8

© Titan Tool Inc. All rights reserved.

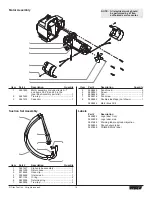

Replacing the PRIME/SPRay valve

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 0507690.

1. Drive the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly from the pump manifold.

4. Make sure the gasket is in place and thread the new

valve housing assembly into the pump manifold. Tighten

securely with a wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam

with the pump manifold using the dowel pin.

6. Line up the hole on the valve stem with the hole in the

valve handle.

7. Insert the groove pin into the valve handle and through the

valve stem to secure the valve handle in position.

Dowel Pin

Groove Pin

Valve Stem

Gasket

Pump

Manifold

Valve Housing

Assembly

Valve

Handle

Cam Base

Replacing the Filters

Pump Filter

1. Loosen and remove the filter housing.

2. Pull the filter from the pump manifold.

NOTE: If the filter breaks off in the pump manifold, use a

small wood screw to remove.

3. Inspect the filter seal. Based on inspection, clean or

replace the seal.

4. Push the new or cleaned filter into the pump manifold.

5. Slide the filter housing over the filter and thread it into the

pump manifold until secure.

Filter Housing

Filter

Filter Seal

Pump Manifold

Gun Filter

1. Pull down on the bottom of the trigger guard and swing it

away from the handle.

2. Slide off the handle and unscrew the handle tube from the

gun head.

3. Turning clockwise, unscrew the filter from the gun body.

NOTE: Left-handed threads require turning the filter

clockwise to remove.

4. Screw the new or cleaned filter counterclockwise into the

gun head.

5. Slide the handle tube over the filter and screw it into the

gun head.

6. Slide the handle over the handle tube and reattach it to

the gun head.

7. Secure the trigger guard back in position on the bottom of

the handle.

NOTE: For more detail, part number information, and

complete assembly drawings, please see the

LX-80 Platinum Gun Owner’s Manual (P/N 313-

2302).

Replacing the Motor assembly

1. Perform the Pressure Relief Procedure and unplug the

sprayer.

2. Remove the four motor cover screws. Remove the motor

cover.

3. Remove the four heat sink assembly screws. Pull the heat

sink assembly away from the gear box housing.

4. Disconnect the five wires from the relay that is mounted

on the inside of the heat sink assembly.

5. Remove the three relay mounting screws from the heat

sink assembly. Remove the relay.

6. Using the three relay mounting screws, install the new relay

onto the heat sink assembly. Tighten the screws securely.

7. Connect the five wires to the new relay (refer to the

electrical schematic in the Parts List section of this manual).

8. Using the four heat sink assembly screws, install the heat

sink assembly onto the gear box housing. Tighten the

screws securely.

9. Disconnect the black and red wires coming from the gear

box housing. Disconnect the black and red wires from the

capacitors. Disconnect the black and red wires from the

motor.

10. Loosen and remove the four motor mounting screws.

11. Pull the motor out of the gear box housing.

NOTE: If the motor will not dislodge from the pump

housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the front

of the motor crankshaft that extends through

the slider assembly.

12. With the motor removed, inspect the gears in the gear

box housing for damage or excessive wear. Replace the

gears, if necessary.

13. Install the new motor into the gear box housing.

NOTE: Rotate the motor fan manually until the armature

gear engages with the mating gear in the gear

box housing.

14. Secure the motor with the four motor mounting screws.

15. Push the new capacitors into their clip on the new motor.