2

P/N 313-001, REV C © 2002 © Titan Tool Inc. All rights reserved.

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

insecticides, and other materials can be harmful if

inhaled or come in contact with body. Vapors can

cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read all

instructions supplied with the mask to be sure it will provide

the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating

manufacturer.

HAZARD: GENERAL - Can cause severe injury or property

damage.

PREVENTION:

• Read all instructions and safety precautions before operating

equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act

(OSHA). These standards, particularly part 1910 of the

General Standards and part 1926 of the Construction

Standards should be consulted.

• Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specifications and safety devices of the pump

manufacturer.

• Before each use, check all hoses for cuts, leaks, abrasion or

bulging of cover. Check for damage or movement of

couplings. Immediately replace hose if any of those

conditions exist. Never repair a paint hose. Replace with a

grounded high-pressure hose.

• All hoses, swivels, guns, and accessories must be pressure

rated at or above 5000PSI/350 BAR.

• Do not spray outdoors on windy days.

• Wear clothing to keep paint of skin and hair.

• Always unplug cord from the outlet before working on

equipment.

Installation

Always use a tip safety guard for added protection against

injection. Beware that the guard alone will not prevent

injection. Never cut off tip guard! Always engage gun trigger

lock when the gun is not in use. Before servicing equipment,

consult owner’s manuals and observe all warnings.

Pressure Relief Procedure

Never attempt to install, change, or clean tip or tip guard

without first performing the “Pressure Relief Procedure.”

1. Move the spray unit’s ON/OFF switch to the OFF position.

2. Turn the spray unit’s pressure control knob counterclockwise

to its lowest setting.

3. Hold the metal part of the gun firmly to

the side of a metal container to ground

the gun and avoid a build up of static

electricity.

4. Trigger the gun into the container to

remove any pressure that may still be in

the hose.

5. Lock the gun by turning the gun trigger

lock to the locked position.

6. Turn the spray unit’s PRIME/SPRAY

valve to the PRIME position.

Trigger lock

in locked position.

WARNING

WARNING

Assembling the Gun and Tip Assembly

Before attaching a gun to a grounded high pressure airless

hose, make sure that the airless spray unit is turned off and

that fluid pressure has been relieved from the system.

Assembling the Gun

1. Connect a high pressure fluid hose to the material inlet on

the gun. Tighten securely with a wrench.

2. With the tip and tip guard off the gun, start the spray unit.

Flush the system according to the manufacturer’s

recommendation. Inspect the unit to make sure that all

fittings are secure and that there are no leaks.

3. Perform the “Pressure Relief Procedure” described earlier in

this manual.

