EN

5

GENERAL INFORMATION

MODELS

This pump is available in stand models (1500 / 1700) and cart

models (1700 Pro / 1900 Pro).

Some of the graphics in this manual may not exactly match

your sprayer and spray gun. All information and instructions

given in this manual applies to all models except where noted.

The type of spray gun and length of spray hose included

depends upon the pump model you have. Refer to the chart

below for details.

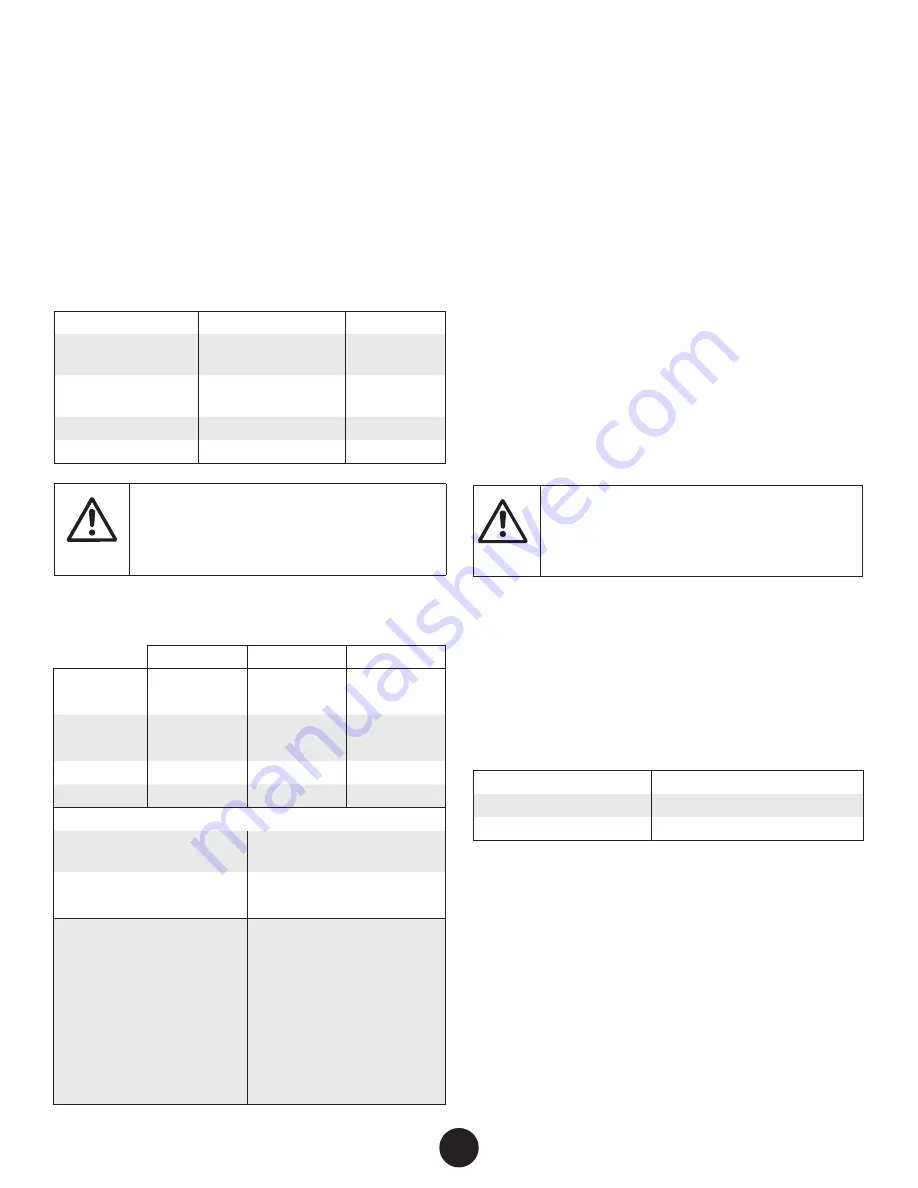

Pump Model

gun Model

Hose Length

ControlMax 1500

Hybrid (plastic/metal

handle)

25 ft.

ControlMax 1700

Hybrid (plastic/metal

handle)

30 ft.

ControlMax 1700 Pro Metal (all metal handle)

50 ft.

ControlMax 1900 Pro Metal (all metal handle)

50 ft.

The ControlMax can only be used with spray

tips, hoses or spray guns that are ControlMax

compatible. Do not use any non-ControlMax

accessories with this system.

SPECIFICATIONS

1500

1700

1900

Maximum

Pressure

1500 PSI

(10.3 MPa)

1500 PSI

(10.3 MPa)

1600 PSI

(11.1 MPa)

capacity

0.29 GPM

(1.1 LPM)

0.33 GPM

(1.25 LPM)

0.40 GPM

(1.5 LPM)

Max. tip

0.015

0.017

0.019

Horsepower

0.55

0.6

0.7

all models:

Power requirement

15 amp minimum circuit on

115 VAC, 60 Hz current

generator power

requirement

5000 Watt

(disable idle-down feature)

Overheating protection

This sprayer has a built-

in protective device to

prevent damage from

overheating. The sprayer

may automatically shut

down after heavy use. If this

happens, turn switch OFF (0),

unplug the sprayer and allow

to cool for 20-30 minutes and

resume spraying.

CAPABILITY

Sprays a variety of paints (oil-based and latex), primers, stains,

preservatives and other nonabrasive materials.

DO NOT USE!

This pump should not be used with textured materials, block

filler, lacquers, industrial enamels, or asphalt sealer or materials

containing HHC. See coating supplier if flash point is not listed

on the container.

SAFETY FEATURES

Spray gun trigger lock and pressure diffuser; built-in tip safety

guard; PRIME/SPRAY knob for safe pressure release. Conforms

to UL STD 1450. Certified to CSA C22.2 NO 68.

IMPORTANT ELECTRICAL INFORMATION

Attention

Use only a 3-wire extension cord that has a

3-blade grounding plug and a 3-slot receptacle

that will accept the plug on the product.

Make sure your extension cord is in good condition. When

using an extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating.

A 14 or 12 gauge cord is recommended (see chart). If an

extension cord is to be used outdoors, it must be marked with

“SJW” or “SJTW”. For example, a designation of SJTW would

indicate that the cord would be appropriate for outdoor use.

cord gauge

Maximum cord length

12

150 feet

14

100 feet

Titan Tool accessory extension cords recommended:

P/N 0090241

20 foot extension cord

P/N 0090242

35 foot extension cord