13

RL20-2 /

Manual

Titgemeyer / 10342EN1121 / 1

English

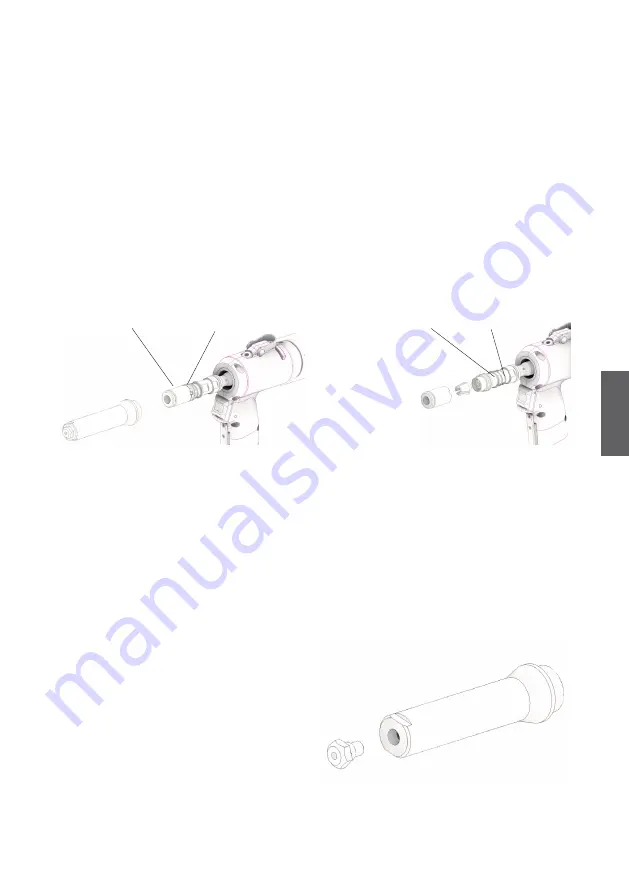

— Lightly grease the new jaws on the

outer circumference and insert them

(teeth to the axis) in the jaw case.

Screw the head back on the adapter.

The lock automatically secures the

jaw case against release. Tighten only

to the last possible tooth of the lock.

Do not use a wrench for tightening

!

Jaw case

Spacer

Counter nut

Galvanized

lock

It could damage the lock.

— Carefully screw on the front nosecap

and tighten it with wrench no. 16.

— Check the x-dimension value (chapter

18. Setup of the X-dimension)

Nosepiece Disassembly and Assembly

Disconnect the tool from the com-

pressed air

Use a wrench no. 16 to hold the tool’s

nosecap by the flats at the front and

loosen the nosepiece using wrench

no. 11. Then loosen the entire nose-

cap using wrench no. 16. Remove the

nosecap and manually unscrew the

nosepiece

Take the selected nosepiece and manu-

ally screw it onto the removed nosecap.

Mount the nosecap back onto the tool

and tighten with wrench no. 16 (flats)

and no. 11 (nosepiece)