4

© Titan Tool Inc. All rights reserved.

English

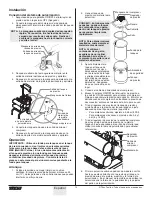

Setup

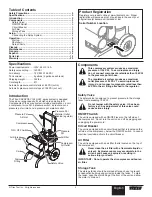

connecting the Spray System

1. Make sure the ON/OFF lever on the pressure switch is in

the OFF position.

2. Connect the compressor hose from the lower storage tank

to the pressure pot air inlet.

NOTE: The hose features quick-disconnect fittings.

To use, pull back on the spring-loaded collar

of each fitting. Slide the hose fitting over the

correct connection and release the collar.

Pressure Pot Air Inlet

Pressure Pot Air Hose

3. Thread the end of the material hose onto the pressure pot

material outlet and tighten.

4. Thread the other end of the material hose onto the spray

gun material inlet and tighten.

Pressure Pot Outlet

Material Hose

Air Hose

Spray Gun

Material

Inlet

Spray Gun

Air Inlet

5. Connect the air hose to the compressor air outlet.

6. Thread the other end of the air hose onto the spray gun air

inlet and tighten.

Operation

ImPORTaNT: use a pot liner in the pressure pot when

spraying or cleaning with hot solvents such as lacquer-

based paints, lacquer thinner, and m.E.k. The use of hot

solvents in the pressure pot without a pot liner may lift the

paint off the interior of the pressure pot and contaminate the

paint finish. Refer to the parts list in this manual for the pot

liner part number.

Startup

1. Place the unit in a clean, dry, and well-ventilated area.

The compressor should be located at least 12” from walls

or other obstructions that could interfere with the flow of

air.

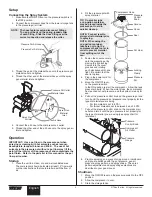

Cover

Groove

Seal

Locking

Clamp

Pressure

Pot

Compressor Hose

Pressure

Control

Knob

Pot Liner

2. Fill the pressure pot with

spray material.

TIP: On smaller jobs

a one-gallon container

may be placed inside the

pressure pot to aid in

quicker cleanup.

NOTE: For best results,

always strain material prior

to spraying.

NOTE: When using the

one-gallon container,

take care not to tip the

compressor back too far in

order to prevent material

from spilling out of the

can.

3. Fasten the cover securely

onto the pressure pot by

placing the five locking

clamps into the cover

grooves and rotating

each clockwise until hand

tight. Be certain that the

seal is in place.

4. Plug in the power cord for

the compressor.

5. Move the ON/OFF lever

on the pressure switch

to the ON position to start the compressor. Allow the tank

pressure to build. When the motor stops, the compressor

has reached cut-out pressure, and the system is ready for

use.

6. Pull out the pressure control knob on the pressure pot and

turn it until the pressure pot pressure is set properly for the

type of material you are using.

• For thin materials, set to 8 PSI.

• For thicker materials, set to between 8 and 14 PSI.

7. Pull out the pressure control knob on the compressor air

outlet and turn it until the gun pressure is set properly for

the type of material you are using.(see spray chart for

reference).

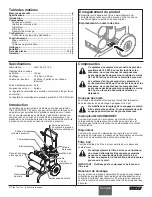

Compressor

Air Outlet

Pressure

Gauge

Pressure

Control Knob

8. Practice spraying on a piece of scrap wood or cardboard

until you are satisfied with the pot pressure, gun air

pressure, spray pattern, and spray shape. The spray

pattern adjustments and spray shape selections are

described in your gun manual.

Shutdown

1. Move the ON/OFF lever on the pressure switch to the OFF

position.

2. Allow the compressor to cool.

3. Drain the storage tanks.