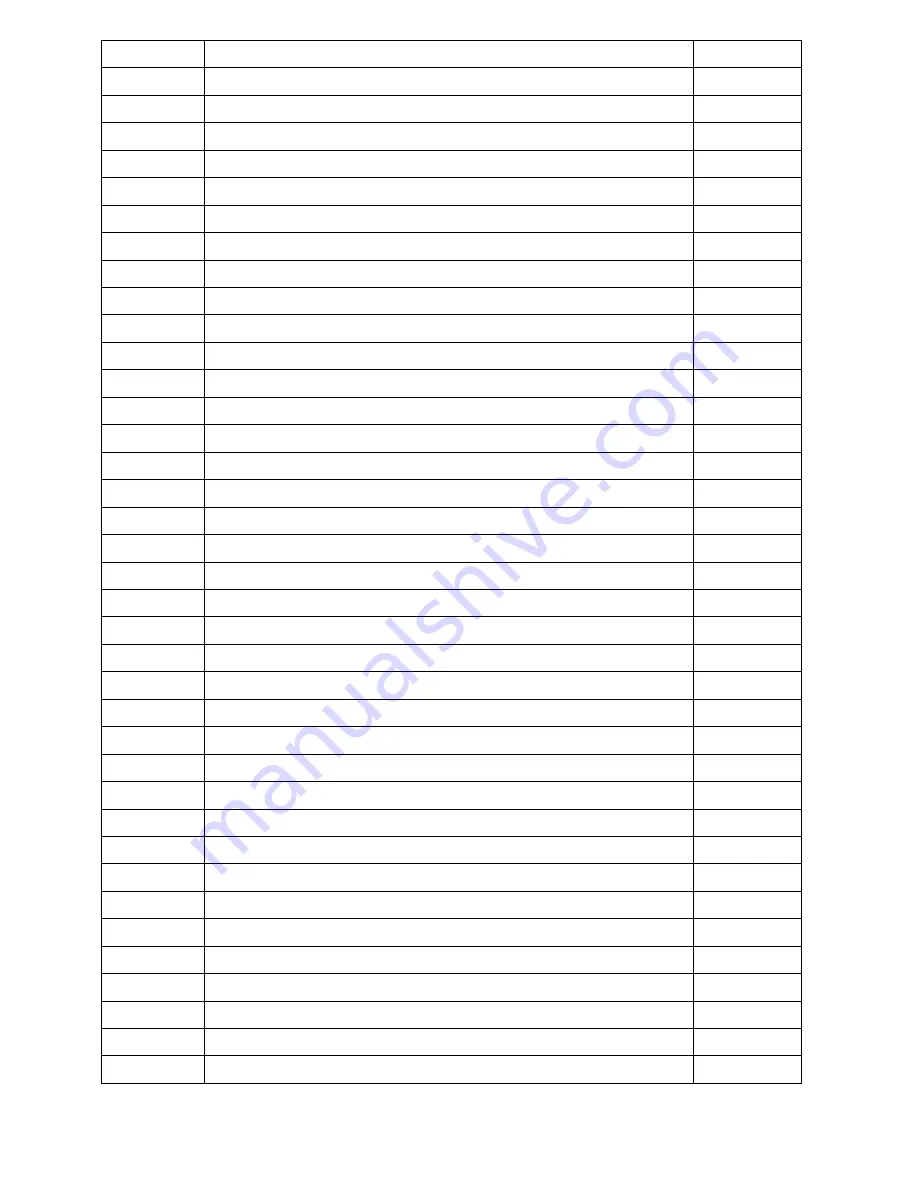

13

NO.

Description

Q'TY

36

Belt (762mm J8)

1

37

Pulley (235mm)

1

38

Magnet

1

39

Belt (1092mm J8)

1

40

Front Aluminum Upright Cover

1

41

Rear Aluminum Upright Cover

1

42

Air Pressure Bar

1

43

Seat Adjustment Lever

1

44

Fixed Stand

1

45

Spacer

1

46

Cable

1

47

Cable Spring

1

48

Roller Axle

1

49

Stand Spring

1

50

Spacer Stand

1

51

Arc Washer

1

52

Resistor

1

53

Controller

1

54

Right Mounting Plate

1

55

Left Mounting Plate

1

56

Idler Spring

1

57

Washer (

ψ

10.6

×ψ

60

×

2.0t)

1

58

Idler Arm

1

59

Axle Connection Cap

1

60

Bearing 6004ZZ

8

61

Idler Wheel Spacer

1

62

One Way Pulley (51)

1

63

One Way Bearing (2520)

1

64

Axle

1

65

Right Crank

1

66

Left Crank

1

67

Crank Shaft

1

68

Eye Bolt

4

69

Tension Bracket

2

70

Square Key (6

×

6

×

15mm)

1

71

E Ring

1

72

Crescent Ring

4

Summary of Contents for 9GU

Page 1: ...ASSEMBLY MANUAL 9GU COMMERCIAL UPRIGHT BIKE...

Page 2: ......

Page 4: ...3...

Page 17: ...EXPLODED DRAWING...

Page 18: ...17...

Page 19: ...18...