10

© Titan Tool Inc. All rights reserved.

Troubleshooting - airless Spraying

condition

Possible cause

correction

A. Poor spray pattern and / or tails at

top and bottom of the spray pattern.

Worn or incorrect tip and/or insufficient

atomization.

Hose size or length is too small or too

long.

Dirty filter.

Be sure the tip is not worn. Increase

pressure. Lower viscosity. Reduce

surface tension by increasing hose size to

minimize pressure drop through hose and/

or reduce hose lengths. Use preorifice

disc (H disc).

B. The gun drips or throws a drop at

the beginning or end of the spray

pattern.

Needle may not be seating correctly.

Increase spring tension.

Needle-orifice combination should be

factory relapped. Needle packing may

be too tight. Loosen as much as possible

without leakage.

Turn adjusting screw on back of gun

clockwise to increase tension or use the

green HP spring Part # 701-098.

C. Spray tip stops up frequently.

Particles too large for spray tip are passing

filter and/or gun screen.

Use 100 mesh gun screen instead of 50

mesh for small spray tips. Use 100 mesh

screen in pump filter. Strain paint.

D. Spray pattern changes with pump

cycle.

Restrictions in the fluid system.

Check gun and pump filter screens.

Always clean screens before they load up.

E. Irregular flow of material. One

stroke faster than the other.

Packings are worn or valve balls are not

seating.

Restriction in the siphon system.

Check siphon hose assembly to be sure no

air is entering, then recheck all threaded

fittings for leakage. See Troubleshooting

- Fluid Section for additional service

information.

F. Spitting.

Air in system.

Dirty gun.

Inspect for siphon hose leak.

Disassemble and clean gun.

G. Gun does not spray any fluid.

Suction hose leak.

No paint.

Plugged foot valve.

Plugged filters or tip.

Ball check valve stuck open.

Inspect for siphon hose leak.

Check fluid supply.

Remove, clean, inspect foot valve.

Clean filters or tip.

Clean and inspect pump ball check valve.

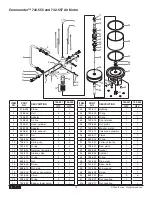

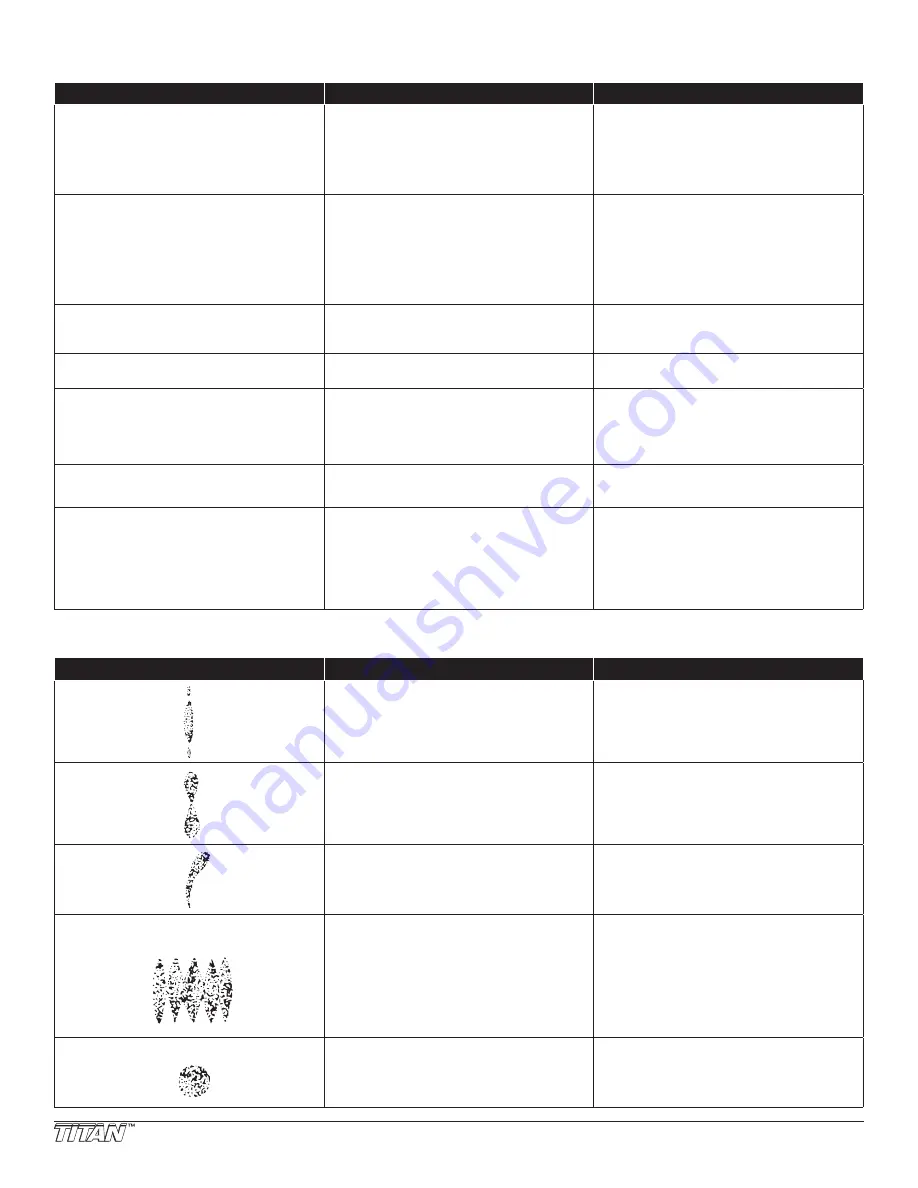

Troubleshooting - Spray Patterns

condition

Possible cause

correction

A. Tails

Inadequate fluid delivery.

Fluid not atomizing correctly.

Increase fluid pressure. Change to small

tip orifice size. Reduce fluid viscosity.

Reduce hose length.

Clean gun and filter(s). Reduce number of

guns using pump.

B. Hour glass

Inadequate fluid delivery.

Same as above.

C. Distorted

Plugged or worn nozzle tip.

Clean or replace nozzle tip.

D. Pattern expanding and contracting

(surge)

Suction leak.

Pulsating fluid delivery.

Inspect for siphon hose leak.

Change to a smaller tip orifice size.

Install pulsation dampener in system or

drain existing one. Reduce number of

guns using pump.

Remove restrictions in system, clean tip

screen if filter is used.

E. Round pattern.

Worn tip.

Fluid too heavy for tip.

Replace tip.

Increase pressure. Thin material. Change

nozzle tip.