!! The following instructions are restricted to qualified

personnel only !!

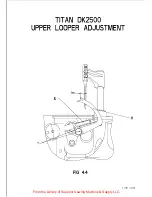

With the upper looper in its bottom dead centre, make sure the outer end of the upper

looper aligns with the centre of the screw (25557V) that fixes the needle bar bushing

(Fig. 4.3).

Should this not be the case, loosen the two 25698VL screws (see part list – Upper

looper mechanism) and bring the upper looper in the right position as described in

previous paragraph 4.2b.

Turn the hand-wheel by hand for the upper looper to reach its upper position and

make sure the outer end of the upper looper extends for 5 mm beyond the edge of

the needle (see figure 4.5).

Should this not be the case, loosen the two 25698VL screws and bring the upper

looper in the right position as described in previous paragraph -

b. replacing the upper looper

3. The lower looper

a. Preparatory work

To gain access to the lower looper, proceed as follows:

•

Turn to figure 2.1, titled ‘

Threading Diagram’,

and locate the screw-on/off fitting

cap with the wording OIL marked on it.

•

Loosen and remove the cap. This will give the operator access to the lower

looper.

b. Replacing the lower looper

To replace a worn out lower looper, proceed as follows:

•

Use an open ended spanner n° 6 to retain the base

W

(Fig. 4.5) of the lower

looper into position while using an open ended spanner n° 10, loosening the nut

K

for

½ a turn (MAXIMUM).

•

Gently unscrew the worn out lower looper and remove it.

•

Fit in the replacement lower looper.

Note:

Prior to fixing the lower looper into position, perform positioning of the lower

looper relative to the recess on the rear of the needle as described below (see figure

4.2-4.3-4.5).

Turn the hand-wheel by hand while making sure that when the lower looper is

passing beyond the needle, both flat faces on both parts are parallel. The lower

looper can under no condition touch the needle !

In the event of exact parallelism as shown in figure 4.2, retain the lower looper

S

in

position using an open ended spanner n° 6, while screwing the block nut

K

(figure

4.5) through ½ a turn, using an open ended spanner n° 10.

From the Library of Superior Sewing Machine & Supply LLC