6

© Titan Tool Inc. All rights reserved.

START-UP PROCEDURES

Step 1: Prepare the Paint

A. Prepare the material to be sprayed

according to paint manufacturers

recommendations.

B. Strain the paint before each use. 770-

119 Cone Strainer provided.

C. Thin the material to be sprayed with the

recommended solvent. Most materials

need to be thinned to obtain spraying

consistency. To achieve the proper

viscosity for spraying, either a viscosity

cup can be used or trial and error.

D. If a viscosity cup is not available, thin

the materials to a point where you will

achieve a one second interval between

drops after a paint stick has been

inserted and removed from paint.

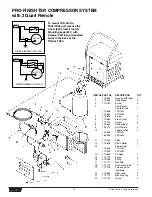

Step 2: Gun and Turbine Set-Up

A. With the turbine switch in the off

position, plug into a grounded outlet at

least 20 feet from spray activity.

B. Attach air atomizing hose to turbine.

C. Attach quart cup to gun and attach tube

from gun to cup, attach air hose to

bottom of the gun. Make sure that

everything is secure before spraying.

Step 3: Spray Gun Adjustments

The “Pro-Finish” gun comes equipped with

a .051 fluid nozzle and needle and our #0

medium air cap. Always test your spray

pattern on a test surface before you

begin to work.

A. Fan size adjustment is controlled by

turning the air cap retainer ring.

Clockwise will increase fan width,

counterclockwise will decrease fan

width.

B. Top knob controls air volume. Clockwise

will decrease air flow.

