English

English

10

© Titan Tool Inc. All rights reserved.

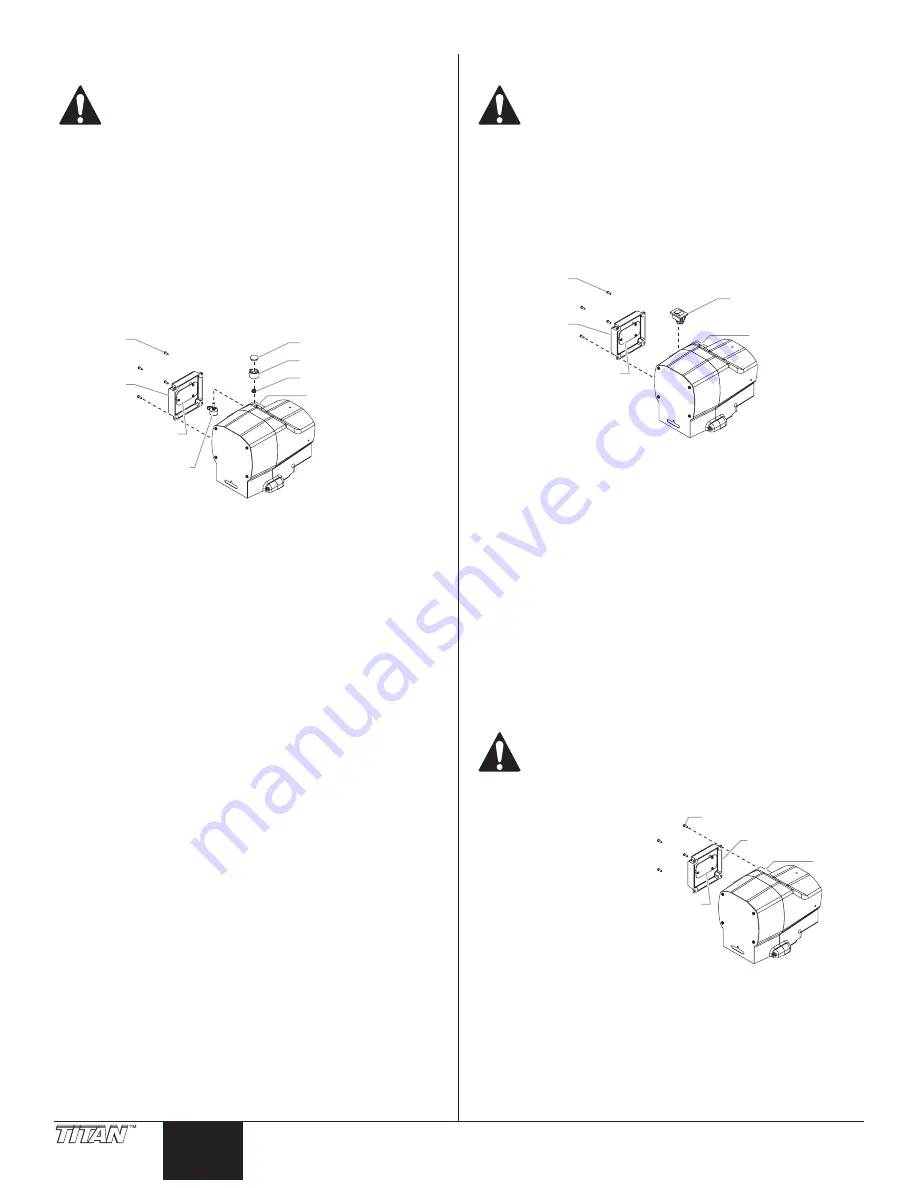

Replacing the Potentiometer

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. use Titan ESD

wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

1. Perform the Pressure Relief Procedure.

2. Pry off the pressure control knob cap to expose the knob

tension nut.

3. Turn the pressure control knob fully counterclockwise to the

minimum pressure setting.

4. Using a 5/16” socket, loosen the tension nut in the center of

the knob. Remove the knob.