Assembling the Tip

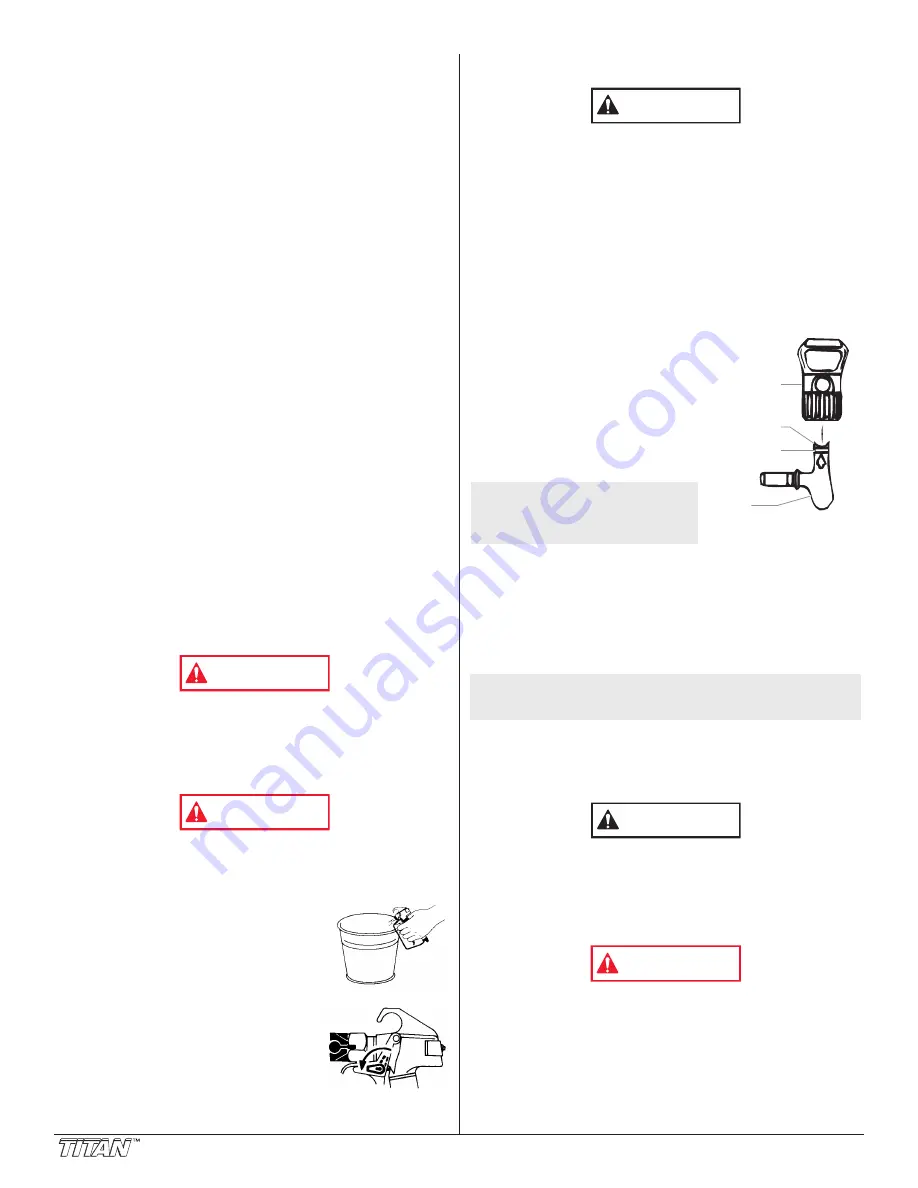

1. Using the tip handle, insert the tip

seal and tip gasket into the back

of the tip guard. Press in for final

adjustment.

2. Insert the tip into the slot on the

tip guard.

3. Thread the tip guard onto the

gun. Position the tip guard in the

desired spraying position, then

tighten securely by hand.

Operation

1. Make sure the arrow on the tip handle is pointing in the

forward direction for spraying.

2. Start the spray unit.

3. Adjust the fluid pressure on the spray unit until the spray is

completely atomized. Always spray at the lowest pressure

necessary to get the desired results.

4. To clear a clogged tip:

a. Rotate the tip 180º so that the arrow on the tip handle is

pointing opposite the spray direction.

b. Trigger the gun once so that the pressure can blow the

clog out.

Never pull the trigger more than once at time with the tip in

the reverse position.

c. Continue this procedure until the tip is clear of the clog.

Changing a Tip

Tips can be removed and replaced easily without disassembling

the gun.

Never attempt to install, change, or clean the tip or tip guard

without first performing the “Pressure Relief Procedure.”

1. Perform the “Pressure Relief Procedure” described earlier in

this manual.

2. Remove the tip from the slot on the tip guard.

3. Insert the new tip into the slot on the tip guard. The arrow

on the tip handle should be pointing in the forward direction

for spraying.

WARNING

CAUTION

NOTE: The spray tip determines the size of spray pattern

and coverage. When more coverage is needed, use

a larger tip instead of increasing fluid pressure.

NOTE: The arrow on the tip

handle should be

pointing in the forward

direction for spraying.

Tip Seal

Tip Guard

Tip Gasket

Tip

CAUTION