8

© Titan Tool Inc. All rights reserved.

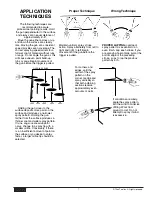

TROUBLESHOOTING - FINISH PROBLEMS

PROBLEM . . . . . . . . . . . . . . . . . . .PROBABLE CAUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .REMEDY

Orange Peel . . . . . . . . . . . . . . .Material is too viscous . . . . . . . . . . . . . . . . . . . . . . . . . . .Thin MaterialConsult coating

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . manufacturer recommendations

. . . . . . . . . . . . . . . . . . . . . . .Improper Solvent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Use recommended solvent

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Consult coating manufacturer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . recommendations

. . . . . . . . . . . . . . . . . . . . . . .Insufficient atomizing air . . . . . . . . . . . . . . . . . . . . . . . . . .Change to a smaller air cap

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See chart below

Runs and Sags . . . . . . . . . . . . .Too much solvent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Add material

. . . . . . . . . . . . . . . . . . . . . . .Gun too close to surface . . . . . . . . . . . . . . . . . . . . . . . . . .Reduce flow by turning yellow

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .regulator knob counterclock-

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .wise. Move further from the surface.

. . . . . . . . . . . . . . . . . . . . . . .Wrong fluid nozzle & needle . . . . . . . . . . . . . . . . . . . . . . .Replace. See chart below

Blushing . . . . . . . . . . . . . . . . . .Fast drying thinner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Add retarder

Pin Holing and

Solvent Pops . . . . . . . . . . . . . .Trapped solvents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Reduce fluid flow and apply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .lighter coats. Use faster solvent

. . . . . . . . . . . . . . . . . . . . . . .Insufficient atomization . . . . . . . . . . . . . . . . . . . . . . . . . . .Thin material or use a smaller air cap

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See chart below

Blistering . . . . . . . . . . . . . . . . .Surface not primed properly . . . . . . . . . . . . . . . . . . . . . . .Use appropriate primer

. . . . . . . . . . . . . . . . . . . . . . .Surface moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Dry

Coarse Finish . . . . . . . . . . . . . .Improper cleaning of surface . . . . . . . . . . . . . . . . . . . . . .Clean immediately before spraying

TROUBLESHOOTING

PROBLEM . . . . . . . . . . . . . . . . . . .PROBABLE CAUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .REMEDY

Paint will not Flow . . . . . . . . . .1) Blockage in fluid nozzle . . . . . . . . . . . . . . . . . . . . . . . .1) Clean or replace

. . . . . . . . . . . . . . . . . . . . . . .2) Loss of air pressure in cup . . . . . . . . . . . . . . . . . . . . . .2) Search for air leaks in tube and

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

sealing gasket

. . . . . . . . . . . . . . . . . . . . . . .3) Dirty or stuck one way valve . . . . . . . . . . . . . . . . . . . . .3) Clean or replace

. . . . . . . . . . . . . . . . . . . . . . .4) Loose fluid nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4) Tighten

. . . . . . . . . . . . . . . . . . . . . . .5) Paint tubes loose or . . . . . . . . . . . . . . . . . . . . . . . . . . .5) Tighten or replace

. . . . . . . . . . . . . . . . . . . . . . .

damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .6) Coating is too thick . . . . . . . . . . . . . . . . . . . . . . . . . . . .6) Thin the coating

Inconsistent Spray . . . . . . . . . .1) Running out of paint . . . . . . . . . . . . . . . . . . . . . . . . . . .1) Fill cup or pot

Pattern (Spits and . . . . . . . . . .2) Loose fluid tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2) Tighten

Sputters) . . . . . . . . . . . . . . . . .3) Loss of fluid pressure . . . . . . . . . . . . . . . . . . . . . . . . . .3) Search for air leaks or

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

blockages

Leakage at . . . . . . . . . . . . . . .1) Damaged fluid needle . . . . . . . . . . . . . . . . . . . . . . . . . .1) Replace

Front of Gun . . . . . . . . . . . . . . .2) Wrong size fluid needle . . . . . . . . . . . . . . . . . . . . . . . .2) Replace

. . . . . . . . . . . . . . . . . . . . . . .3) Dirty fluid nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3) Clean

. . . . . . . . . . . . . . . . . . . . . . .4) Loose fluid nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4) Tighten

Distorted Spray . . . . . . . . . . . .1) Dirty air cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1) Clean or replace

Pattern . . . . . . . . . . . . . . . . . . .2) Damaged fluid nozzle or . . . . . . . . . . . . . . . . . . . . . . . .2) Replace

. . . . . . . . . . . . . . . . . . . . . . .

needle

. . . . . . . . . . . . . . . . . . . . . . .3) Fluid nozzle partially . . . . . . . . . . . . . . . . . . . . . . . . . .3) Clean

. . . . . . . . . . . . . . . . . . . . . . .

clogged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTION CHART

Fluid Needle/Nozzle

Air Cap

Material

Size

Part No. Size

Part No. Consult paint manufacturers for proper thinning recommendations.

.029

773-151 #3

773-159 Acrylic lacquers, stains, dyes

.043

773-152 #2

773-158 Waterborn clears, epoxy, polyurethane, automotive, base coat, acrylic urethanes & enamels

.051

773-153 #0

773-156 Full bodied stains, alkyd enamels, water born enamels

.073

773-154 #1

773-157 Finish grade latexes, alkyd wall paints

.118

773-155 #4

773-160 Heavy-bodied multi-color or textured coatings