2

© Titan Tool Inc. All rights reserved.

Important Safety Information

·

Read all safety information before

operating the equipment. SavE ThESE INSTRucTIONS.

English

This symbol indicates a hazardous situation, which, if not

not avoided could result in death or serious injury.

To reduce the risks of fire or explosion, electrical shock

and the injury to persons, read and understand all

instructions included in this manual. Be familiar with the

controls and proper usage of the equipment.

haZaRD: GENERaL

Can cause severe injury or property damage.

PREvENTION:

• Read all instructions and safety precautions before operating any

equipment.

• Comply with all appropriate local, state and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act (OSHA).

These standards, particularly Part 1910 of the General Standards

and Part 1926 of the Construction Standard should be consulted.

• This equipment is designed to be used with authorized parts only.

When using this equipment with parts that do not comply with

the minimum specifications and safety devices of the equipment

manufacturer, the user assumes all risks and liabilities.

• Check all hoses for cuts, leaks, abrasion or bulging of cover, as

well as damage or movement of couplings before each use. If any

of these conditions exist, replace the hose immediately. Never

repair a paint hose.

• Never aim the spray gun at any part of the body.

haZaRD: SkIN BuRN INjuRy

Heated parts can cause severe skin burn injury.

PREvENTION:

• Quick-disconnect fittings on the hose and the spray gun become

hot during use. Avoid skin contact with any quick-disconnect

fittings when they are hot. Allow the quick disconnect fittings to

cool before disconnecting the spray gun from the hose

• The compressor becomes hot during use. Allow the compressor

to cool before touching it.

haZaRD: haZaRDOuS vaPORS

Paints, solvents, insecticides, and other materials can be

harmful if inhaled or come in contact with the body. Vapors

can cause severe nausea, fainting, or poisoning.

PREvENTION:

• Use a respirator or mask whenever there is a chance that vapors

may be inhaled. Read all instructions with the mask to insure that

it will provide the necessary protection against the inhalation of

harmful vapors.

haZaRD: ExPLOSION

Compressed air has great force and may cause injury.

PREvENTION:

• The pressure pot assembly is protected from over-pressurizing

by a safety valve. Pull the ring on the safety valve occasionally

to make sure that the valve operates freely. The valve must be

replaced if it does not operate freely or if it does not release air

when the ring is pulled.

• Never modify the pressure pot or the compressor.

• Never connect other air tools to the compressor.

haZaRD: ExPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Property

damage and/or severe injury can occur.

PREvENTION:

• Exhaust and fresh air introduction must be provided

to keep the air within the spray area free from the

accumulation of flammable vapors.

• Keep the turbine at the maximum distance possible from the

spray area.

• Avoid all ignition sources such as static electricity sparks, open

flames, pilot lights, hot objects, cigarettes, and sparks caused by

connecting and disconnecting power cords and operating light

switches.

• Keep the motor away from spray area to avoid solvent and paint

fumes. Motor contains arcing parts which emit sparks.

• Fire extinguishing equipment must be present and in working

order.

• The power cord must be connected to a grounded circuit.

• Follow the material and solvent manufacturer’s safety precautions

and warnings.

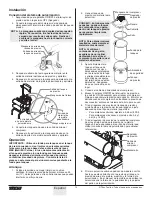

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape

wire for the electric current. This product is equipped with a cord having

a grounding wire with an appropriate grounding plug. The plug must

be plugged into an outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WaRNING - Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary,

do not connect the green grounding wire to either flat blade

terminal. The wire with insulation having a green outer

surface with or without yellow stripes is the grounding wire and must be

connected to the grounding pin.

Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as

to whether the product is properly grounded. Do not modify the plug

provided. If the plug will not fit the outlet, have the proper outlet installed

by a qualified electrician.

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

ImPORTaNT: use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the plug on

the product. make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough

to carry the current your product will draw. an undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating. a 12 gauge cord is recommended. If an extension

cord is to be used outdoors, it must be marked with the suffix

W-a after the cord type designation. For example, a designation

of SjTW-a would indicate that the cord would be appropriate for

outdoor use.

NOTE: more than 100 feet of extension cord is not

recommended. use more paint hose, not more

extension cord. Shorter extension cords will assure

maximum electrical power for proper operation.