© Titan Tool Inc. All rights reserved.

11

1. Using a wrench, loosen and remove the inlet valve

housing from the pump manifold.

2. Clean out any debris in the inlet valve housing and

examine the valve housing and seat. If the seat is

damaged, reverse or replace the seat.

3. Using a 5/16” hex wrench, loosen and remove the outlet

valve retainer from the piston rod.

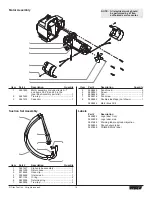

Outlet Valve

Retainer

Outlet Valve

Seat

Outlet Valve

Ball

Outlet Valve

Cage

Piston Rod

NOTE: always service the

outlet valve with the

piston rod attached

to the pump. This will

prevent the piston rod

from rotating during

disassembly of the

outlet valve.

4. Clean out any debris and

examine the valve housing

and seat. If the seat is

damaged, reverse or replace the seat.

5. Remove, clean, and inspect the outlet valve cage and

outlet valve ball. Replace if they are worn or damaged.

6. Reassemble the valves by reversing the steps above.

Repacking the Fluid Section

1. Remove the foot valve assembly using the steps in the

“Servicing the Valves” procedure above.

NOTE: The outlet valve does not need to be

disassembled from the piston rod for this

procedure.

Slider Assembly

Connecting Pin

Retaining Ring

Retainer Nut

Piston Guide

Upper Packing

Assembly

Pump Manifold

Pump Manifold

Mounting Screw

Piston Rod

Lower Packing

Assembly

Spacer

2. Slide the retaining

ring up on the slider

assembly to expose

the connecting pin.

3. Push the connecting

pin forward through

the slider assembly

and piston. The

connecting pin will

fall into a recessed

area of the gear box

housing where it can

be retrieved.

4. Using 3/8” a hex

wrench, loosen and

remove the two pump

manifold mounting

screws.

5. Pull the pump manifold

down off of the gear

box housing.

6. Slide the piston rod out

through the bottom of

the pump manifold.

7. Loosen and remove

the retainer nut and

piston guide from the

pump manifold.

8. Remove the upper and

lower packings from

the pump manifold.

9. Clean the pump

manifold and install

the new upper and

lower packings. Refer to the illustration below for proper

packing orientation.

Install lower packings

with raised lip and O-ring

facing up.

Install upper packing

with raised lip and O-ring

facing down.

O-Ring

O-Ring

Raised Lip

Raised Lip

10. Inspect the piston rod for wear and replace if necessary.

11. Insert the piston guide into the retainer nut. Thread the

retainer nut into the pump manifold until it is hand tight.

12. Slide the piston guide tool (included in the repacking kit)

over the top of the piston rod and insert the piston rod

through the bottom of the pump manifold. Using a rubber

mallet, tap the bottom of the piston rod lightly until the

piston rod is in position in the pump manifold.

NOTE: coat the piston guide tool and the piston rod

with grease before inserting them into the pump

manifold.

13. Using a wrench, tighten the retainer nut securely.

14. Position the pump block underneath the pump housing

and push up until it rests against the pump housing.

When the connecting pin hole on the piston rod lines up

with the hole in the slider assembly, insert the connecting

pin.

15. Slide the retaining ring down over the connecting pin.

IMPORTaNT: Make sure the transducer is aligned properly

with the hole in the pump manifold during reassembly.

Improper alignment may cause damage to the transducer

gasket.

16. Thread the pump manifold mounting screws through the

pump manifold and into the gear box housing. Tighten

securely.

17. Reassemble the inlet valve assembly into the pump

manifold.

18. Insert the elbow on the suction set assembly into the

bottom of the inlet valve housing. Push the retaining ring

up into the groove inside the inlet valve housing to secure

the suction set assembly in position. Push the return hose

onto the return hose fitting on the pump manifold and

secure in position with the return hose clamp.

19. Place the front cover on the gear box housing and secure

in position using the four front cover screws.

20. Turn on the sprayer by following the procedure in the

“Operation” section of this manual and check for leaks.

NOTE: Repacking kit P/N 0551533 is available. For best

results use all parts supplied in this kit.