5

© Titan Tool Inc. All rights reserved.

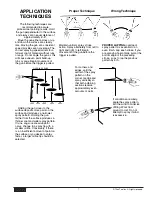

1) Always keep spray area well ventilated.

Always keep the turbine a minimum of 20 feet

from spray activity.

2) Always follow the coating or solvent

manufacturer’s safety precautions and

warnings.

3) Never spray flammable materials near open

flames, pilot lights or any other source of

ignition.

4) Always wear spray masks and protective eye

wear while spraying.

5) Never alter or modify any part of this

equipment; doing so could cause it to

malfunction.

6) Never attempt to service or assemble the

turbine while it is plugged in.

7) Never attempt to clean the exterior of the

turbine while it is plugged in. CAUTION: TO

REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT EXPOSE TO RAIN – STORE

INDOORS

8) Never point the spray gun at anyone or any

part of the body.

9) Never leave equipment unattended. Keep

away from children or anyone not familiar

with the operation of spray equipment.

GROUNDING INSTRUCTIONS: This

product should be grounded. In the event of an

electrical short circuit, grounding reduces the

risk of electric shock by providing an escape

wire for the electric current. This product is

equipped with a cord having a grounding wire

with an appropriate grounding plug.The plug

must be plugged into an outlet that is properly

installed and grounded in accordance with all

local codes and ordinances.

DANGER - Improper installation of the

grounding plug can result in a risk of electric

shock. If repair or replacement of the cord or

plug is necessary, do not connect the grounding

wire to either flat blade terminal. The wire with

insulation having an outer surface that is green

(with or without yellow stripes) is the grounding

wire. Check with a qualified electrician or

serviceman if the grounding instructions are not

completely understood, or if in doubt as to

whether the product is properly grounded.

Do not modify the plug provided; if it will not fit

the outlet, have the proper outlet installed by a

qualified electrician.

• This product is for use on a nominal 120-volt

circuit and has a grounding plug that looks

like the plug illustrated.

• Make sure that the product is connected to an

outlet having the same configuration as the

plug. No adapter should be used with this

product.

EXTENSION CORDS: Use only a 3-wire

extension cord that has a 3-slot receptacle that

will accept the plug on the pump. Make sure

your extension cord is in good condition. When

using an extension cord, be sure to use one

heavy enough to carry the current this pump will

draw.

For lengths less than

Use extensio

gauge

25 ft.

16 AWG

50 ft.

14 AWG

100 ft.

12 AWG

150 ft.

10 AWG

An undersized cord will cause a drop in line

voltage resulting in loss of power and

overheating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the

heavier the cord.

FIRE OR EXPLOSION HAZARD

FLUID SECTION—SOLVENTS

Halogenated Hydrocarbon solvents can cause an explosion when used with aluminum or galvanized components in a closed (pressurizable ) fluid

system (pumps, heaters, filters, valves, spray guns, tanks, etc.). The explosion could cause serious injury, death and/or substantial property damage.

Cleaning agents, coatings, paints, etc. may contain Halogenated Hydrocarbon solvents. Titan Tool Inc. spray equipment includes aluminum or

galvanized components and will be affected by Halogenated Hydrocarbon solvents. DO NOT USE HALOGENATED HYDROCARBONS IN TITAN

EQUIPMENT.

EXPLANATION OF THE HAZARD

There are three key elements to the Halogenated Hydrocarbon (HHC) solvent hazard. These elements are:

1. The presence of HHC solvents.

2. Aluminum or galvanized parts.

3. Equipment capable of withstanding pressure.

When all three elements are present, the result can be an extremely violent explosion. The reaction can be sustained with very little aluminum or

galvanized metal: any amount of aluminum is too much. The reaction is unpredictable. Prior use of an HHC solvent without incident (corrosion or

explosion) does NOT mean that such use is safe.

HALOGENATED SOLVENTS –

DEFINITION : Any hydrocarbon solvent containing any of the elements as listed below:

Consult your material supplier to determine whether your solvent or coating contains Halogenated Hydrocarbon Solvents.

Fluorine (F) “-fluor-”

Bromine (Br) “-bromo-”

Examples (not all-inclusive):

FLUOROCARBON SOLVENTS:

Dichlorofluoromethane

Trichlorofluoromethane

CHLORINATED SOLVENTS:

Carbon tetrachloride

Chloroform

Ethylene dichloride

BROMINATED SOLVENTS:

Ethylene dibromide

Methylene chlorobromide

Methyl bromine

TRICHLOROETHANE:

Trichloroethylene

Monochlorotoluene

Chlorine (CL) “-chloro-”

Iodine (I) “-Iodo-”

METHYLENE CHLORIDE OR

DICHLOROMOETHANE:

Monochlorobenzene

Orthodichlorobenzene

Perchloroethylene

IODINATED SOLVENTS:

N-butyl iodide

Methyl iodide

Ethyl iodide

Propyl iodide

WARNING

DO NOT USE EQUIPMENT BEFORE READING THIS SECTION

Never operate this unit unless it is properly grounded.

A fire or explosion hazard is present when spraying flammable materials. Please

read and understand the following steps to assure safe operation of your sprayer.

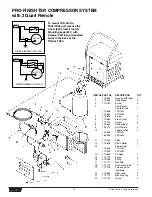

Please read the additional WARNINGS for the TSR System on page 11

.