10

description of unit / starting operation

Impact 400

3.5

TechNIcAl DATA

voltage

220~240 VAC, 50/60 Hz

max. current consumption

5.3 A

power cord

See page 82

max. operating pressure

207 bar (20.7 MPa)

volume flow at 12 mpa (120 bar) with water

1.62 l/min

max tip size

0.021 inch – 0.53 mm

max. temperature of the coating material

43°C

max viscosity

20.000 MPa·s

Weight

13.6 kg

Special high-pressure hose

6,35 mm, 15 m - 1/4” - 18 NPSM

Dimensions (l x W x h)

441 x 324 x 415 mm

vibration

Spray gun does not exceed 2.5m/s

2

max sound pressure level

80 dB*

* Place of measurement: 1 m distance from unit and

1.60m above floor, 12 MPa (120 bar) operating pressure,

reverberant floor

3.6

TrANSporTATIoN IN vehIcle

Secure the unit with a suitable fastening.

4

STArTINg operATIoN

4.1

hIgh-preSSure hoSe, SprAy guN AND

SepArATINg oIl

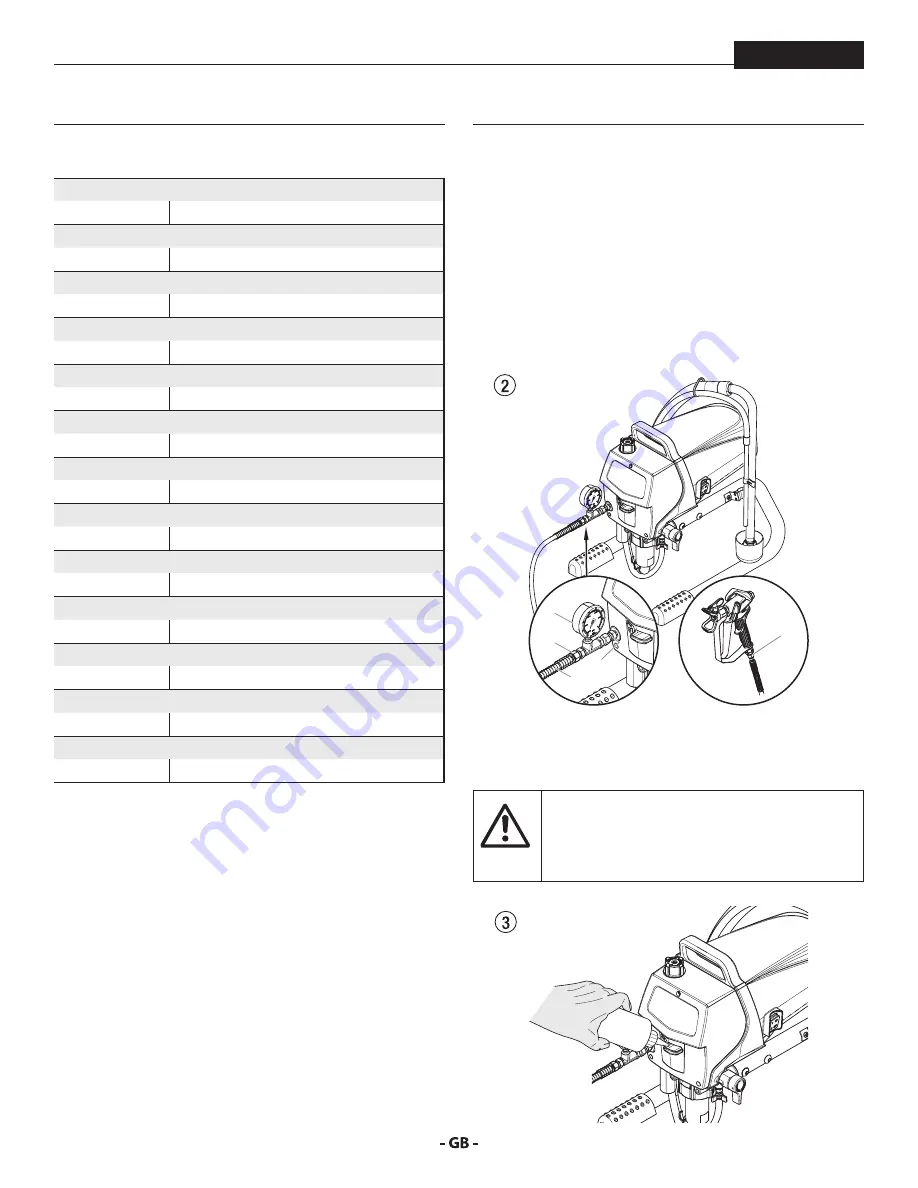

1. If equipped, screw the pressure gauge (1) to the coating

material outlet (Fig. 2, Item 2).

2. Screw the high-pressure hose (3) to the coating material

outlet (Fig. 2, Item 4).

3. Screw the spray gun (5) with the selected tip onto the

high-pressure hose.

4. Tighten the union nuts at the high-pressure hoses firmly

so that coating material does not leak.

1

4

2

3

5

5. Fill the oil cup with Piston Lube (Fig. 3). Do not use too

much Piston Lube, i.e. ensure that no Piston Lube drips

into the coating material container.

Attention

Piston Lube prevents increased wear and tear to

the packings.