OPERATION INSTRUCTIONS

Warning! Before using your sander be

sure to read the instruction manual

carefully.

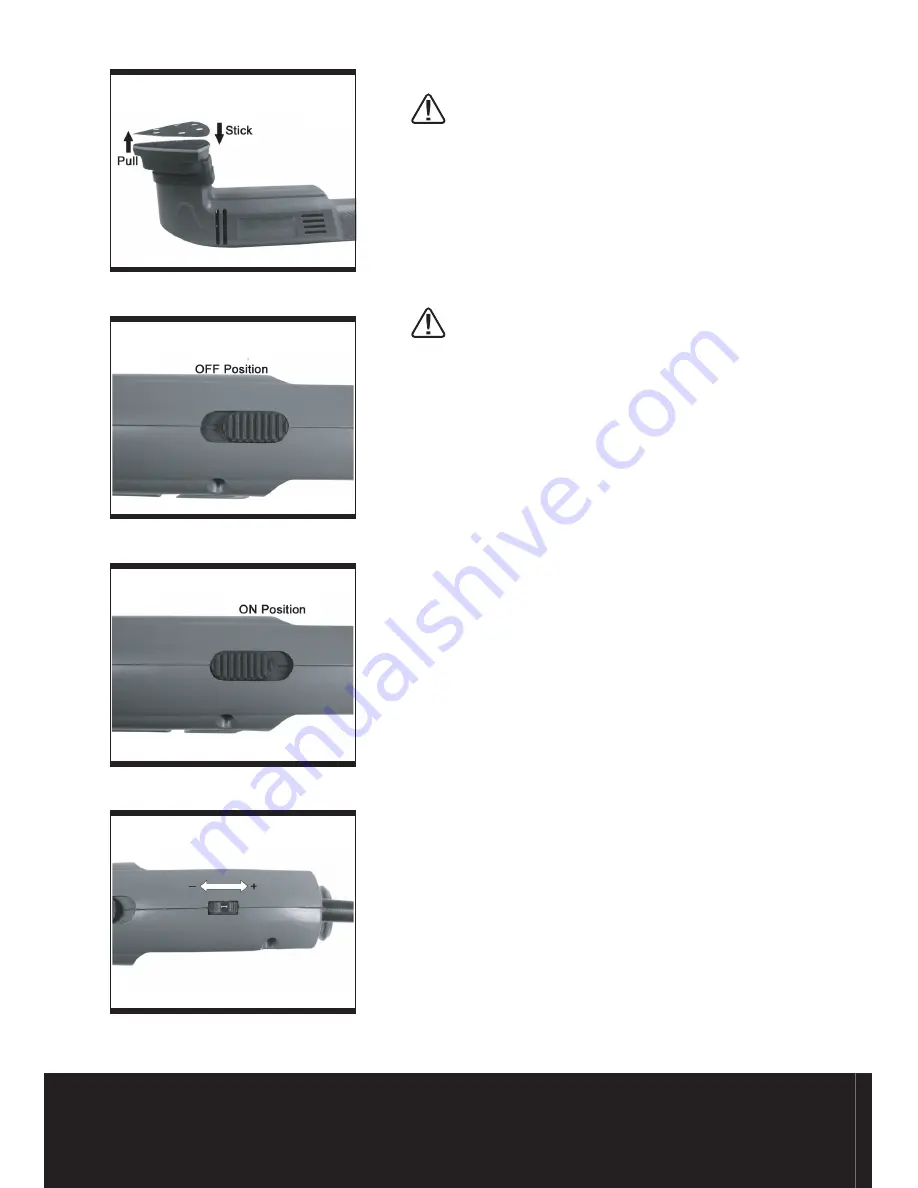

1. FITTING THE SANDING PAPER

(See Fig2)

(a)Make sure the plug is disconnected from the

mains supply.

(b)Align the dust extraction holes in the sanding

pad with the holes in the base and press firmly

together (see fig2).

(c)Spare sanding sheets can be purchased from

any good DIY store.

Warning! Always switch off and unplug

from the mains before making any

adjustment.

2. SWITCHING ON AND OFF

(See Fig3a & 3b)

To operate the detail sander,put the plug into

mains supply(make sure On/Off switch is in Off

position see fig3a), grip sander firmly with both

hands and switch on (see fig3b). At all times, let

the sander do the work - do not force it or apply

excessive pressure, otherwise damage may

occur to the abrasive paper causing it to tear or

wrinkle. Preferably, use a light circular motion.

The sander can also be used on slightly curved

surfaces, owing to the rubber-made base plate.

The shaped base plate can be used to access

awkward corners / areas.

3. VARIABLE SPEED CONTROL

(See Fig4)

According to the material to be sanded and

sanding paper specification, you can adjust

sanding speed by turning the speed selector

wheel. The greater speed is indicated by the

higher figure. The little speed is indicated by the

lower figure.

4. USING THE SANDER

(See Fig5)

Note:

If you see some sparks flashing in the

ventilation slots do not panic, this is normal and

will not damage the tool.

Be sure to hold the sander firmly whilst it is on

and apply it gently to the work; it may kick on first

contact. Hold the sander so that it is flat on the

work and move slowly, preferably in parallel line

movements. When you first turn it on, make sure

that your finger remains on the switch so you can

STOP the sander in case there is a problem.

Fig 3a

Fig 3b

Fig 2

Fig 4

Summary of Contents for SF280E

Page 1: ...280W DETAIL SANDER SF280E SAFETY AND OPERATING MANUAL...

Page 13: ......