42

PowrPlast 600

GB

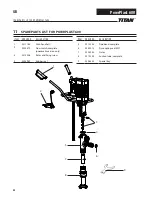

6.8

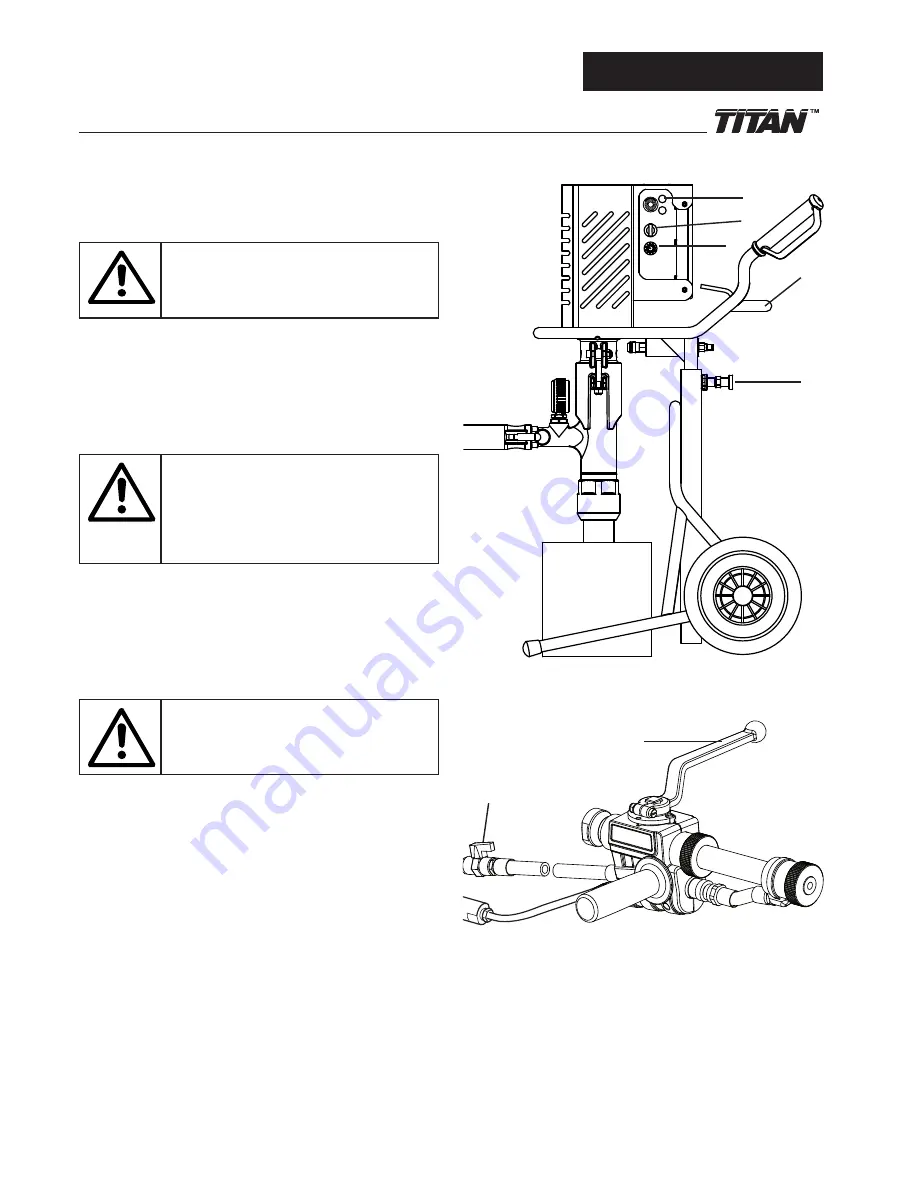

PRePARING tHe MORtAR SPRAyING MAcHINe

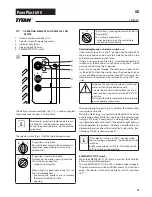

(FIG. 16)

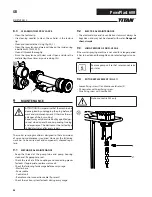

Recommended sliding means for the mortar hose

Water is not sufficient as a sliding means.

Danger of clogging!

Use cellulose paste (e.g. Metylan wallpaper

paste, art no. 2312136)

• Fill 2–3 l cellulose paste into a suitable container.

• Connect the mortar spraying machine to the mains supply.

The operation light (1) shows operational readiness.

• Place container under mortar spraying machine.

• Pull safety pin (2) to the rear and press down mortar spray

-

ing machine frame (3) until machine engages in the bottom

position.

Risk of injury from escaping material.

Before switching on, always check that the

material tap on the spray lance is closed

(material tap points forwards).

close material tap whenever stopping

work.

• Set selector switch (4) to “A”.

• Set delivery volume controller (5) to „3“.

6.8.1

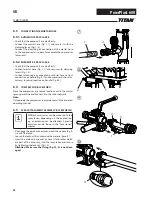

RINSe tHe MORtAR HOSe

(AutOMAtIc SPRAy LANce)

•

Close the air flow regulator (fig. 17.2).

Do not bend the mortar hose!

Protect it against damage, for exam-

ple against being driven over as well as

against sharp objects and edges.

• Hold the spray lance over the container.

• Open material tap (Fig. 17, 1) on spray lance (material tap at

90° to spray lance), the mortar spraying machine is switched

on.

•

If cellulose paste comes out of the tip, close the material tap

(fig. 17, 1) (material tap points forwards).

• Replace container and lubricant with container and coating

material.

• Hold spray lance above container with cellulose paste.

• Open material tap (Fig. 17, 1) on spray lance.

• As soon as coating material exits from spray lance,

close material tap (Fig. 17, 1).

The mortar spraying machine is now full and ready.

commIssIonIng

A

F

R

POWER

ERROR

1

2

3

4

5

1

2