5. Using a Phillips screwdriver, remove the four screws that

secure the electronic pressure control (EPC) assembly to the

EPC housing. Carefully remove the EPC assembly from the

housing. Gently move the assembly away from the sprayer

and allow the assembly to hang from the housing.

EPC

Housing

Pressure Control Knob

Seal Nut

Cap

EPC

Board

EPC

Assembly

EPC

Assembly

Screw

Potentiometer

6. Hold the potentiometer inside the EPC housing while using

a 1/2” thin wall socket to remove the seal nut that secures

the potentiometer to the mounting plate. Remove the

potentiometer from the EPC housing.

7. Carefully remove the potentiometer wires from their

connection point on the EPC board.

8. Insert the stem of the new potentiometer through the hole in

the mounting plate from inside the EPC housing. Position the

protruding tab on the potentiometer face into the hole on the

underside of the mounting plate (the wires will face the open

side of the EPC housing).

9. Thread the seal nut onto the threaded portion of the stem and

tighten using a 1/2” thin wall socket.

ImPORTANT: Do not over-tighten the seal nut.

10. Turn the potentiometer stem fully counterclockwise.

11. Place the pressure control knob on the potentiometer stem

with the indicator tab resting at the “minimum pressure” tab

on the mounting plate.

12. Tighten the knob tension nut using a 5/16” socket.

ImPORTANT: Do not over-tighten the knob tension nut. Over-

tightening will damage the potentiometer.

13. Connect the potentiometer wires to the EPC board. The

protruding tab on the EPC board connector will mate with the

slot on the potentiometer wires connector. The connector

on the end of the potentiometer wires and the connector

on the EPC board will mate only one way. Do not force the

connectors together.

14. Carefully place the EPC assembly over the EPC housing taking

care not to pinch any wires.

15. Install the four screws that secure the EPC assembly to the EPC

housing. Tighten securely.

Replacing the Sprayer ON/OFF Switch

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. use Titan ESD

wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

1. Perform the Pressure Relief Procedure.

2. Using a Phillips screwdriver, remove the four screws that

secure the electronic pressure control (EPC) assembly to the

EPC housing. Carefully remove the EPC assembly from the

housing. Gently move the assembly away from the sprayer

and allow the assembly to hang from the housing.

3. Locate the bottom of the sprayer ON/OFF switch inside the

EPC housing.

EPC

Housing

Sprayer ON/OFF

Switch

EPC

Board

EPC

Assembly

EPC

Assembly

Screw

4. Disconnect the switch wires from the sprayer ON/OFF switch.

Remember the locations of each of the two wires (label the

wires, if necessary).

5. Depress the mounting tabs on each corner of the sprayer ON/

OFF switch inside the EPC housing and remove the switch

through the top of the housing.

6. Snap the new sprayer ON/OFF switch into the switch hole in

the EPC housing.

7. Connect the two switch wires to the new sprayer ON/

OFF switch. Make sure the wires are connected to the

corresponding terminals from which they were removed (refer

to the labels created earlier in this procedure or the electrical

schematic in the Parts List section of this manual).

8. Carefully place the EPC assembly over the EPC housing taking

care not to pinch any wires.

9. Install the four screws that secure the EPC assembly to the EPC

housing. Tighten securely.

Replacing the Transducer

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. use Titan ESD

wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

1. Perform the Pressure Relief Procedure.

EPC

Housing

EPC Assembly Screw

EPC Assembly

EPC

Board

2. Using a Phillips

screwdriver, remove the

four screws that secure

the electronic pressure

control (EPC) assembly

to the EPC housing.

Carefully remove the

EPC assembly from the

housing. Gently move

the assembly away from

the sprayer and allow the

assembly to hang from

the housing.

3. Locate the transducer wire in the EPC housing. This wire will

be protruding from a hole in the lower left hand corner of the

EPC housing. Disconnect this wire from the EPC board (it has

a phone jack-style connector).

4. Break off the locking tab from the phone jack-style connector

at the end of the transducer wire.

5. Using a 7/8” open-end wrench, loosen and remove the fluid

hose from the fitting on the bottom of the filter assembly.