Performance Series 450e

5

GB

Safety regulations

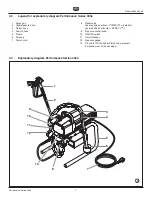

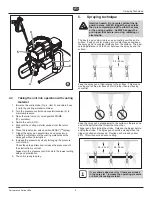

General view of application

HAZARD: eXPLOSION HAZARD Due TO

INCOMPATIBLe MATeRIALS

Will cause severe injury or property damage.

PReVeNTION

:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such

as methylene chloride and 1,1,1 - trichloroethane.

They are not compatible with aluminum and may

cause an explosion. If you are unsure of a material’s

compatibility with aluminum, contact your coating’s

supplier.

HAZARD: GeNeRAL

This product can cause severe injury or property

damage.

PReVeNTION:

• Read all instructions and safety precautions before

operating equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

• Pulling the trigger causes a recoil force to the hand

that is holding the spray gun. The recoil force of the

spray gun is particularly powerful when the tip has

been removed and a high pressure has been set on

the airless pump. When cleaning without a spray tip,

set the pressure control knob to the lowest pressure.

• Use only manufacturer authorized parts. User

assumes all risks and liabilities when using parts that

do not meet the minimum specifications and safety

devices of the pump manufacturer.

• Before each use, check all hoses for cuts, leaks,

abrasion or bulging of cover. Check for damage or

movement of couplings. Immediately replace the hose

if any of these conditions exist. Never repair a paint

hose. Replace it with another earthed high-pressure

hose.

• Make sure power cord, air hose and spray hoses are

routed in such a manner to minimize slip, trip and fall

hazard.

• Clean up all material and solvent spills immediately to

prevent slip hazard.

• ALWAYS follow the material manufacturer’s

instructions for safe handling of paint and solvents.

• Do not use this unit in workshops that are covered

under the explosion prevention regulations.

• Always unplug cord from outlet before working on

equipment (electric units only).

• Always keep the power cord plug in sight during usage

to prevent any accidental shutdown or startup.

• Wear ear protection. This unit can produce noise

levels above 85 dB(A).

• Never leave this equipment unattended. Keep away

from children or anyone not familiar with the operation

of airless equipment.

• Do not move unit while unit is running.

• Do not spray on windy days.

HAZARD: HAZARDOuS VAPORS

Paints, solvents, insecticides, and other materials

can be harmful if inhaled or come in contact with

body. Vapors can cause severe nausea, fainting, or

poisoning.

PReVeNTION:

• Use a respirator or mask if vapors can be inhaled.

Read all instructions supplied with the mask to be sure

it will provide the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating

manufacturer.

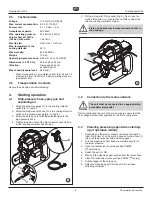

1.1

earthing Instructions

PE

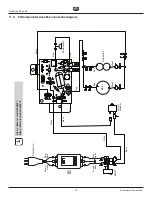

Electric models must be earthed. In the event of an

electrical short circuit, earthing reduces the risk of electric

shock by providing an escape wire for the electric current.

This product is equipped with a cord having an earthing

wire with an appropriate earthing plug. The plug must be

plugged into an outlet that is properly installed and earthed

in accordance with all local codes and ordinances.

DANGeR — Improper installation of the earthing plug

can result in a risk of electric shock. If repair or

replacement of the cord or plug is necessary, do not

connect the green earthing wire to either blade

terminal. The wire with insulation having a green outer

surface with or without yellow stripes is the earthing

wire and must be connected to the earthing pin.

Check with a qualified electrician or serviceman if the earthing

instructions are not completely understood, or if you are in doubt as to

whether the product is properly earthed. Do not modify the plug provided.

If the plug will not fit the outlet, have the proper outlet installed by a

qualified electrician.

Caution – The power cord for this equipment acts as an

emergency stop/emergency switching off device. The

power cord must be placed near an easily accessible,

unobstructed socket-outlet.

Work or repairs at the electrical equipment:

These may only be carried out by a skilled electrician. No liability is

assumed for incorrect installation.

A list of the materials used in the construction of the equipment will be

made available on request to validate compatibility with the coating

materials to be used.

Operating Temperature

This equipment will operate correctly in its intended ambient, at a

minimum b10°C and +40°C.

Relative Humidity

The equipment will operate correctly within an environment at 50% RH,

+40°C. Higher RH may be allowed at lower temperatures.

Measures shall be taken by the Purchaser to avoid the harmful effects of

occasional condensation.

Altitude

This equipment will operate correctly up to 2100m above mean sea level.

Transportation and Storage

This equipment will withstand, or has been protected against,

transportation and storage temperatures of -25°C to +55°C and for short

periods up to +70°C.

It has been packaged to prevent damage from the effects of normal

humidity, vibration and shock.