© Titan Tool Inc. All rights reserved.

13

Pole Guns Operation

Independent controls are provided for air and fluid. Those

controls will give positive shut-off or may be used for throttling

flow for full control of spray. Accordingly, a small amount of fluid

and air permit spot application and control at roof edges and

around masked areas. Fully opened valves allow maximum

production on open areas.

NOTE: air valve (11) must be opened or closed to

activate the StediFlo™ valve. If material valve

(13) is closed and the air valve is left open, the

pump will not stop until pressure builds. The

resultant surge when the material valve is opened

will give a momentary quantity of excessive

material.

Maintenance

A faulty spray may be caused by dried material around the fluid

nozzle or the air cap. Soak in thinners to soften and remove with

brush or cloth. Never use metal objects to clean the air cap or

fluid nozzle. Should either become damaged or worn, they must

be replaced to obtain a perfect spray.

Intermittent spray may be caused by dirt between the fluid nozzle

seat and the gun head, or a loose nozzle. To correct, remove

the fluid nozzle and clean seating surfaces with thinners and refit

nozzle tightly.

Specifications

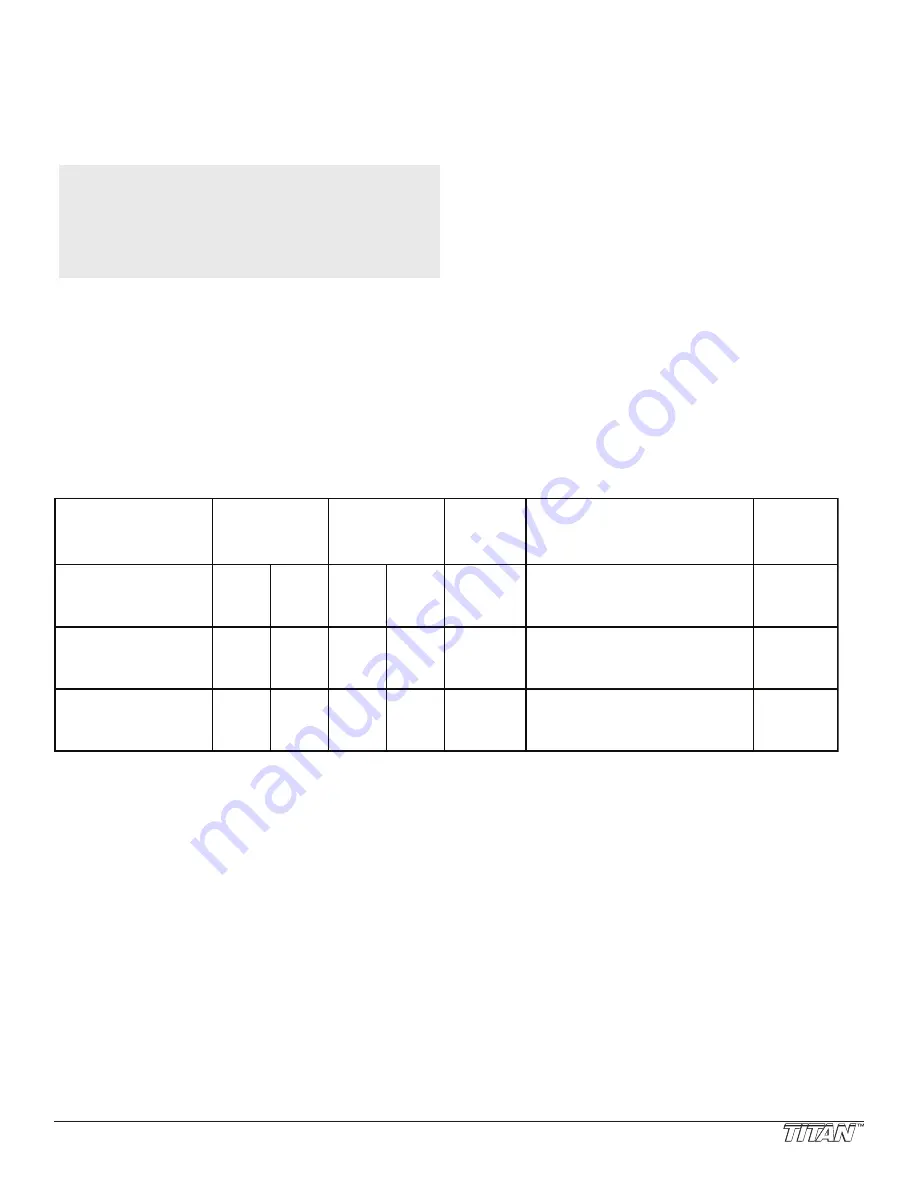

Type of work

Nominal air

consumption

cfm

1/m

psi

atm

Air

pressure

Air cap

Part No.

Fluid nozzle

Spray

Mastics, Textures,

Fibrated Coatings

Fireproofing, Ingulation

5-15

142-426

5-15

142-426

40-80

3 - 5.5

40-80

3 - 5.5

701-620

701-616

701-626 3/16”- 4.75mm

701-626 3/16”- 4.75mm

Round

Flat

As above but capable

of higher speed of

application

10-20 284-528

10-20 284-528

40-80

3 - 5.5

40-80

3 - 5.5

701-621

701-617

701-624 1/4”- 6.3mm

701-624 1/4”- 6.3mm

Round

Flat

As above but capable

of higher speed of

application

15-25 426-710

15-25 426-710

40-80

3 - 5.5

40-80

3 - 5.5

701-622

701-619

701-628 3/8”- 9.5mm

701-628 3/8”- 9.5mm

Round

Flat