16

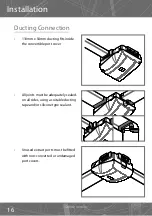

All joints must be adequately sealed,

on all sides, using a suitable ducting

tape and/or silicone type sealant.

•

Unused extract ports must be fi tted

with non-converted or undamaged

port covers.

•

Ducting Connection

110mm x 54mm ducting fi ts inside

the convertible port cover

•

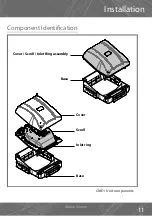

Installation

Online Version