TJM Vehicle Mount Compressor Installation and User Manual

For product warranty please refer to our website www.tjm.com.au

File: F-17800.docx

Page 2 of 12

29/05/2019

Table of Contents

TJM Vehicle Mount Compressor ........................................................................................................... 1

1.0

1.0

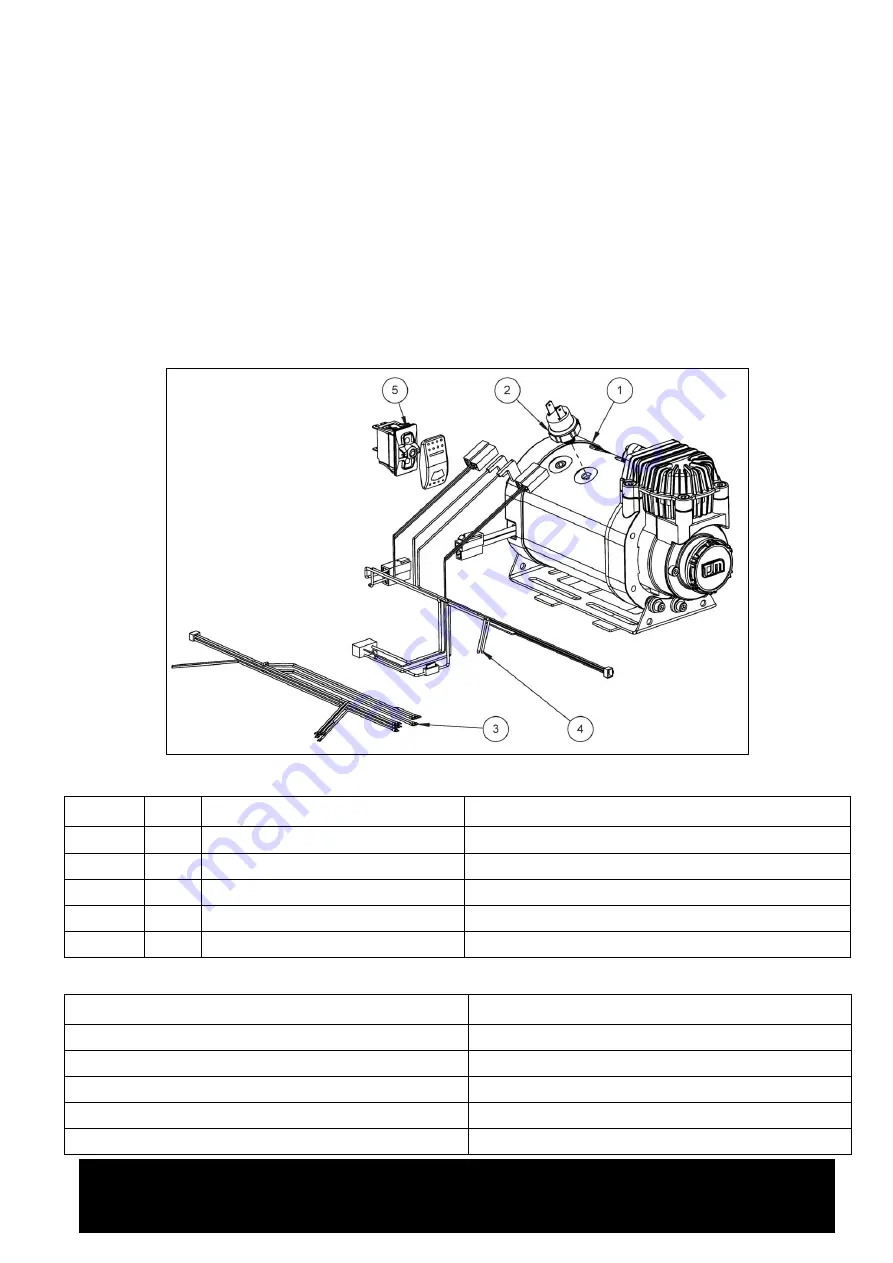

Compressor Specifications

1.1

Bill of Material

Item No. QTY

Part Number

Description

1

1

F-17615

Compressor

2

1

013COMPVPS120-90

Pressure Switch

3

1

F-14002

Wiring Harness

–

Cabin

4

1

F-17799

Wiring Harness

–

Engine Bay

5

1

013COMPVACTSWITCH

Compressor Activation Switch Kit

1.2

Electrical Specification

Voltage

12 V DC

Current Draw (0 Bar / 0 PSI)

26 A

Current Draw (200 kPa / 29 PSI)

33 A

Fuse Type and Rating

Maxi 40 A

IP Rating

54

Motor thermal cut-off

105°C