EN

26

TTT831HDC-Li

by TITAN

Getting

started...

Setup

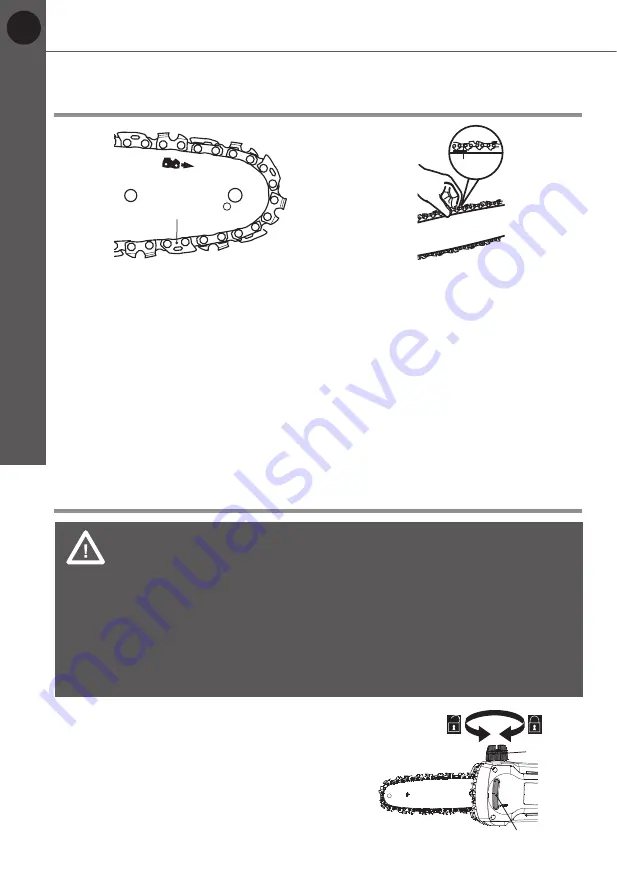

Chain ‘tie straps’

Fig. 11

2-4 mm

Fig. 12

23

23a

Fig. 13

3. Adjust the tension if you find that the saw chain (20) is too loose or tight.

4. Slightly loosen the locking wheel (21), then screw the tension screw (26)

with the multi tool (31) in or out to adjust the tension pin (28) / guide bar

(19) towards the left or right until the chain ‘tie straps’ are just touching the

bottom edge of the guide bar (19), hold it in the position.

5. Pull the saw chain (20) along the top of the guide bar (19) by gloved hand

from one end to the other, several times. The saw chain (20) should feel

tight but still move freely.

6. After the adjustment, re-tighten the locking wheel (21).

Chain lubrication

WARNING!

The product is not filled with chain oil. It is essential

to fill the product with chain oil before using it! Never operate the

product without chain oil as this will result in extensive damage to

the product! Operating the saw chain dry or with too little chain oil

will decrease cutting efficiency, shorten the product life span and

cause rapid wear to the saw chain and guide bar from overheating!

Insufficient chain oil is evident by smoke or bar discoloration!

Adequate lubrication of the saw chain during cutting operations is

essential to minimise friction with the guide bar!

1. Place the product on a stable, level

surface with the oil tank cap (23) facing

upward. We recommend laying a non-

flammable sheet under the product.

2. Unscrew and remove the oil tank cap (23)

(Fig. 13).

Before you start

Chain ‘tie straps’

Fig. 11

2-4 mm

Fig. 12

23

23a

Fig. 13

Summary of Contents for TTT831HDC

Page 56: ......