45

PowrPlast 600

GB

cleaning the pump unit

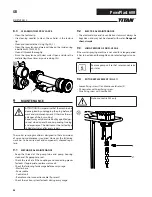

Once the pump pipe has been removed from the pump unit,

the pump housing (10) up to the seals can be cleaned with a

jet of water and suitable bottle brush.

Thoroughly clean rotor (11), stator (9) and pump pipe (8) with

water and a brush too if necessary.

Then spray rotor (11) and stator (9) with a suitable pump lu

-

bricant.

Keep the thread of the pump housing and the pump tube

clean so that leaking after the assembly is avoided.

Dismantling

Mortar spraying machine must be depres-

surised.

If necessary, set the selector switch briefly

to “R” (reverse).

Watch the manometer ––> 0 bar.

Wear safety goggles.

Only the person operating the machine may

remove the pump unit.

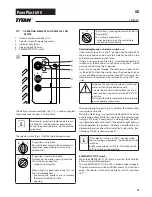

• Move selector switch (1) to “A” and set delivery volume con

-

troller (2) to „0“.

• Pull safety pin (3) to rear to release lock. Pull PowrPlast 600

up by its frame (4) until the machine engages in the top po

-

sition.

•

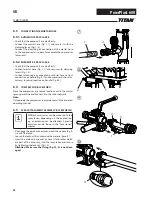

Loosen the union nut on the pump tube using the special

key (approx. a one-quarter turn)

• Remove nuts from locking pins (5). Fold up locking pins so

that they remain in contact with magnets in handle.

• Set delivery volume controller (2) to 1 or 2.

• Firmly hold pump unit (6) with one hand. Move selector

switch (1) to “R” position (reverse gear) and hold there. As

soon as the pump unit (6) has released, move selector switch

to “A” and remove pump unit.

•

Disconnect mains plug.

• Loosen/unscrew pump pipe (8) from pump unit (6) using

the special key provided.

• Remove stator (9) from pump pipe.

shuttIng Down anD cleanIng

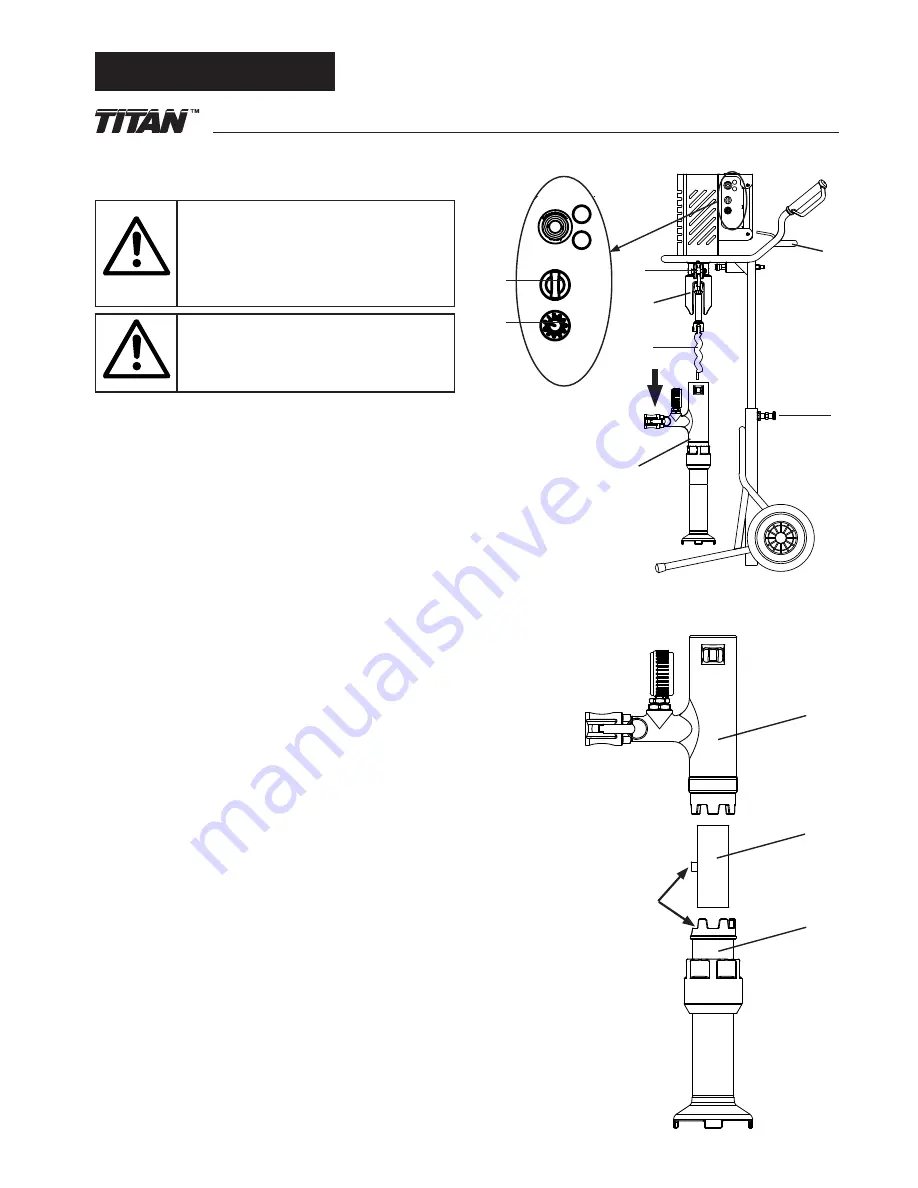

Mounting

Insert stator (9) in pump pipe (8) such that the journal sits in

the largest recess.

Use special key to screw pump pipe back onto pump unit (6).

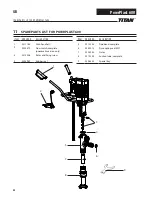

6

9

8

A

F

R

POWER

ERROR

1

4

3

11

A

F

R

POWER

ERROR

2

5

6

10