Maintenance

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce

the risk of an injection injury, injury from moving

parts or electric shock. Always unplug the

sprayer before servicing!

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

Phillips Screwdriver

3/8" Hex Wrench

Needle Nose Pliers

5/16" Hex Wrench

Adjustable Wrench

1/4" Hex Wrench

Rubber Mallet

3/16" Hex Wrench

Flat-blade Screwdriver

5/32” Hex Wrench

1. Before repairing any part of the sprayer, read the

instructions carefully, including all warnings.

IMPORTANT: Never pull on a wire to disconnect it. Pulling

on a wire could loosen the connector from the wire.

2. Test your repair before regular operation of the sprayer to be

sure that the problem is corrected. If the sprayer does not

operate properly, review the repair procedure to determine if

everything was done correctly. Refer to the Troubleshooting

Charts to help identify other possible problems.

3. Make certain that the service area is well ventilated in

case solvents are used during cleaning. Always wear

protective eyewear while servicing. Additional protective

equipment may be required depending on the type of

cleaning solvent. Always contact the supplier of solvents

for recommendations.

4. If you have any further questions concerning your TITAN

Airless Sprayer, call TITAN:

Customer Service (U.S.) .......................

1-800-526-5362

Fax ................................................

1-800-528-4826

Customer Service (Canada) ..................

1-800-565-8665

Fax ................................................

1-905-856-8496

Customer Service (International)...........

1-201-337-1240

Fax ................................................

