10

www.tkequip.com

(956) 796 - 9411

9. SERVICE INSTRUCTIONS

1.

Never service or lubricate the unit engine while running.

2.

After servicing the unit, restore and fasten all guards, shields, and covers to their original

positions.

3.

Never drain oil into the ground, into open streams, or down sewage drains.

4.

To make sure your equipment is always in good working condition before using, carry

out the maintenance inspection in accordance with the Maintenance Schedule.

ENGINE

See engine owner´s manual maintenance schedule.

If lost please visit

https://engines.honda.com/parts-and-support/owners-manuals

information.

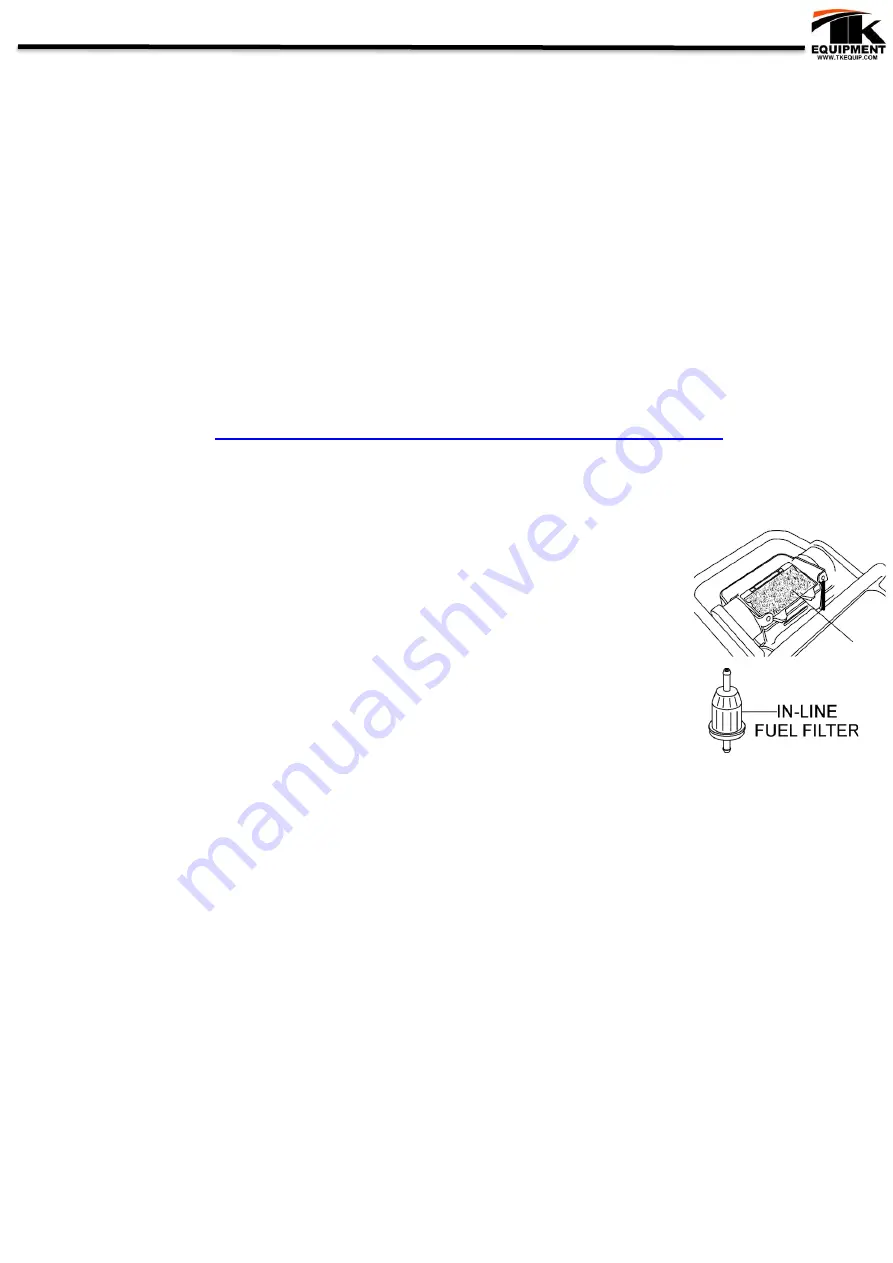

AIR FILTER - SPARK PLUG &

1. The air filter element should be cleaned because a clogged air cleaner can

cause poor engine starting, lack of power and shorten engine life substantially.

Remove the air cleaner cover. Loosen and remove the 2 screws that hold the

cover to the air cleaner assembly. If the primary element (Figure 13) is dirty,

wash it with gasoline or kerosene. Then dip it in engine oil (SAE10W-30) and

wring the element so that 25 to 30 cc of engine oil remains on the element.

2. Inspect in-line fuel filter and replace if necessary.

3. Remove & clean the spark plug, then adjust the spark gap to 0.024~0.028 inch

(0.6~0.7 mm).

4. Remove the oil drain plug on foot housing and drain the oil. Refill with approximately 0.8 qt.

(0.75 liter) of 10W-30 SE, SF or higher-grade motor oil. Oil should be midway insight glass.

Break-in oil should be changed after first 50 hours.

10.

MAINTENANCE SCHEDULE

THESE INSPECTION INTERVALS ARE FOR OPERATION UNDER NORMAL CONDITIONS.

ADJUST YOUR INSPECTION INTERVALS BASED ON THE NUMBER HOURS THIS

MACHINE HAS BEEN IN USE AND ITS PARTICULAR WORKING CONDITIONS.

1.

Check all hardware after the first 5 hours of use.

Check for loose screws including tightness.

2.

Check oil daily. Look after leakage of fuel or oil.

3.

Change oil after 5 (five) hours of use and every 25 hours after first change.

Refer to engine manual for oil grades.