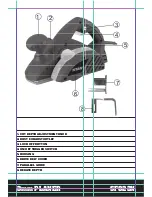

3mm PLANER

SF823N

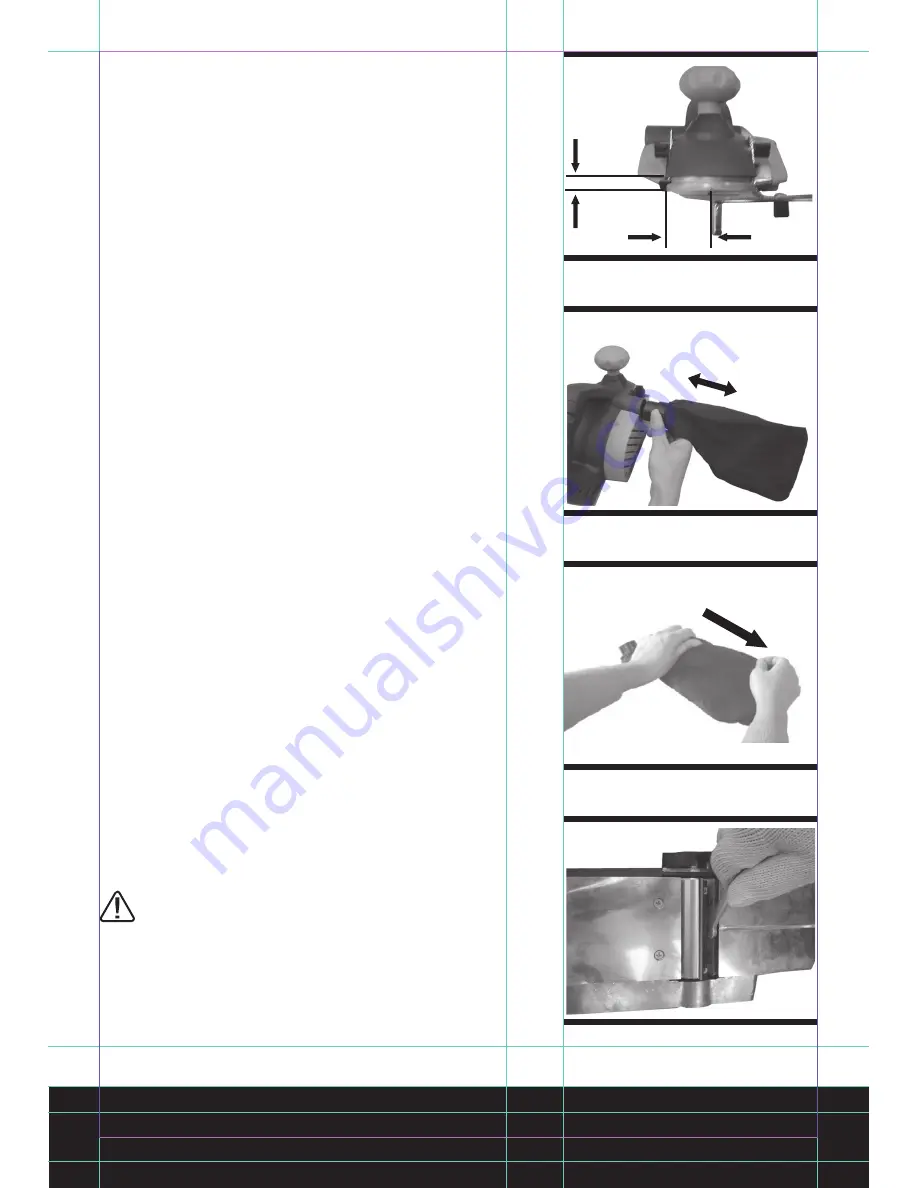

Depth of

rebate cut

Blade

edge

Width of

rebate cut

Fig 9

Insert

Remove

Fig 10

screw fully.

The width and depth of rebate cut

(see fig9)

The width of rebate cut is adjustable by moving

the parallel guide. The depth of rebate cut is

determined by the moving the depth guide, and

the number of passes made along the workpiece.

7. USING THE DUST COLLECTION BAG

(see

fig10)

Your planer is equipped with a dust bag for

collection of wood chips in the work area.

Make sure the zipper on the bag is fully closed. To

fit the dust bag, simply insert the tube end of the

bag into the dust extraction outlet. Then switch on

and start planing.

Cleaning dust exhaust outlet and emptying

the dust bag

(see fig11)

After using your planer for an extended period

of time or when planing wet green timber, chips

may build-up in the dust exhaust outlet and

require clearing. Chip build-up restricts air flow

and causes the motor to overheat. Turn off the

planer and remove the dust bag from the dust

exhaust outlet. Clean the chip and dust

exhaust outlet of your planer with a small piece

of wood. Do not use your hands or fingers. Unzip

the dust bag and empty all chips from it. Ensure

collar is free from debris.

We recommend emptying the dust bag

every 3-6 minutes.

8. BLADE REPLACEMENT

(seefig12,fig13,

fig14,fig15)

After blades are replaced, check that they are

parallel and in the same line as the rear base

plate. Check this with a straight edge (ruler). To

adjust the blades firstly loosen the three screws

on the blade holder. Then turn the socket head

screw clockwise and the blade will rise up.Turn the

socket head screw anti clockwise and the blade

will be lowered. When adjustment is complete

tighten the three screws.

WARNING!

Before replace the blades

remove mains plug from mains supply.

Always put on a glove.

Secure your planer in an upside down position.

Using the blade spanner provided, loosen the

three installation screws on the drum by turn

clockwise.

Note:

Do not over loosen the screws. If screws

Unzip the dust bag

Fig 11

Fig 12