1-201-405-7449

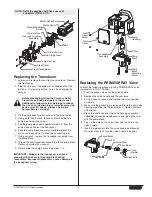

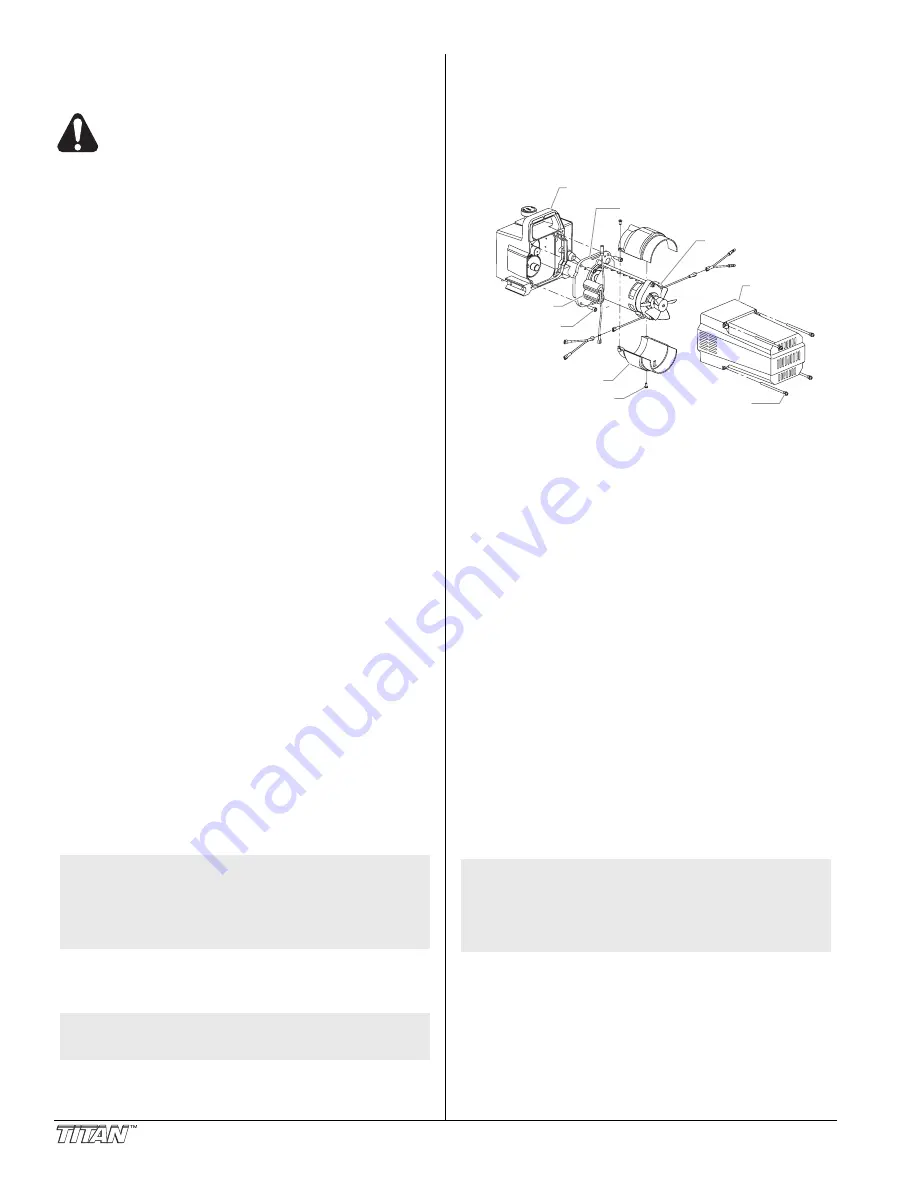

Replacing the Motor

1. Unplug the sprayer.

2. Loosen and remove the four motor cover screws.

Remove the motor cover.

3. Disconnect the black and red wires coming from the pump

housing. Disconnect the black and red wires from the

capacitors. Disconnect the black and red wires from the

motor.

4. Remove the capacitors from their mounting clip.

5. Loosen and remove the four motor mounting screws.

6. Pull the motor out of the pump housing.

7. With the motor removed, inspect the gears in the pump

housing for damage or excessive wear. Replace the

gears, if necessary.

8. Install the new motor into the pump housing.

9. Secure the motor with the four motor mounting screws.

10. Using the double-sided tape and the tie wrap that came

with the new motor, attach the capacitors to the motor.

NOTE: Rotate the motor fan manually until the

armature gear engages with the mating gear in

the pump housing.

NOTE: If the motor will not dislodge from the pump

housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the

front of the motor crankshaft that extends

through the connecting rod.

8

© Titan Tool Inc. All rights reserved.

a. Place the double-side tape on the capacitors, and stick the

capacitors onto the motor. The capacitors should be

positioned in the same spot as they were on the old motor.

b. Wrap the tie wrap around the capacitors and the motor.

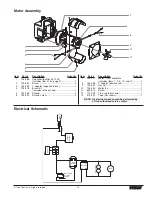

11. Reconnect the wires (refer to the electrical schematic in

the Parts List section of this manual).

12. Slide the motor cover over the motor. Secure the motor

cover with the four motor cover screws.

Replacing the Motor Brushes

Perform this procedure using Motor Brush Kit P/N 704-276.

1. Loosen and remove the four motor cover screws.

Remove the motor cover.

2. Loosen and remove the two shroud screws. Remove the

shroud.

3. Using a small screwdriver, pry off the two plastic brush

covers.

4. Disconnect the black and red wires from the motor

brushes. Remove the motor brushes.

5. Install the new motor brushes and snap on the plastic

brush covers.

6. Reconnect the black and red wires from the motor

brushes (refer to the electrical schematic in the Parts List

section of this manual).

7. Position the shroud over the motor fan. Secure the

shroud with the two shroud screws.

8. Slide the motor cover over the motor. Secure the motor

cover with the four motor cover screws.

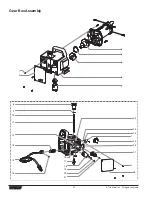

Replacing the Gears

1. Loosen and remove the four motor cover screws.

Remove the motor cover.

2. Disconnect the black and red wires coming from the pump

housing.

3. Loosen and remove the four motor mounting screws.

4. Pull the motor out of the pump housing.

5. Inspect the armature gear on the end of the motor for

damage or excessive wear. If this gear is completely

worn out, replace the entire motor.

6. Remove and inspect the 2nd stage gear for damage or

excessive wear. Replace if necessary.

7. Remove and inspect the gear and crank assembly for

damage or excessive wear. Replace if necessary.

8. Reassemble the pump by reversing the above steps.

During reassembly, make sure the thrust washers is in

place.

NOTE: If the motor will not dislodge from the pump

housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the

front of the motor crankshaft that extends

through the connecting rod.

BLACK

BLACK

BLACK

RED

RED

RED

Motor Cover

Brush Cover

Motor

Pump Housing

Capacitors

Motor Mounting

Screw

Shroud

Shroud Screw

Motor Cover

Screw