© Titan Tool Inc. All rights reserved.

5

English

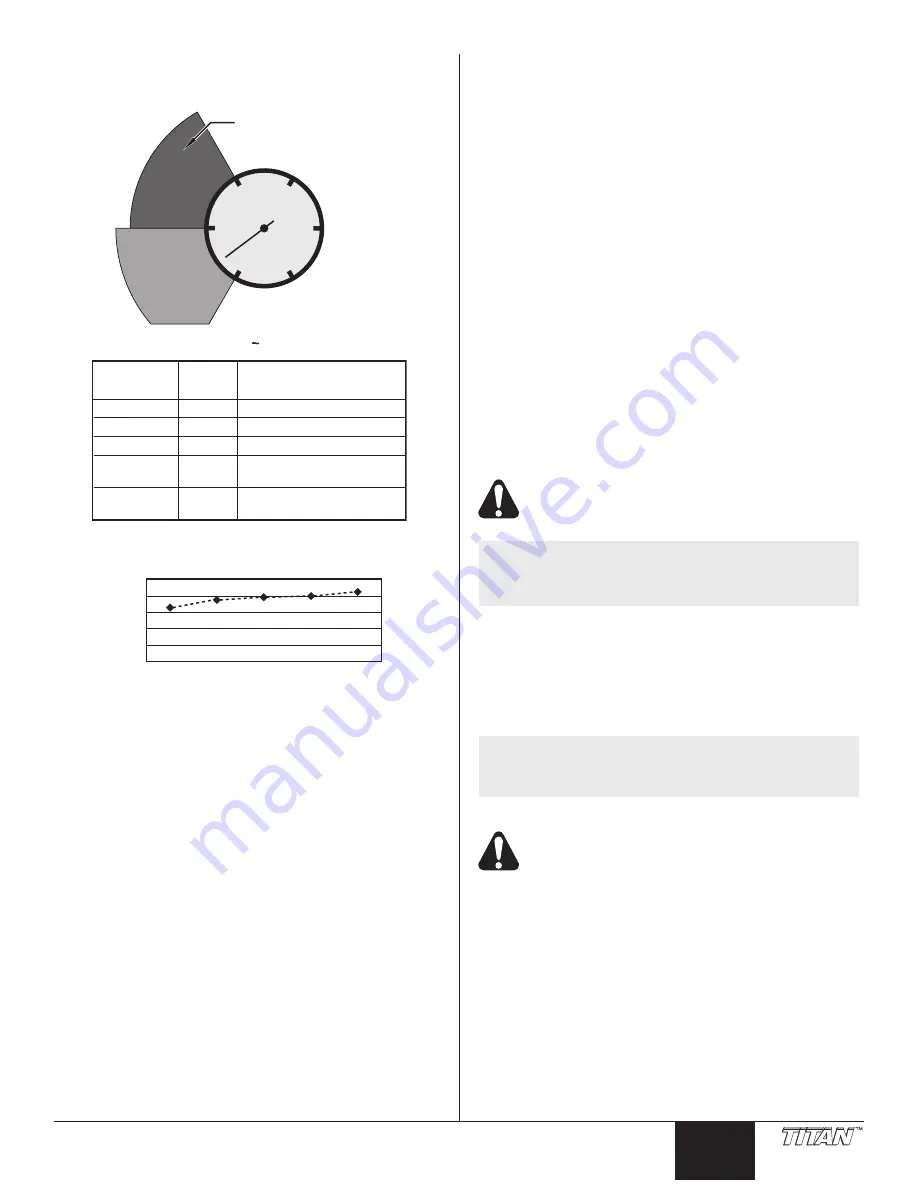

Spray charts

Spraying Pressure Air Consumption

Compressor Pressure Gauge

Pressure

Inside Cap

Compressor Pressure*

Air CFM

6 PSI

6.5

9

15

18

20

(for intermittent use)

24

(for intermittent use)

7.5

7.8

8

8.5

8 PSI

10 PSI

12 PSI

14 PSI

*The pressure at the compressor air outlet

when spraying gun.

18 PSI or

less is HVLP

zone for

continuous

spray

Above 18 PSI is

conventional spray zone

for intermittent use only

Pressure inside air cap (PSI)

Air consumption

(CFM

)

10

8

6

4

2

0

6 PSI

8 PSI

10 PSI

12 PSI

14 PSI

PSI

0

20

40

60

8

0

100

cleanup

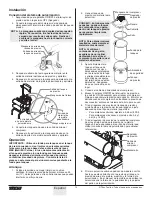

1. Turn off the compressor.

2. Remove the pressure pot hose from the pressure pot.

3. Relieve the pressure from the pressure pot and remove

the pressure pot cover.

4. Remove excess material from the pot (or remove the pot

liner), wiping down the inside of the pot and fluid pick-up

tube.

5. Place a container of the appropriate cleaning solvent into

the pressure pot to clean out the hose and gun.

6. Replace the cover, making sure the pickup tube is inside

the solvent container, and tighten the pot cover.

7. Connect the pressure pot hose, turn on the compressor

and adjust the pressure to 10 psi.

8. Depress the spray gun trigger while pointing the gun into

the material container. This will drain the material into the

container until all material has been pushed through.

9. Continue running the solvent through the hose and gun

until they are completely clean.

maintenance

maintaining the air Filter

The air filter on the compressor must be checked daily for paint

build-up on the filter pads. A clean filter pad is necessary to

prevent damage to the compressor and to maintain maximum

spraying performance.

Never clean the air filter with a flammable liquid or

solvent. Explosive vapors may accumulate in the

air tank and cause an explosion, resulting in

serious injury or death.

NOTE: A replacement filter pad is included with this

unit. Additional filter pads (P/N 600-467) can

be ordered through an authorized Titan service

center.

Regulator with optional moisture separator (P/N

0295742)

A moisture separator is available for separate purchase. A

moisture separator at the compressor air outlet reduces the

amount of water entering the spray gun. Check the moisture

separator sight glass periodically during operation and drain

water as needed.

NOTE: This unit has no other service parts and all

service must be performed by an authorized

service center.

Storage

To reduce the risk of electrical shock, do not

expose to rain. Store indoors.

ImPORTaNT: When storing the unit, use the supplied cord

wrap to protect the power cord.