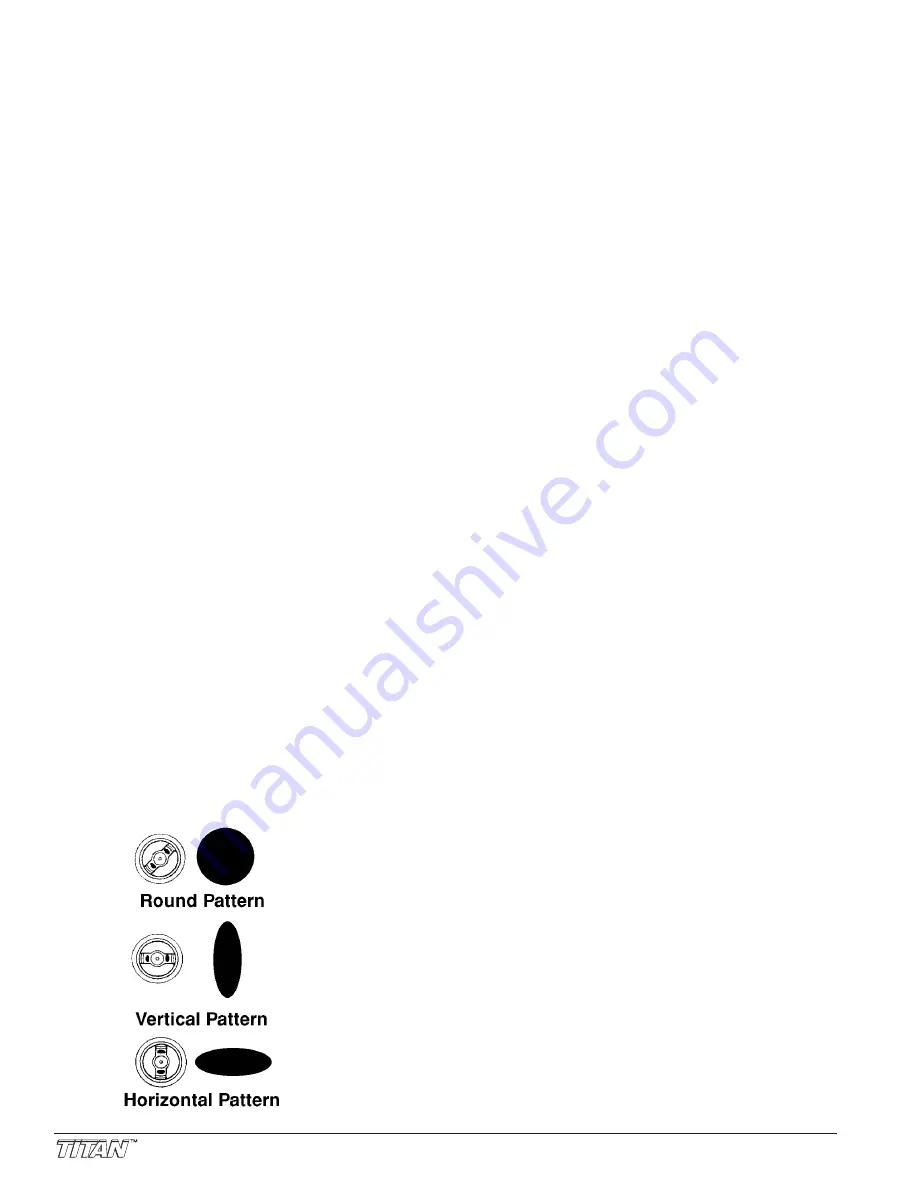

C. A round, horizontal or vertical fan

pattern can be achieved by rotating air

cap as shown by the diagrams below.

D. A round pattern will require less material

flow than a wide pattern. Turning the

lower knob clockwise will decrease fluid

flow; counter-clockwise will increase

fluid flow.

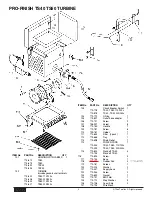

Step 4: Fluid Nozzle / Needle / Air Cap

Selection

If after all of the appropriate adjustments

are made poor results are obtained, it may

be necessary to change to a different fluid

nozzle / needle or air cap. Refer to our

selection chart to match the appropriate

components to the material being sprayed.

Note: The smaller the air cap the greater

atomization.

A. To change fluid nozzle and tip remove

air cap 101 and indexing retainer 103.

B. Squeeze trigger and with a wrench

remove fluid tip 105.

(Use Fluid Tip Tool ( 773-134), supplied,

not pictured)

C. Remove rear Adjustment Knob (128).

Remove Spring (127) and Needle (126)

D. Reassemble in reverse order A thru C.

Note: Never use lubricants containing

silicones. Silicone will adversely

affect spray finishes and is difficult to

get rid of once on equipment.

The following techniques are

recommended to assure

professional painting results. Hold

the gun perpendicular to the surface

and always at an equal distance of

approximately 6”-8”.

Move the gun either across or up

and down the surface at a steady

rate. Moving the gun at a consistent

speed provides even coverage. The

correct spraying speed allows for a

full wet coat of material without runs

or sags. Do not angle the gun as this

will cause uneven paint build-up,

runs or sags. Begin movement of

the gun before the trigger is pulled.

Holding the gun closer to the

surface deposits more paint on the

surface and produces a narrower

spray pattern. Holding the gun

farther from the surface produces a

thinner coat and wider spray pattern.

If runs, sags or excessive paint

occur, change to a spray tip with a

smaller orifice. Conversely, if there is

an insufficient amount of paint on

the surface or you desire to spray

faster, a larger orifice tip should be

selected.

USER'S MAINTENANCE

INSTRUCTIONS

During storage the power cord

must be coiled around cord holder to

avoid damage.

CLEANING PROCEDURES

The Titan Pro-Finish system has

been constructed with the finest

materials to assure trouble free

operation and durability.

However, like any paint tool,

proper cleaning is essential for

optimum performance to be

maintained. Always clean

thoroughly after each use.

Step 1. Pour remaining material in

the quart cup back into the original

container. For single component

materials ONLY. For catalyzed

material, consult coating mfg.

recommendation.

Step 2. Pour a small amount of

solvent in the cup. Swirl the solvent

around in the cup and empty.

Step 3. Thoroughly clean the interior

of the cup and wipe dry.

Step 4. Pour a small amount of

solvent into cup and spray through

the gun to clean fluid nozzle and

needle.

Step 5. After extended use it might

be necessary to remove the fluid

nozzle, needle and air cap and clean

by hand, with a soft brush. (Part No.

770-118 provided). Do not use a

wire brush or hard tools that could

damage the components. Also clean

the inside of the gun with solvent

and a soft brush. Reassemble gun

and test with mineral spirits.

Step 6. Clean the exterior of the gun

using solvent. NEVER soak the gun

in solvent. Some solvents can

damage internal seals.

Step 7. Check turbine filter, clean or

replace. (Never use solvent to

clean turbine filter, blow clean

with compressed air or replace.)

Please dispose of cleaning

solvent and unused coatings in

an environmentally safe fashion.

Consult with material

manufacturer on proper

procedure.