6

© Titan Tool Inc. All rights reserved.

Operation

Fueling (gas engine)

Gasoline is extremely flammable and is explosive

under certain conditions.

• ALWAYS turn the engine off before refueling.

• Refuel in a well-ventilated area.

• Do not smoke or allow flames or sparks in the refueling

area or where gasoline is stored.

• Do not overfill the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

• Be careful not to spill fuel when refueling. Spilled fuel or

fuel vapor may ignite. If any fuel is spilled, make sure the

area is dry before starting the engine.

• Avoid repeated or prolonged contact with skin or breathing

of vapor.

• Keep out of the reach of children.

Fuel Specifications

• Use automotive gasoline that has a pump octane number

of 86 or higher, or that has a research octane number of

91 or higher. Use of a lower octane gasoline can cause

persistent “pinging” or heavy “spark knock” (a metallic

rapping noise) which, if severe, can lead to engine

damage.

NOTE: If “spark knock” or “pinging” occurs at a steady

engine speed under normal load, change brands

of gasoline. If spark knock or pinging persists,

consult an authorized dealer of the engine

manufacturer. Failure to do so is considered

misuse, and damage caused by misuse is not

covered by the engine manufacturer’s limited

warranty.

Occasionally you may experience light spark

knock while operating under heavy loads. This

is no cause for concern, it simply means your

engine is operating efficiently.

• Unleaded fuel produces fewer engine and spark plug

deposits and extends the life of the exhaust system

components.

• Never use stale or contaminated gasoline or an oil/

gasoline mixture. Avoid getting dirt, dust, or water in the

fuel tank.

Gasolines containing alcohol

If you decide to use a gasoline containing alcohol (gasohol), be

sure its octane rating is at least as high as that recommended

by the engine manufacturer. There are two types of “gasohol”:

one containing ethanol, and the other containing methanol. Do

not use gasohol that contains more than 10% ethanol. Do not

use gasoline containing methanol (methyl or wood alcohol)

that does not also contain co-solvents and corrosion inhibitors

for methanol. Never use gasoline containing more than 5%

methanol, even if it has co-solvents and corrosion inhibitors.

NOTE: Fuel system damage or engine performance

problems resulting from the use of fuels that

contain alcohol is not covered under the

warranty. The engine manufacturer cannot

endorse the use of fuels containing methanol

since evidence of their suitability is incomplete at

this time.

Before buying gasoline from an unfamiliar

station, try to find out if the gasoline contains

alcohol. If it does, confirm the type and

percentage of alcohol used. If you notice any

undesirable operating characteristics while using

a gasoline that contains alcohol, or one that you

think contains alcohol, switch to a gasoline that

you know does not contain alcohol.

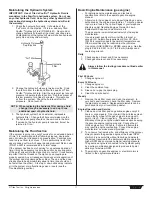

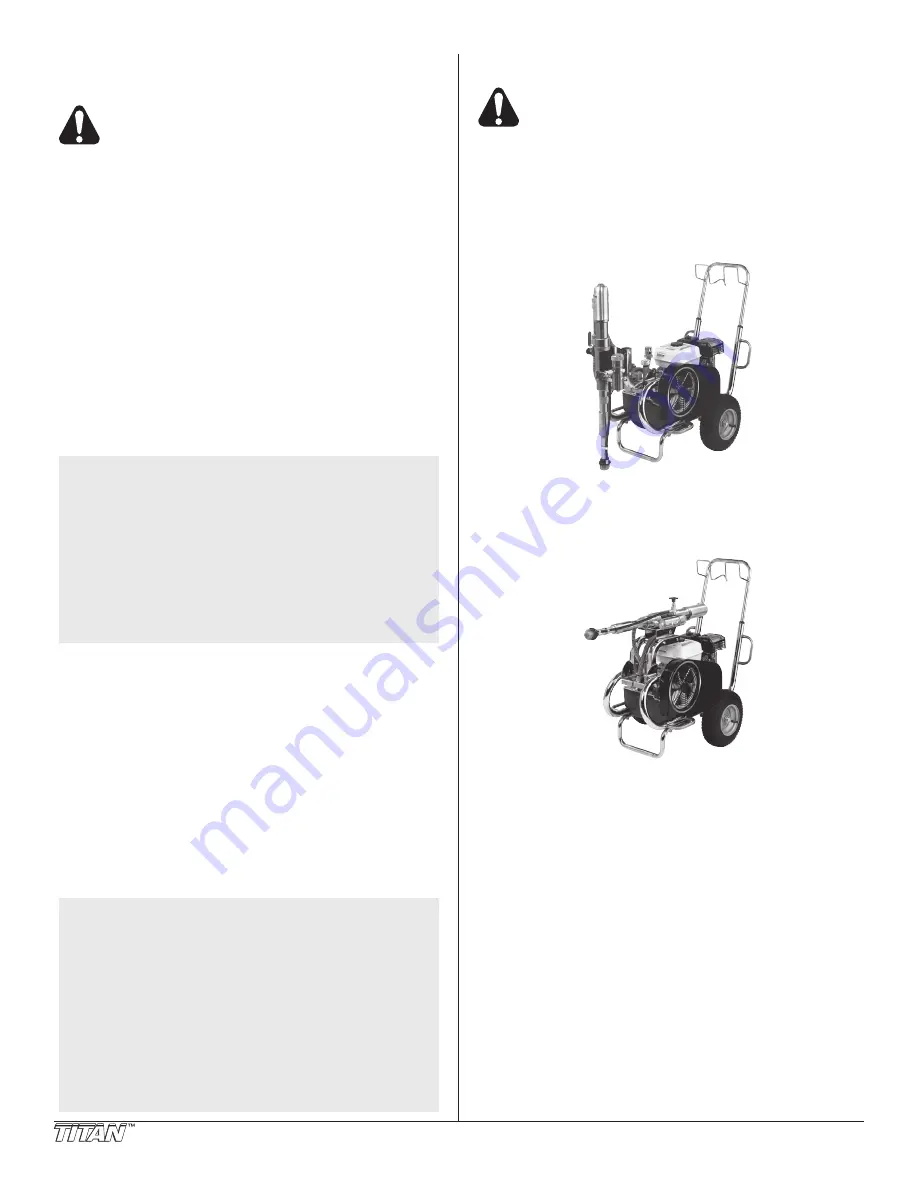

Operating the Swing cart

use caution when operating the swing cart. Keep

fingers and feet clear of moving parts.

The swing cart allows the motor/pump assembly to be rotated

between two positions.

Position #1: Working Position

The vertical position of the motor/pump assembly is the working

position. This position allows complete submersion of the siphon

tube/foot valve on the fluid section into a paint bucket. The

maximum height paint bucket that can be used is 28 1/8” (71.4

cm).

Position #2: Transporting Position

The horizontal position of the motor/pump assembly is the

transporting position. This position allows easy removal of

the paint bucket and creates a sprayer height of 30” (76.2

cm) for ease of transportation.

Use the following procedure to change the position of the motor/

pump assembly.

1. Holding the handle grip with one hand, pull the locking

pin out of the locking hole on the cart with the other hand.

This allows the motor/pump assembly mounted on the

swing cart frame to move from one position to the other.

2. Let go of the locking pin once it is free of the locking hole.

3. Move the motor/pump assembly to the desired position.

The locking pin is spring loaded and will automatically

engage the locking hole on the swing cart at the new

position.