Performance Series 450e

17

GB

Repairs at the unit

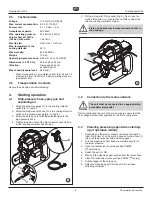

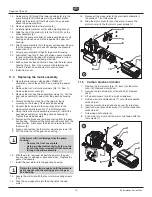

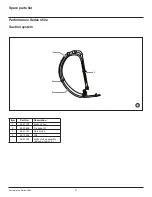

11.6 Replacing the Gears

1. Open the relief valve, valve position PRIME (

k

circulation), switch the unit OFF, and unplug the power

cord.

2. Loosen and remove the four motor cover screws (Fig. 16.

1). Remove the motor cover (2).

3. Disconnect the black and red wires coming from the gear

box housing.

4. Loosen and remove the four motor mounting screws (3).

5. Pull the motor (4) out of the gear box housing (5).

i

If the motor will not dislodge from the pump

housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the

front of the motor crankshaft that extends

through the slider assembly.

6. Inspect the armature gear (6) on the end of the motor for

damage or excessive wear. If this gear is completely worn

out, replace the entire motor.

7. Remove and inspect the 2nd stage gear (7) for damage or

excessive wear. Replace if necessary.

8. Remove and inspect the crankshaft/gear assembly (8) for

damage or excessive wear. Replace if necessary.

9. Reassemble the pump by reversing the above steps.

During reassembly, make sure the thrust washer (9) is in

place.

i

Refill the gear box in the pump housing with five

ounces of Lubriplate GR132 (P/N 0293396).

1

2

3

4

6

7

8

9

5

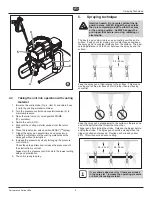

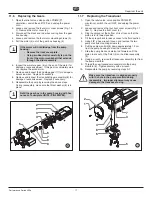

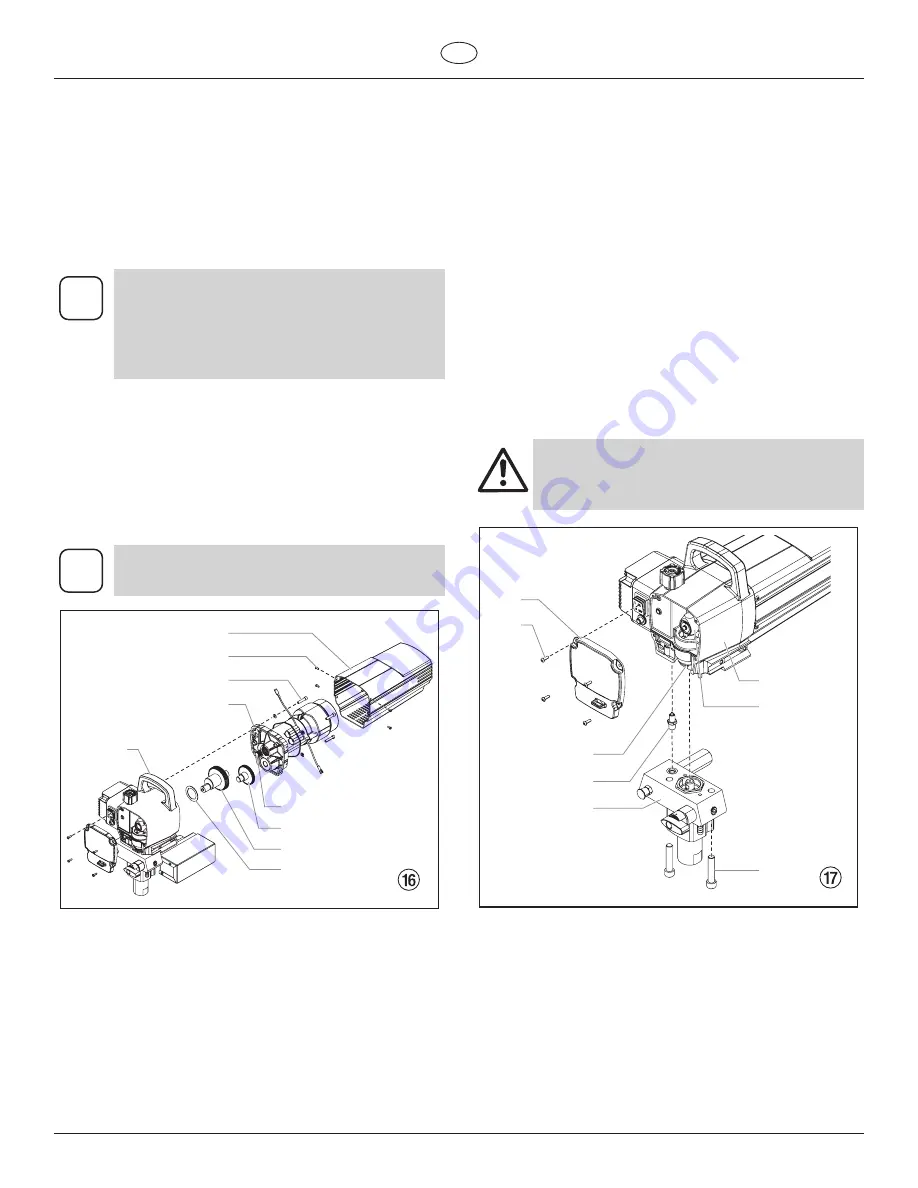

11.7 Replacing the Transducer

1. Open the relief valve, valve position PRIME (

k

circulation), switch the unit OFF, and unplug the power

cord.

2. Loosen and remove the four front cover screws (Fig. 17,

Item 1). Remove the front cover (2).

3. Stop the sprayer at the bottom of its stroke so that the

piston is in its lowest position.

4. Tilt the sprayer back for easy access to the fluid section.

5. Using 3/8” a hex wrench, loosen and remove the two

pump manifold mounting screws (5).

6. Pull the pump manifold (6) down approximately 1.3 cm

from the pump housing to clear the transducer.

7. Slide the pump block and piston rod forward until the

piston rod is out of the T-slot (4) on the slider assembly

(3).

8. Using a wrench, remove the transducer assembly (8) from

the pump manifold.

9. Thread the new transducer assembly into the pump

manifold (6). Tighten securely with a wrench.

10. Reassemble the pump by reversing steps 2–7.

Make sure the transducer is aligned properly

with the hole in the pump manifold during

reassembly. Improper alignment may cause

damage to the transducer o-ring.

2

1

4

6

8

5

3

7