22

© Titan Tool Inc. All rights reserved.

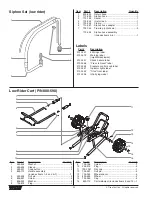

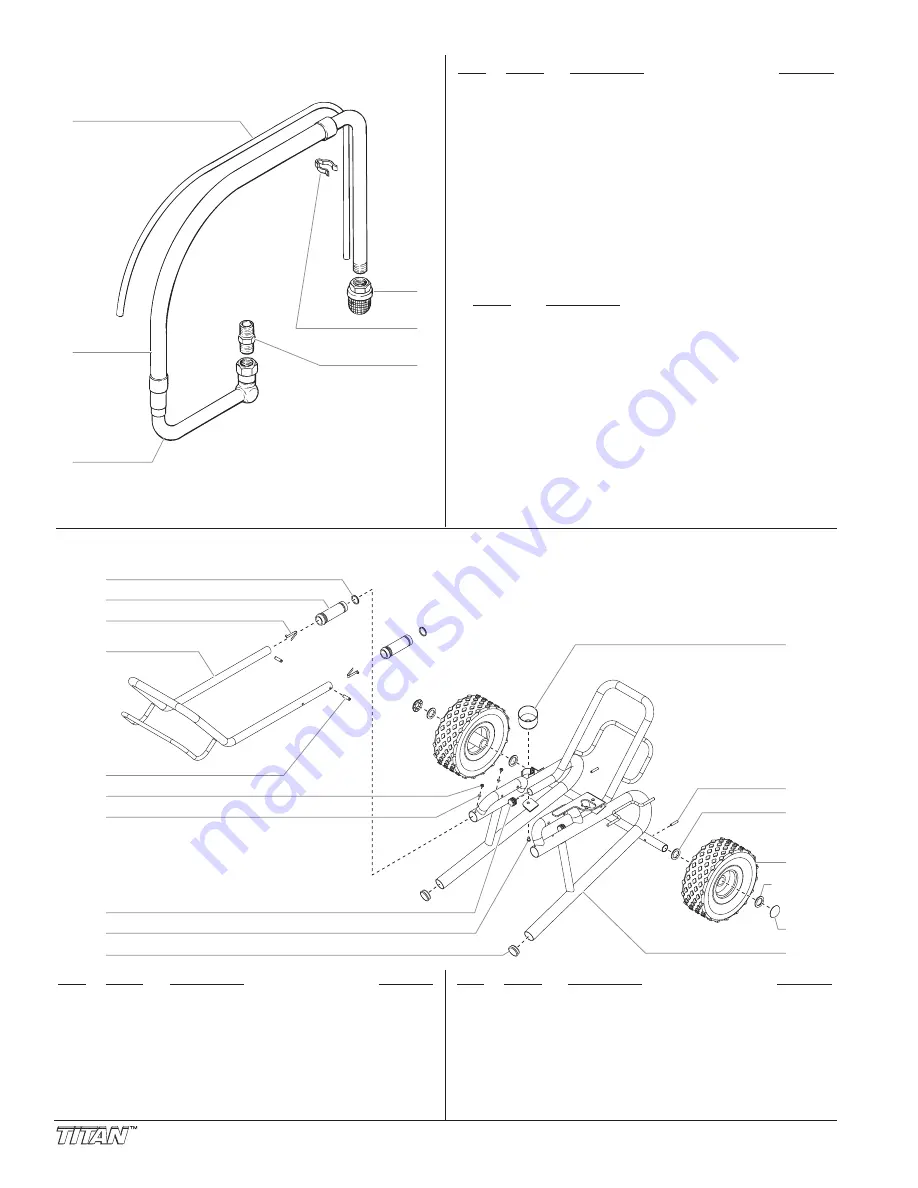

Low Rider Cart (P/N 800-590)

1

2

3

4

5

6

7

8

9

10

11

12

13

13

16

15

14

Item

Part #

Description

Quantity

1

590-506

Washer........................................................2

2

590-504

Sleeve.........................................................2

3

590-507

Snap button ................................................2

4

800-113

Handle assembly

(includes items 1–3 and 5–7) .....................1

5

590-508

Roll pin........................................................2

6

856-921

Screw..........................................................4

7

856-002

Washer........................................................4

8

700-674

Plug.............................................................2

Item

Part #

Description

Quantity

9

704-188

Screw..........................................................1

10

335-018

Plug.............................................................2

11

700-1041

Drip cup ......................................................1

12

704-291

Roll pin........................................................2

13

704-354

Wheel spacer..............................................4

14

800-593

Wheel..........................................................2

15

704-355

Cap .............................................................2

16

800-112

Cart weldment (includes items 8 and 10)...1

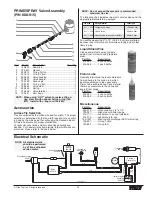

Siphon Set (low rider)

1

2

3

4

5

6

Item

Part #

Description

Quantity

1

800-903

Return hose ................................................1

2

710-203

Siphon hose................................................1

3

710-195

Swivel .........................................................1

4

710-046

Inlet screen .................................................1

5

730-334

Clamp .........................................................1

6

710-081

Siphon hose adapter ..................................1

7

700-742

Tie wrap (not shown) ..................................3

710-204

Siphon hose assembly

(includes items 2–6) ...................................1

Labels

Part #

Description

313-1651

840i logo label

313-1673

Warning label

(injection/explosion)

313-1847

Shock hazard label

313-1658

“Press to Reset” label

313-1848

Pressure control knob label

313-1867

Indicator lights label

313-1652

“Titan” front label

313-1906

Infinity logo label