 77: ...Titan Implement LLC 77 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...