© Titan Tool Inc. All rights reserved.

7

English

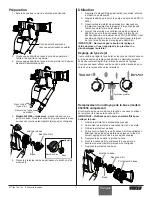

Maintenance

cleaning / changing the Filter

1. Relieve spray gun and unit pressure.

2. Lock the spray gun by activating the trigger lock.

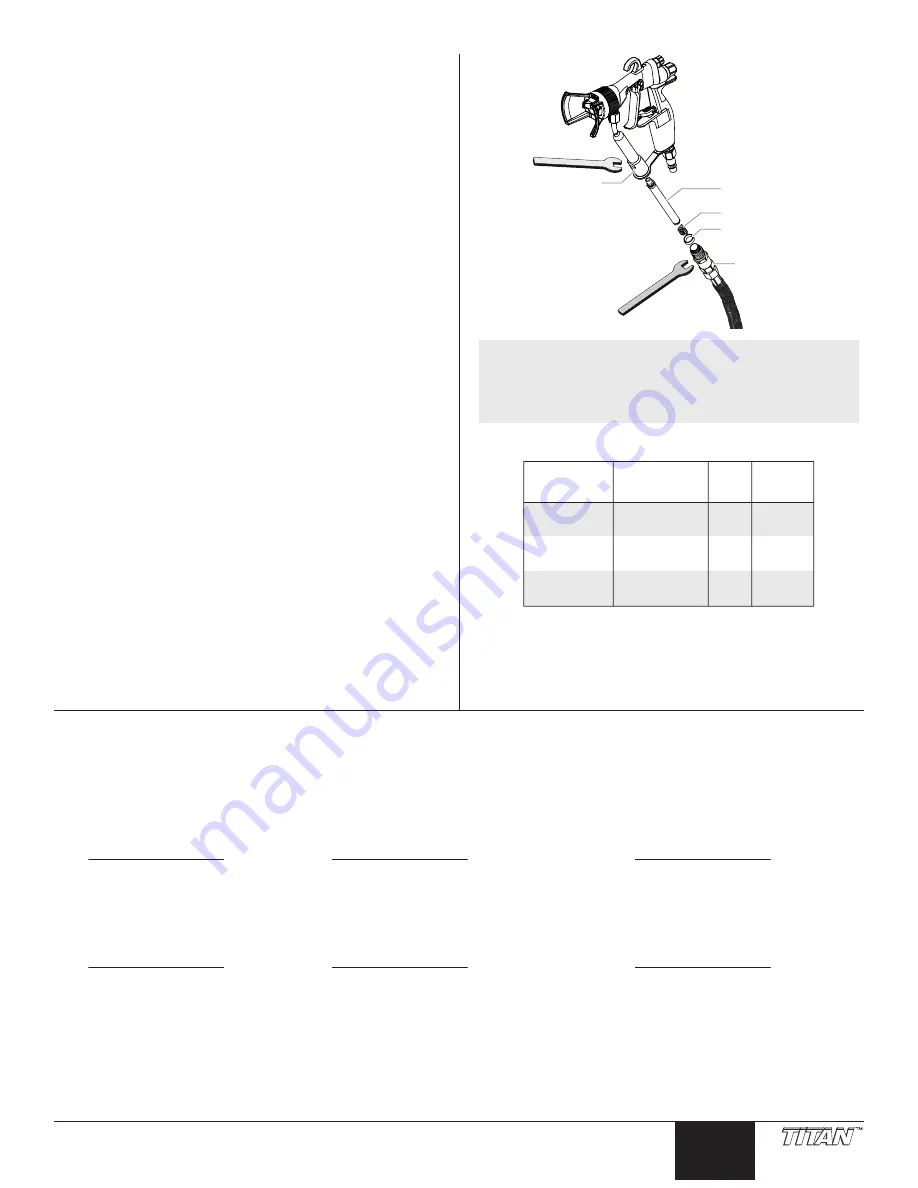

3. Hold open-ended wrench on flats of filter housing and

remove material inlet fitting with a second wrench.

4. Holding the material tube at the wrench flats with one

wrench, unscrew the material inlet fitting another wrench.

Remove seal.

5. Pull out the spring and filter.

6. Rinse the filter in a cleaning solvent or exchange with a

new filter.

7. Clean the filter housing and material inlet fitting with the

appropriate cleaning solvent.

8. Push the cone end of the new or cleaned filter into the into

the filter housing.

9. Make sure the spring and seal are in position in the

material inlet fitting.

10. Holding the filter housing at the wrench flats with one

wrench, thread the material inlet fitting into the material

tube. Tighten securely.

11. Reattach the high pressure hose to the material inlet

fitting.

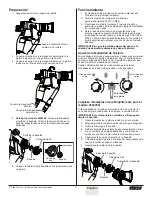

Material

Inlet Fitting

Seal

Spring

Filter

Filter

housing

NOTE

: Make sure the correct filter is being used for the

tip and material being used (refer to the “Flat Tip

chart” and the “XL-1 Reversible airless Spray

Tip” sections).

Gun Filter chart

Part

Number

For Tip Sizes

Filter

Mesh

Color of

Filter

Body

0089960 (2 pk.)

0.007" – 0.011"

180

red

0089959 (2 pk.)

0.013" – 0.015"

100

yellow

0089958 (2 pk.)

0.018" – 0.036"

50

white

Problem

A. Insufficient material supply.

B. Poor spraying pattern.

C. Leaking air valve.

cause

1. Material pressure set too low.

2. Blocked spray gun filter or pump high

pressure filter.

3. Tip is blocked.

4. Tip is too small.

1. Tip is too large.

2. Material pressure at the pump is set too

low.

3. Material viscosity is too high.

4. Atomizing air is set incorrectly.

5. Worn tip.

1. Damaged air valve seal.

Solution

1. Increase the material pressure at pump.

2. Clean or replace the gun filter and/or pump high

pressure filter.

3. Clean the tip.

4. Select a larger tip.

1. Select a smaller tip.

2. Increase the material pressure at the pump.

3. Dilute the material according to the material

manufacturer’s instructions.

4. Adjust the atomizing air using the gun air adjustment

knob or pressure regulator at the compressor.

5. Replace with a new tip.

1. Replace the air valve seal.

Troubleshooting