10

description of unit

Impact 540

3

DeScrIpTIoN of uNIT

3.1

AIrleSS proceSS

The main areas of application are thick layers of highly viscous

coating material for large areas and a high consumption of

material.

A piston pump takes in the coating material by suction and

conveys it to the tip. Pressed through the tip at a pressure of

up to a maximum of 221 bar (22.1 MPa), the coating material

is atomised. This high pressure has the effect of micro fine

atomisation of the coating material.

As no air is used in this process, it is described as an AIRLESS

process.

This method of spraying has the advantages of finest

atomisation, cloudless operation and a smooth, bubble-free

surface. As well as these, the advantages of the speed of work

and convenience must be mentioned.

3.2

fuNcTIoNINg of The uNIT

In the following there is a short description of the technical

construction for better understanding of the function.

Titan Impact 540 units are electrically driven high-pressure

spraying units.

A gear unit transfers the driving force to a crankshaft. The

crankshaft moves the pistons of the material feed pump up and

down.

The inlet valve is opened automatically by the upwards

movement of the piston. The outlet valve is opened when the

piston moves downward.

The coating material flows under high pressure through the

high-pressure hose to the spray gun. When the coating material

exits from the tip it atomizes.

The pressure control knob controls the volume and the

operating pressure of the coating material.

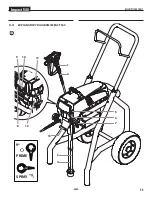

3.3

legeND for explANATory DIAgrAm

ImpAcT 540

1. Spray gun

2. High-pressure hose

3. Return hose

4. Suction hose

5. Oil level gauge

6. Oil button

7. Relief valve

Lever position vertical – PRIME (

k

circulation)

Lever position horizontal – SPRAY (

p

)

8. ON/OFF switch

9. Control panel indicators

10. Pressure control knob

11. Oil cup for Piston Lube (Piston Lube prevents increased

wear of the packings)

12. Manometer

13. Pail bracket