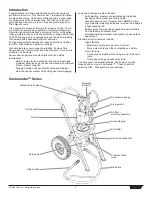

© Titan Tool Inc. All rights reserved.

7

Startup

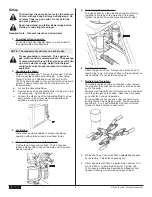

1. Close the self relieving shutoff valve. The figure below

shows the handle in the closed position.

2. Start the compressor.

3. Drain the Petcock by pushing it off center.

4. adjusting the air regulator:

The air motor is designed for a maximum air input of 120

psi. Turn the T-Handle clockwise to increase pressure

and counter-clockwise to decrease pressure. Verify the

amount of air pressure by reading the air gauge.

Paint pressure is directly proportional to the amount of air

pressure.

Example: Commander 30:1

100 psi reading at air gauge = 3000 psi at pump outlet.

Consult the materials manufacturer for guidelines in establishing

the correct air pressure.

NOTE: using a higher pressure than required will only

wear out tips. use the guidelines in establishing

the lowest pressures for proper atomization.

Once the correct air pressure has been established, lock the air

regulator by tightening the lock nut.

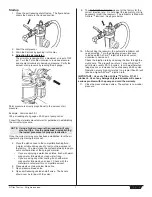

5. Place the siphon hose in the compatible flushing fluid.

A water soluble oil was used to test your new sprayer at

the factory. You must clean the system before spraying to

avoid contamination of the sprayed material.

• If you are spraying a water-based latex, flush with warm

soapy water followed by a clean water rinse.

• If you are using any other coating, flush with warm

soapy water followed by a solvent. Check with the

material manufacturer for a compatible solvent.

6. Place waste container below bleed line.

7. Open pressure bleed valve.

8. Open self-relieving vented shutoff valve. The handle

should now be in line with the valve.

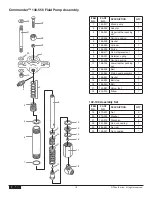

9. The

automatic Lubricator

was set at the factory for the

correct injection rate. Do not adjust the lubricator until it is

necessary to refill the reservoir. The lubricator is filled with

AirCare™ lubricant. See figure below.

10. After refilling the reservoir, the automatic lubricator will

need adjusting. Turn the adjusting screw clockwise

to increase the AirCare™ injection rate and counter-

clockwise to decrease it.

Check the injection rate by observing the flow through the

sight dome. The proper flow rate is 1 drop of AirCare™

per minute or every 90-125 cycles. In cold weather when

icing may occur, increase to one drop every 50-60 cycles.

Operation at very high cycle rates (i.e. greater than 60) will

require a higher AirCare™ injection rate.

IMPORTaNT: use only Titan aircare™ Part No. 311-011

lubricant. use of any detergent-type lubricants will cause a

serious problem with the pump and void the warranty.

11. Close the pressure bleed valve. The system is now under

pressure.