6

www.tkequip.com

(956) 796 - 9411

HEAD PROTECTION

Wear O.S.H.A. specified safety helmets.

EYE PROTECTION

Wear O.S.H.A. specified eyes shields, safety glasses, and sweat bands.

DUST PROTECTION

Wear O.S.H.A. specified dust mask or respirator.

OPERATOR

Keep children and bystanders off and away from the equipment.

For details on safety rules and regulations in the United States, contact your local Occupational Safety

and Health Administration (O.S.H.A.) office. Equipment operated in other countries must be operated

and serviced in accordance and compliance with any and all safety requirements of such country. The

publication of these safety precautions is done for your information does not by the publication of

these precautions, imply or in any way represent that these are the sum of all dangers present near

equipment. If you are operating this unit it is your responsibility to ensure that such operation is in full

accordance with all applicable safety requirements and codes. All requirements of the United States

Federal Occupational Safety and Health Administration Act must be met when operated in areas that

are under the jurisdiction of that United States Department.

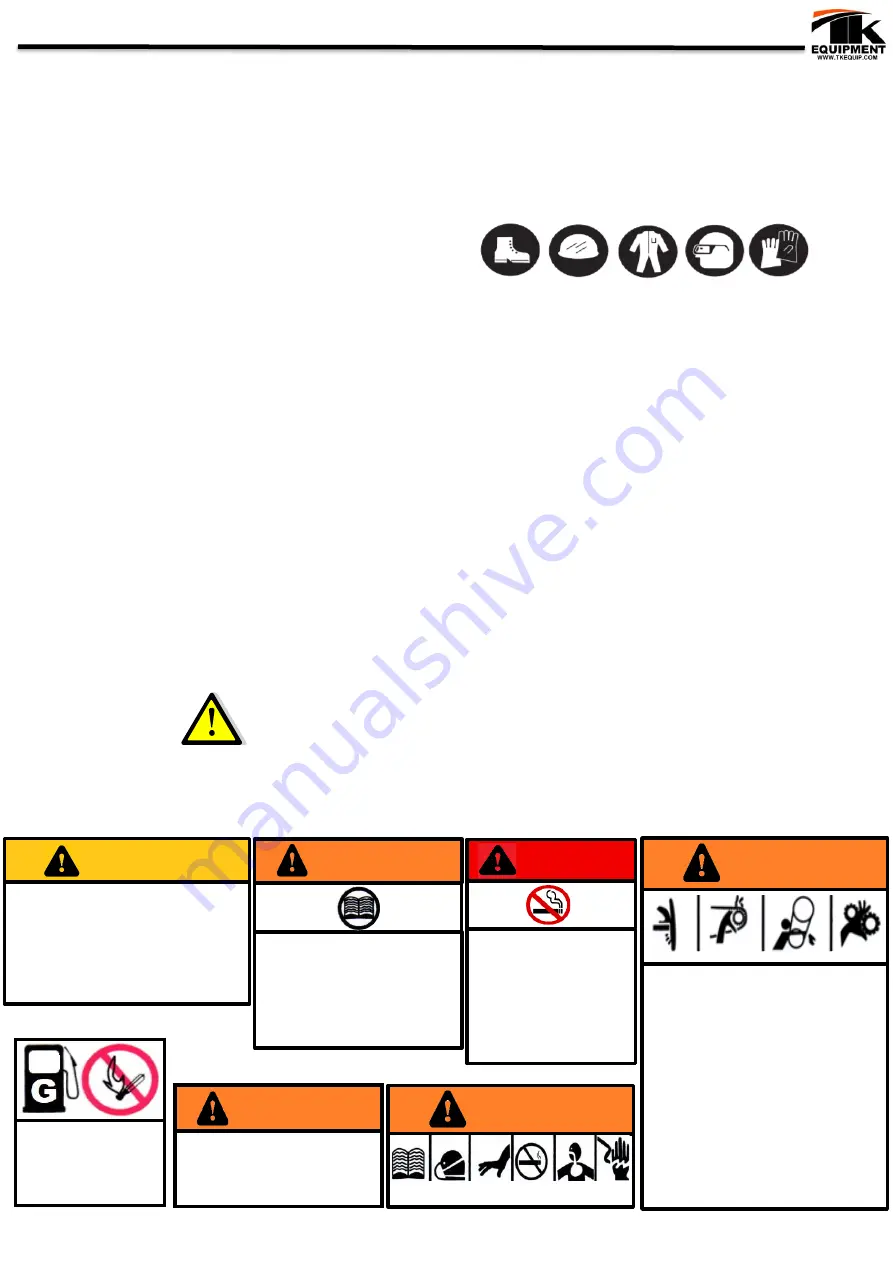

5. SAFETY NOTICE & DECALS

The

"SAFETY ALERT SYMBOL"

is used to call attention to items or operations that may be dangerous

to those operating or working with this equipment. These symbols can be found throughout the

manual and on the unit itself. Please read these warnings and cautions carefully.

READ SAFETY DECALS CAREFULLY

Carefully read and follow all safety decals. Keep them in good conditions. If they become aged,

replace as required. If repainting,

REPLACE ALL

decals. Decals are available from your

authorized Distributors. Decals are not shown to scale.

CAUTION

2-PERSON LIFT REQUIRED

TO LIFT UNIT FROM

GROUND ON/OFF VEHICLE

201155

WARNING

201005

WARNING

ROTATING PART HAZARD

KEEP AWAY

TO PREVENT SERIOUS INJURY OR DEATH ROTATING PARTS:

1.

INSTALL, CLOSE AND SECURE ALL GUARDS,

SHIELDS AND HOODS BEFORE OPERATING.

2.

DO NOT PLACE HANDS IN DRUM UNLESS THE

MOTOR OR ENGINE IS OFF AND THE POWER

CORD UNPLUGGED OR THE KILL SWITCH

ACTIVATED.

3.

KEEP HANDS, FEET, HAIR AND LOOSE

CLOTHES AWAY FROM MOVING PARTS.

201003

USE GASOLINE

FUEL ONLY

201152

WARNING

MISSING GUARD HAZARD

INSTALL, CLOSE AND SECURE ALL GUARDS,

SHIELDS AND HOODS BEFORE OPERATING.

201004

WARNING

IMPROPER OPERATION OF THIS EQUIPMENT CAN

CAUSE SERIOUS INJURY OR DEATH.

READ OPERATOR’S MANUAL

SUPPLIED WITH THIS

MACHINE BEFORE OPERATION OR SERVICING.

MODIFICATION OR ALTERATION OF THIS MACHINE

WILL VOID MANUFACTURER’S WARRANTY.

DO NOT ALTER OR MODIFY THIS MACHINE WITHOUT

THE

EXPRESS

WRITTEN

CONSENT

OF

THE

MANUFACTURER.

201154

DANGER

NG

FIRE HAZARD

NO SMOKING

TO PREVENT SERIOUS INJURY OR

DEATH FROM FIRE:

1.

DO NOT SMOKE WHEN REFUELING

2.

KEEP SPARKS, FLAMES, AND HOT

MATERIAL AWAY FROM FLAMMABLE

SUBSTANCES.

201005